Specification of Tin Plate Coated Blue For Printing paint Tins:

Product name | Tin Plate Coated Blue For Printing paint Tins |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA(Batch annealing),CA(Continuous annealing) |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.20~0.38mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

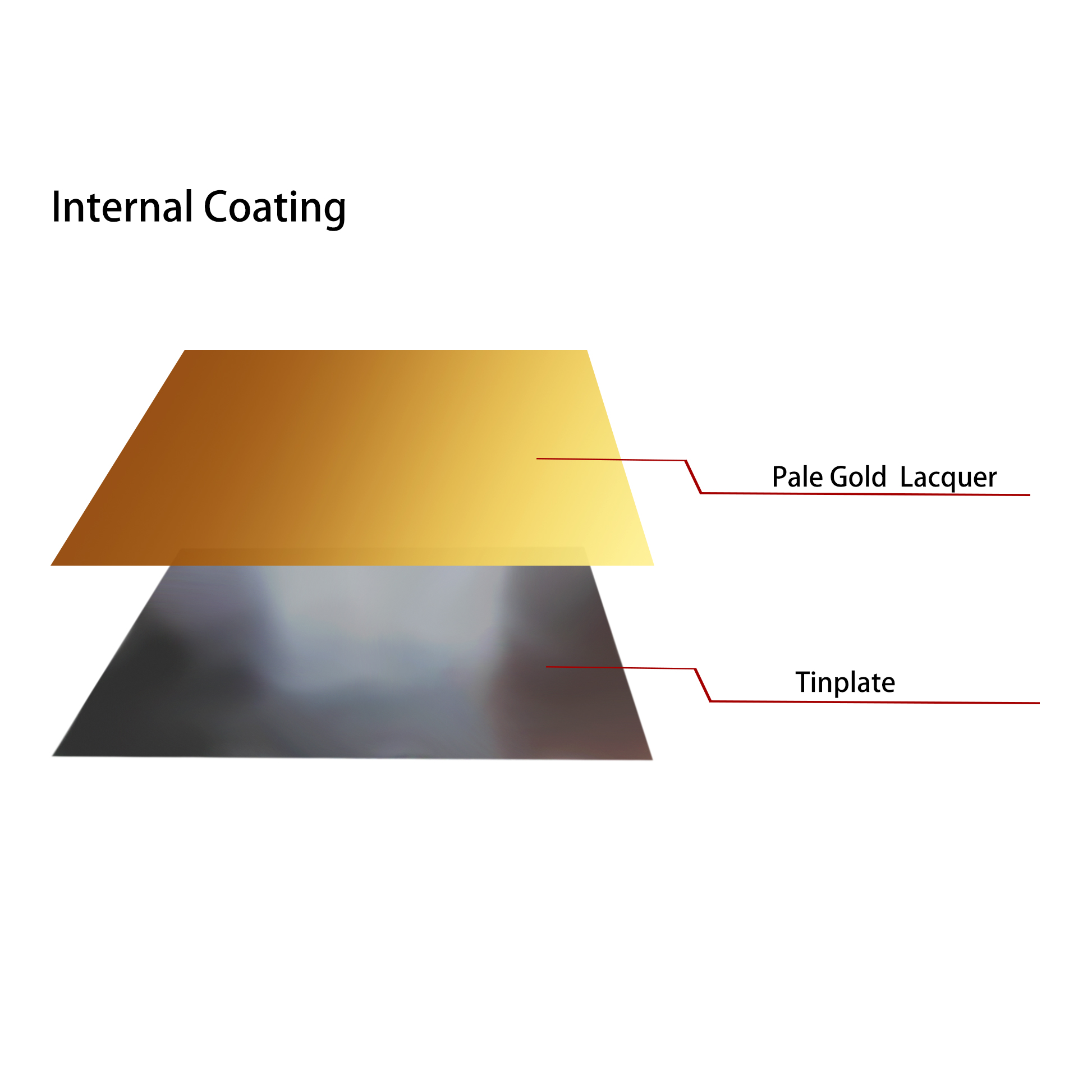

Internal coating | Transparency lacquer |

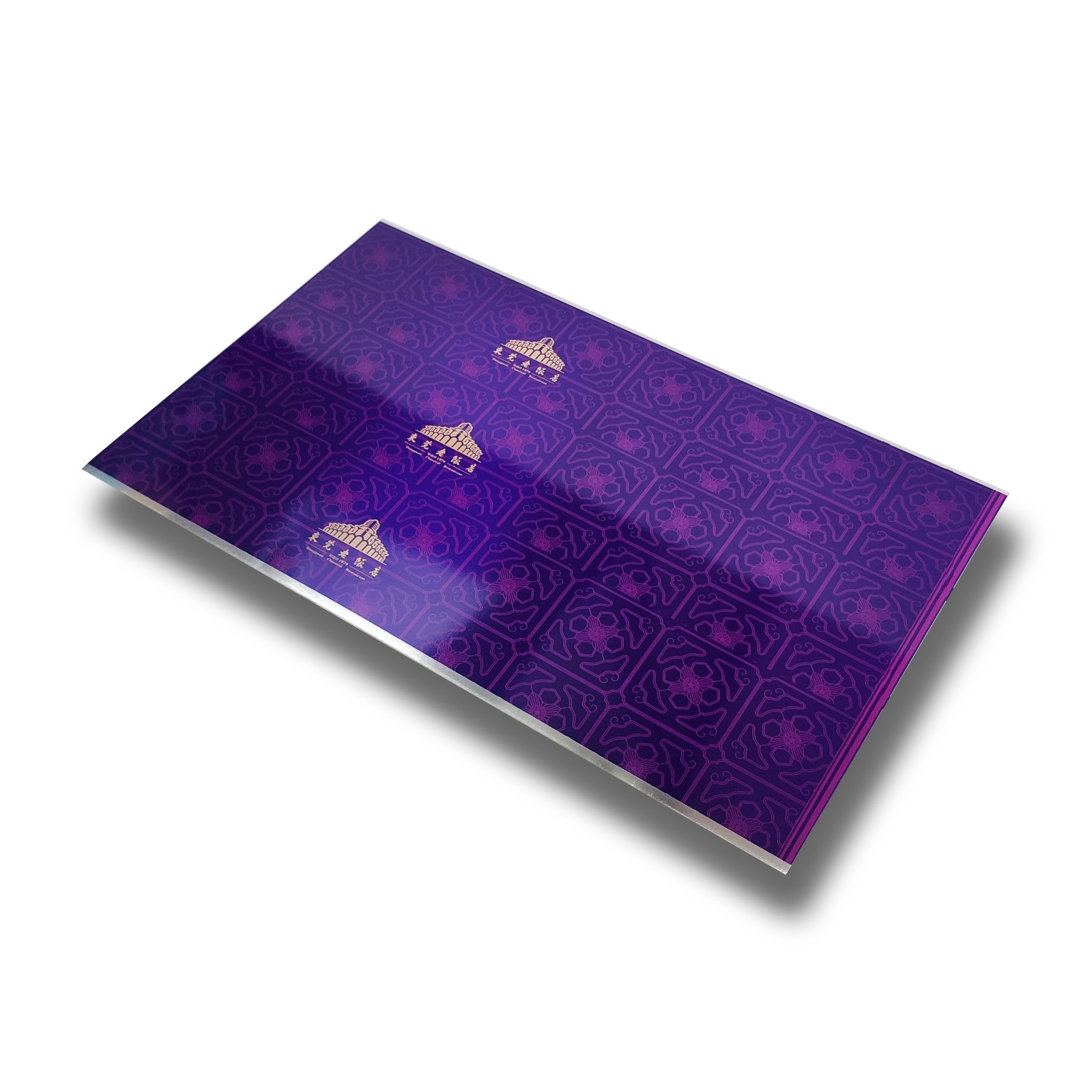

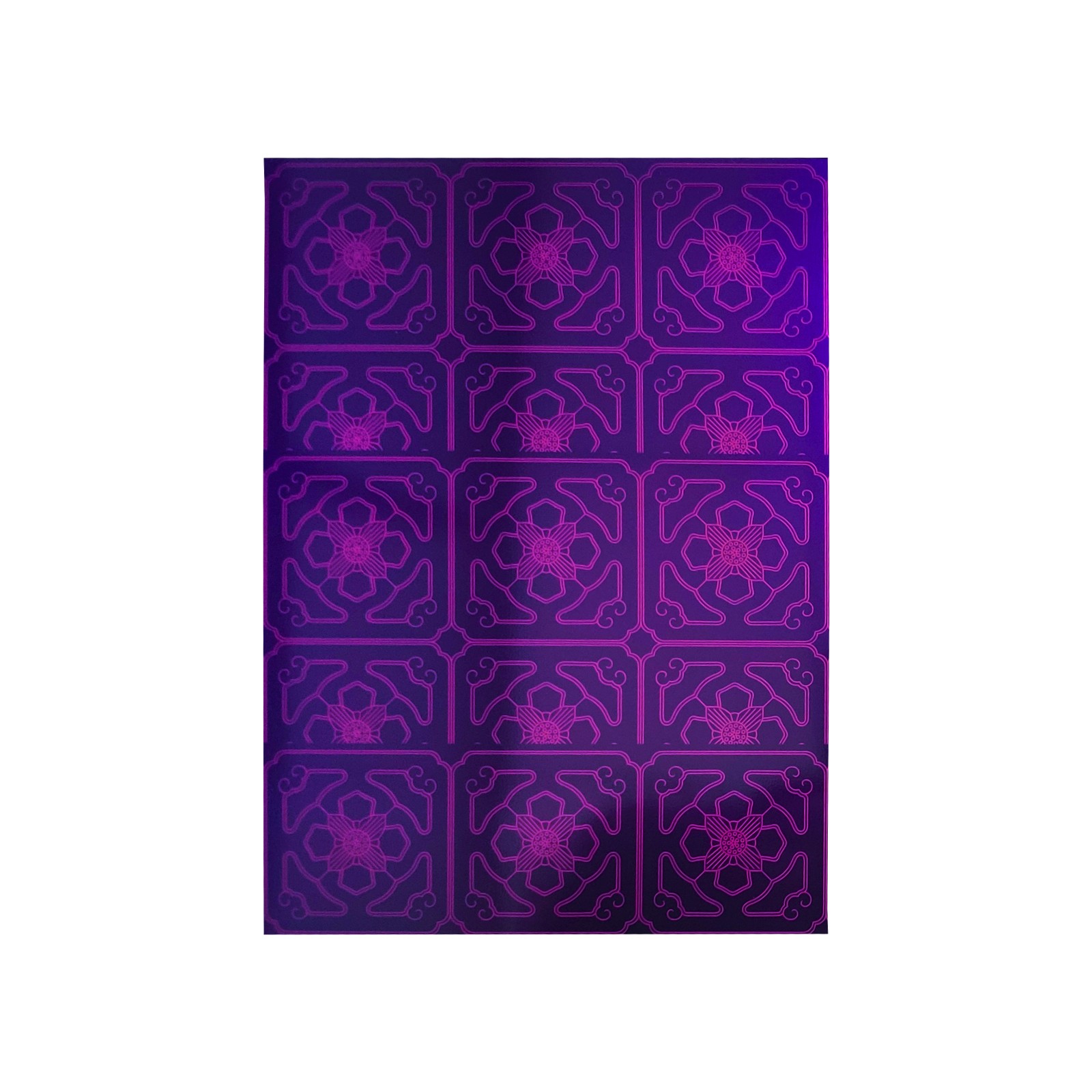

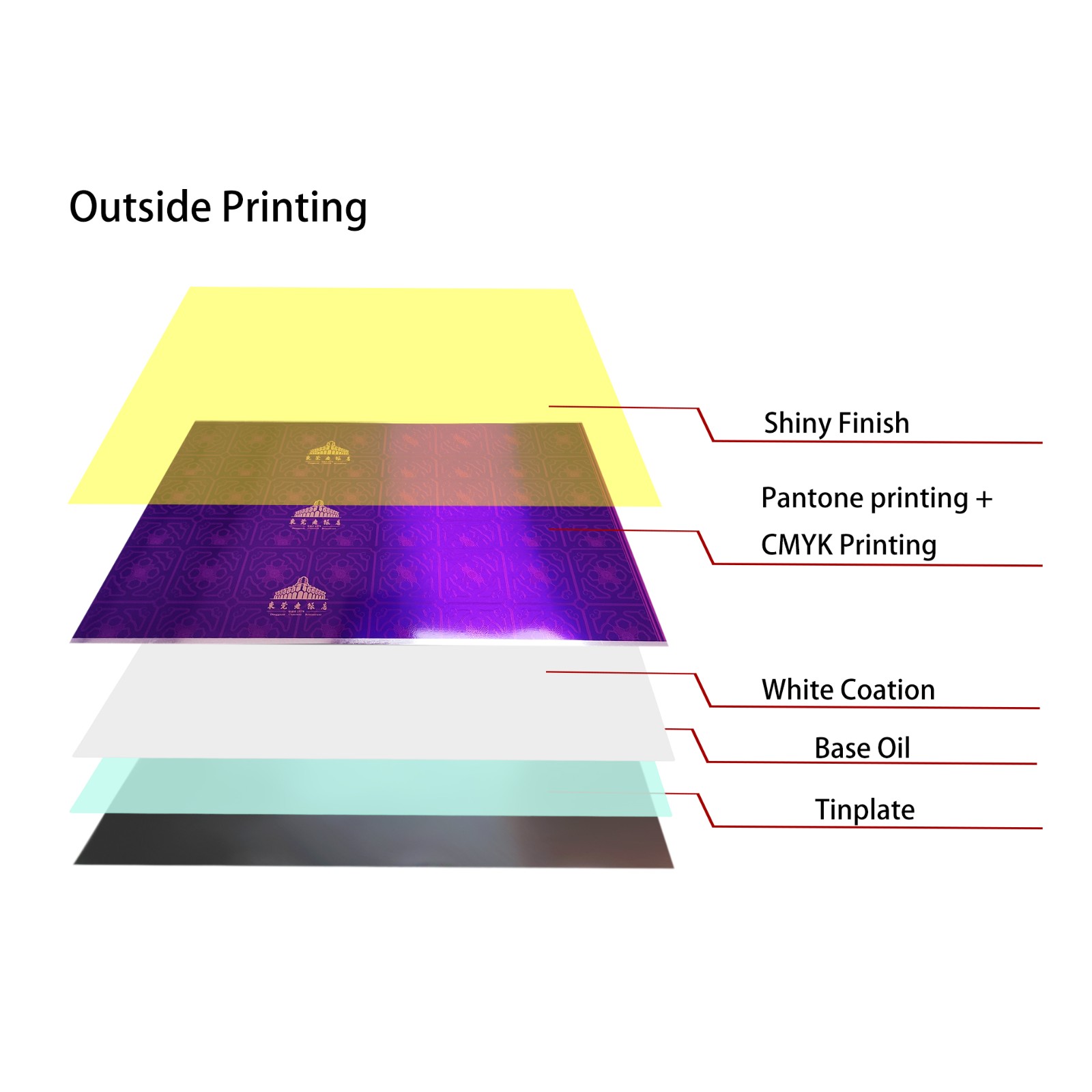

Outside coating | white+blule coation+CMYK printing+Shiny finish |

Application | For any packing Tin, Box, Can, Bucket, etc(Food, oil, paint, cosmetics, perfume,toys, chemicals, empty paint can, can of paint etc.) |

MOQ | 2 tons for each size |

Printing capacity | 5000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

Printed Tinplate

Tin Plate For Paint Tins

Printing Detail

Outside Printing

Internal Printing

All of our products support customization, if you need please feel free to contact us.

Sizes available for tin plate:

Type | Normal Thickness | Normal Width | Normal Length | Weight | Coil Internal Diameter |

Sheet | 0.15~0.45mm | 508~960mm | 712~1145mm | 1~1.5ton | ------ |

Coil | 0.15~0.45mm | 508~960mm | 712~1145mm | 3~10ton | 410/508mm |

Standard for Tinp late Temper:

Standard Material | Q/BQB 455-2009 | JIS G3315-2008 | ASTM A623M-08 | EM 10202:1989 | EN 1020:2001 | ISO 11950:1995 |

Single Reduce | - | T-1 | T-1(49) | T50 | TS230 | TH50+CE |

T-1.5 | - | - | - | - | - | |

T-2 | T-2 | T-2(T53) | T52 | TS245 | TH52+CE | |

T-2.5 | T-2.5 | - | - | TS260 | TH55+CE | |

T-3 | T-3 | T-3(T57) | T57 | TS275 | TH57+CE | |

T-3.5 | - | - | - | TS290 | - | |

T-4 | T-4 | T-4(T61) | T61 | TH415 | TH61+CE | |

T-5 | T-5 | T-5(T65) | T65 | TH435 | TH65+CE | |

Double Reduce | DR-7M | - | DR-7.5 | - | TH520 | - |

DR-8 | LR-8 | DR-8 | DR550 | TH550 | TH550+CE | |

DR-8M | - | DR-8.5 | - | TH580 | TH580+CE | |

DR-9 | DR-9 | DR-9 | DR620 | TH620 | TH620+CE | |

DR-9M | DR-9M | DR-9.5 | DR-660 | - | TH660+CE | |

DR-10 | DR-10 | - | - | - | TH690+CE |

Surface Finish on coated and printed tin plate:

Marks | Suface state | Characteristics | |

Single Reduce | B | Bright Surface | Glazed surface obtained a thin layer of chromium and chromium oxide which deposits on the smooth. |

Double Reduce | R | Stone Surface | Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone figures. |

S | Silver Surface | Glazed surface obtained after melting treatment of electronicned raw material strip with rough matt surface. | |

M | Matte Surface | Matte Surface | |

R | Stone Surface | Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone figures. |

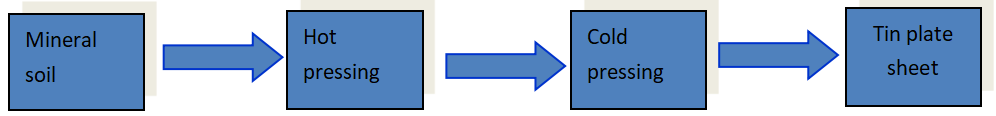

Tin plate sheet raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of tinpate sheet can be extracted from 1.8 ton of iron ore

Application of tin plate:

The coated and printed tinplate can be made into boxes, cans, barrels and other containers of various specifications by welding, sealing or stamping. Is widely used in food, tea, cosmetics, health products, medicine, gifts and other fields.