Specification of Printed Tins Round Tea Tin Box:

Product name | Printed Tins Round Tea Tin Box |

Description | A good packaging is the best and most cost-effective advertisement for your products such as candy, nut, cookie,chocolate and more. The metal container we produced is your best choice for its high quality and competitive price . |

Specifications | Product size: large,mini,any size is accepted Material: 0.20~0.28mm thickness tinplate for your choice design:Welcome your own design , we will protect your copyright if you have the legal copyright. Features : Recycle and durable ,eco-friendly, offset printing with good safety ink Three-piece structure ( lid, body and base) Hinged lid Vivid picture embossing on tin body Height is adjustable |

Printing | CMYK printing on outside of whole tin cans transparent varnish for inside tin it can be different according to your request |

Features | Recycle and durable eco-friendly offset printing with good safety ink |

Surface | Varnish / matt, Embossing and debossing is acceptable |

Competitive price : | competitive price for our customers to keep a long good relationships with each others |

Certificate | ISO 9001 |

Leadtime | 7-10 days for pre-production samples 25-30 days for mass production after sample approval |

Payment | 30% in advance,70% upon shipment |

Features of custom tea tins:

Food grade material for coating and varnishing.

Multiple printing processes.

2000 sets of moulds are available.

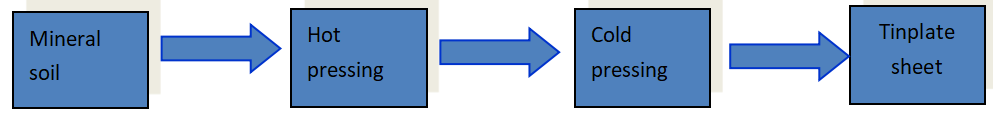

Tin box tinplate raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of tinpate sheet can be extracted from 1.8 ton of iron ore

Application of tins for tea storage:

1. Food cans

Tinplate can ensure the hygiene of food, minimize the possibility of corruption, effectively prevent health risks, and also meet the canned food packaged by modern people in tinplate.

The need for fast and convenient diet is the first choice for food packaging containers such as tea packaging, coffee packaging, health product packaging, candy packaging, cigarette packaging, gift packaging, etc.

2. Beverage cans

Tinplate cans can be used to fill juice, coffee, tea and sports drinks, and can also be filled with cola, soft drinks, beer and other beverages. And the high workability of tinplate cans makes the can shape change a lot, no matter whether it is tall, short, large, small, or square, or round, it can meet the diversified needs of today's beverage packaging and consumer preferences.

3. Grease cans

Light can trigger and accelerate the oxidation reaction of oils and fats, reduce nutritional value, and may produce harmful substances. More serious is the destruction of oily vitamins, especially vitamin D and vitamin A. The oxygen in the air promotes the oxidation of food fats, reduces the biomass of proteins, and destroys vitamins. The tint opacity and the effect of sealing the air are the best choices for packaging fat foods.

4. Chemical cans

Tinplate is sturdy, has good protection, does not deform, is shock-resistant, and fire-resistant. It is the best packaging material for chemicals.

5. spray cans

Tinplate cans that can withstand high temperatures and pressures, especially suitable for high-pressure filling spray cans.

6. Dry miscellaneous cans

Varying cans and beautifully printed biscuit barrels, stationery boxes, and milk powder cans are all tinplate products