One of the primary intents of coating paint on the inner wall of food cans is to avoid a large amount of dissolution of tin. However, some foods require some tin in the tank to dissolve, forming free tin ions to maintain the appearance and flavor of the food in the tank. Without free tin ions, the color of light-colored foods tends to be dark, and the color of green vegetables will change. In the state of lack of oxygen in the can, tin ions and food form tin-chromium compounds to remove sulfides in the food. These effects will allow the canned food to be stored, sold, and eaten for a long time.

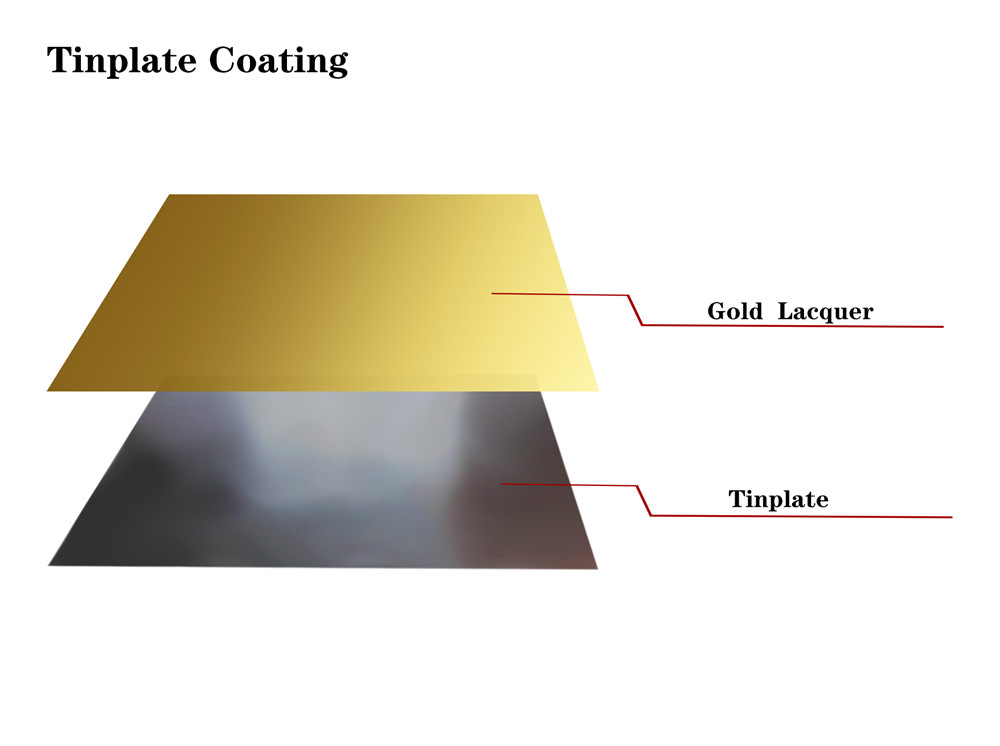

Tin can is dissolved in canned food, so the thickness of the coating on the inner wall of the can is generally between 3.5 and 6.0 g / m2. Within this thickness range, the coating has a certain porosity. The liquid in the can contents penetrates the surface of the tin layer through these pores, slowly dissolves the tin to form tin ions, and then reaches the intention of extending the shelf life of the can.

For acid foods, such as asparagus, bamboo shoots in clear water, broccoli, etc., the coating on the inner wall of the can can be printed using the "composite coating layer" process. These plants have a high protein content. In the process of canning and canning, the sulfur-containing amino saddle decomposes more hydrogen sulfide and has a strong sulfuric acid corrosion on the tank wall. The "composite coating layer" is the method of "three coatings and two baking" in the printing process. That is, a layer of primer with strong adhesion and plasticity based on epoxy resin and xylene resin is printed on the outer surface of tinplate. After baking and curing, the epoxy resin and phenolic resin-type paint are overcoated twice. (The bottom and lid of the tin can be turned on immediately after the second coating.) After the "three coatings and two bakings" printing, the total thickness of the coating reaches 10-13 g / m2, which increases the denseness of the coating and the porosity simply disappears. The coating not only has excellent adhesion, but also has good flexibility and ductility, and has outstanding can-making function.