Tinplate sheets printing and packaging are generally not easy to rust. The inside of the tin box is damp or placed in a damp place. It is easy to rust, and it is only when the outer coating is damaged that rust will appear. The material of the tinplate coil steel box is tin-plated thin steel plate. Due to the different metallic properties of iron and tin, the two metals are prone to oxidation reaction under natural conditions, causing the iron sheet to corrode and rust.

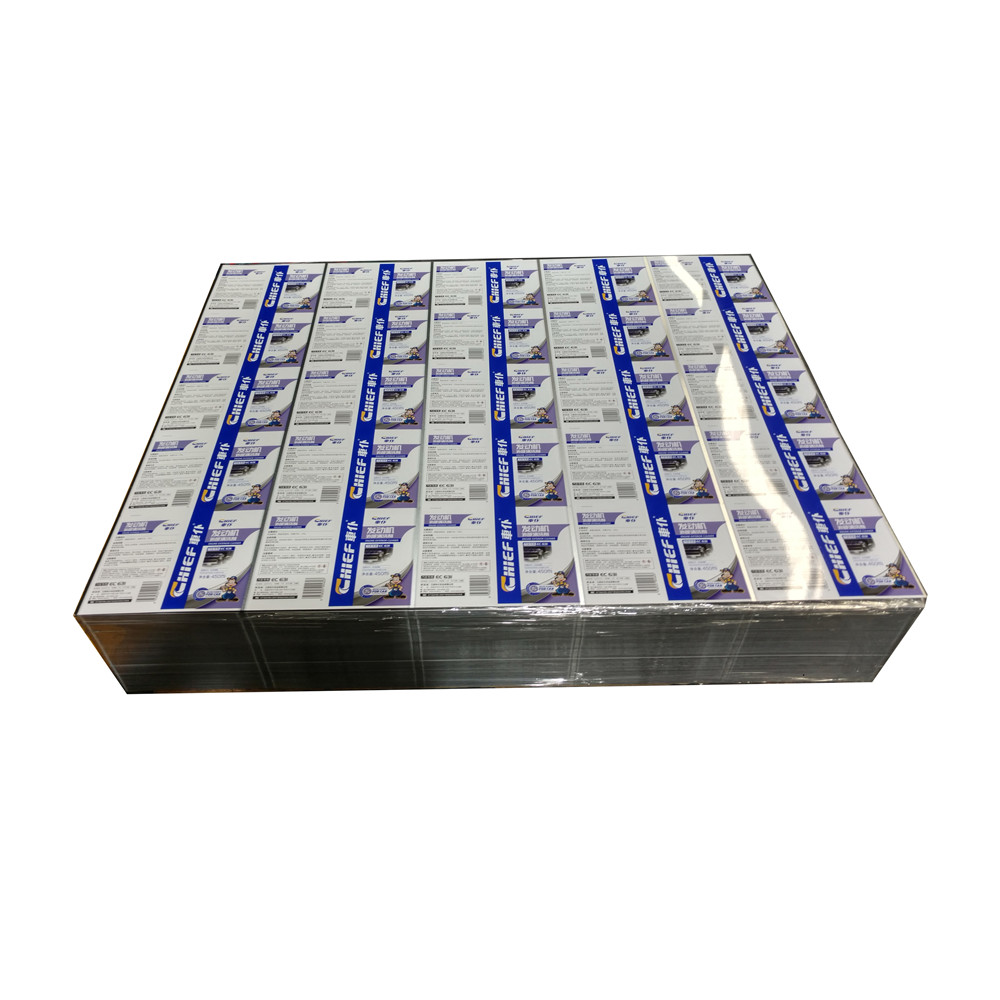

And for the finished tin box packaging, there is basically no need to worry about this problem, because before the tin box is formed, the plain tinplate sheets will be treated with rust. One is tinplate sheets printing and varnishing, which not only beautifies the tin box, but also uses the printing ink and the varnish on the surface have been double-layered to protect the iron material; the other is a plain tinplate sheets box, and the varnish is directly applied without printing. Both of these methods effectively isolate the iron material from contact with moisture in the air, and slow down the oxidation rate of the iron material.

In order to prevent tinplate sheets printing and packaging from the rusty "destiny", we should not place the tin box in a humid environment, and at the same time, handle the tin box gently to avoid damaging the paint printing on the surface of the tinplate sheets box, and then use the furniture in the home. Wipe the iron box with wax, shoe polish, floor wax, and repeat at intervals. You can also apply anti-rust paint or metal curing agent once on the surface of the iron box, which can effectively avoid direct contact between the tinplate and the air.