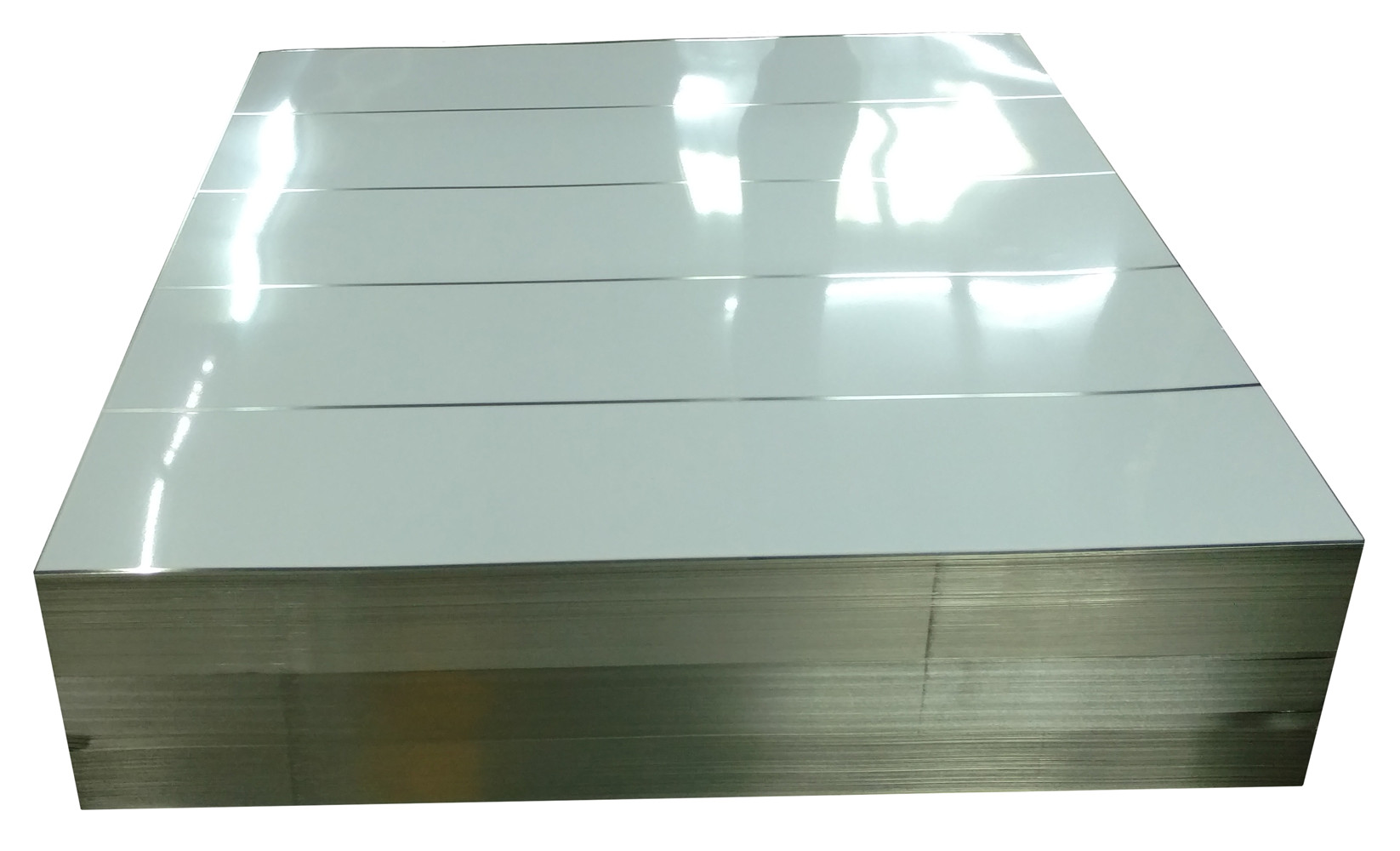

The full name of tin sheet steel is tin-plated steel sheet, referred to as tin plate metal. It is a low-carbon steel sheet coated with pure tin on both sides. The thickness of tin plate metal is generally 0.23 mm to 0.25 mm, and it is silver-gray. From a cross-sectional perspective, the tin sheet steel structure is an intermediate layer substrate (about 0.2 mm thick), followed by an alloy layer (about 0.1 μm thick), a tin layer (about 0.1 μm to 1 μm), and an iron oxide layer (thickness) About 0.001 mm to 0.01 microns), oil film layer (about 0.001 mm to 0.01 microns thick) and other components. The role of the oil film is to prevent the surface of the tin sheet steel from being scratched due to friction during stacking, bundling or transportation, and to ensure that the tinplate surface state does not adversely affect printing or coating. At present, foreign countries have strengthened the management of tin plate metal manufacturing to prevent failures such as non-sticking with ink or coating and degradation of adhesion performance. The tin plate metal should be processed before screen printing. The purpose is to remove processing defects, improve the aesthetic effect of the surface, change the finish of the metal surface, and improve tin sheet printing suitability.