Specification of Printed Tinplate 5 Litre Dome Paint Tin:

Product name | Printed Tinplate 5 Litre Dome Paint Tin |

Features | Eco-friendly and recyclable, durable and long lasting use |

Material | 0.20-0.35mm thickness first grade tinplate |

Size | Customized according to your requirements |

Color | Various colors for your selection, or customized color |

Printing | CMYK or PMS offset printing, with glossy or matt varnish |

Packing | Each in a polybag, several pcs in one carton, other safe packing is according to your requirement |

Certificate | EN71, SGS, ISO |

Sample | Free samples, express freight collect |

Customization | Customized size, shape, printing, embossing logo and 3D embossing are all welcome, artwork is accepted |

Main Product | food tins, tea tins, candy tins, chocolate tins, wedding favor boxes, health care boxes, electronics boxes, medicine boxes, stationery boxes, facial mask boxes, cosmetic boxes, beautiful wrapped gift boxes etc. |

Panit Show

Product Detail

Internal Can

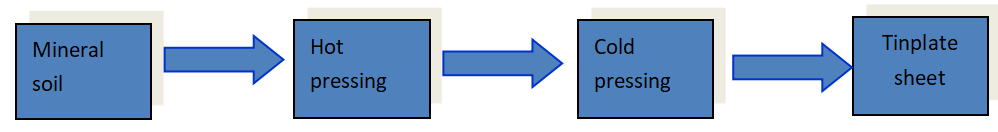

Paint tin can tinplate raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of tinpate sheet can be extracted from 1.8 ton of iron ore

Our advantage of tin cans with lids:

1). Our product quality is strictly guaranteed!

2). We can provide best service!

3). Our price is competitive!

4). We can do good payment terms.

Production process of small tins with lids:

In today's life, tin cans are an inseparable part of our lives. Gift tins, moon cake tins, tobacco and wine tins, cosmetics, food, daily necessities and other high-grade ones will also be packed in tin can and tin box. The following details the manufacturing process of paint tin cans:

1. overall design

The design of any product, especially packaging products, is its soul. Any packaging product must not only protect the packaged content to the greatest extent, but also must be sufficiently attractive to customers in appearance, so the design is particularly important. Design drawings can be provided by customers, or can manufacturers can design according to customer requirements.

2. prepare tinplate

Generally, the production materials of paint tin cans are tinplate, that is, tin-plated sheet steel. The content and specifications of tin-plated materials should meet the quality requirements of "National Tin-plated Sheet Steel" (GB2520). Generally, after the order is confirmed, the most suitable iron material, iron material type, size, etc. will be ordered according to the near-type layout. The iron material is usually stored directly in the printing plant. For the identification of the iron material quality, the visual inspection method can be used to see the surface Whether there are scratch marks, whether the texture is uniform, whether there are rust spots, etc., the thickness can be measured with a micrometer, and the hardness can be felt with a hand.

3. proofing

The mold room makes the product mold according to the design drawing, and the production department tests the mold to produce samples. If the mold fails, continue to repair the mold until the sample is correct before mass production.

4. typographic printing

It should be specifically explained here that the printing of iron materials is different from other packaging printing. It is not cut first and then printed, but printed first and then cut. Both the film and the layout are printed for the printing house. The printing house usually provides a template for the printing house to follow the color. In the printing process, it is important to pay attention to whether the printing color palette can keep up with the template, whether the positioning is accurate, and Stain, whether there are scars, etc. The printers generally responsible for these problems can control it themselves. There are also some canneries with their own printing plants or printing equipment.

5. iron cutting

The printed iron material can be cut on a cutting lathe. In the process of making a can, cutting is a relatively simple process.

6. stamping: that is, the iron material is pressed and formed on a punch. This is the most important part of can making. Usually a can can be divided into multiple processes to complete.

1). The general process of a two-piece can with a lid of heaven and earth is: lid: open material-flashing-winding line. Bottom cover: open material-flashing-pre-rolling line-winding line.

2). The process of closing the bottom and closing the bottom (sealing) of the tank, the lid: opening material-flashing-winding the can body: opening material-pre-bending-cutting angle-forming-button bone-punching body (button bottom)-back cover . The bottom process is: opening the material.

3). In addition, if the tin can is hinged, then the lid and the body each have one additional process: the hinge.

In the stamping process, the iron material is usually the largest. Pay attention to whether the work operation is standard, whether the surface of the product is scratched, whether there are batches of seams in the winding line, and whether the button joints are fastened. Arranging the confirmation of large-scale production samples and producing according to the confirmed large-scale samples can reduce a lot of trouble.

7. packaging:

After the stamping is completed, the closing step is entered. The packaging department is responsible for cleaning and assembling, putting in plastic bags and packing. This part is the finishing work of the product. The cleaning of the product is very important. Therefore, it is necessary to do the cleaning work before packaging, and then pack according to the packaging method. The products with many styles must be placed with the model number and box number correctly. What should be paid attention to during the packaging process is the quality control, which can reduce the inflow of defective products into the finished product, and the packing quantity must be accurate.