In recent years, people's attention to packaging materials has gradually shifted from traditional functionality to its environmental friendliness. Many consumers and companies have begun to pay attention to whether the packaging materials used are biodegradable and their impact on the environment. As a common metal packaging material, tinplate sheet is widely used in many fields such as food, beverages, cosmetics and chemical products.

However, many people may not know the question of "whether tin plate sheet is biodegradable". Therefore, this article will discuss the degradation performance of tinplate sheet and deeply analyze its biodegradation process and related factors.

What is tinplate sheet?

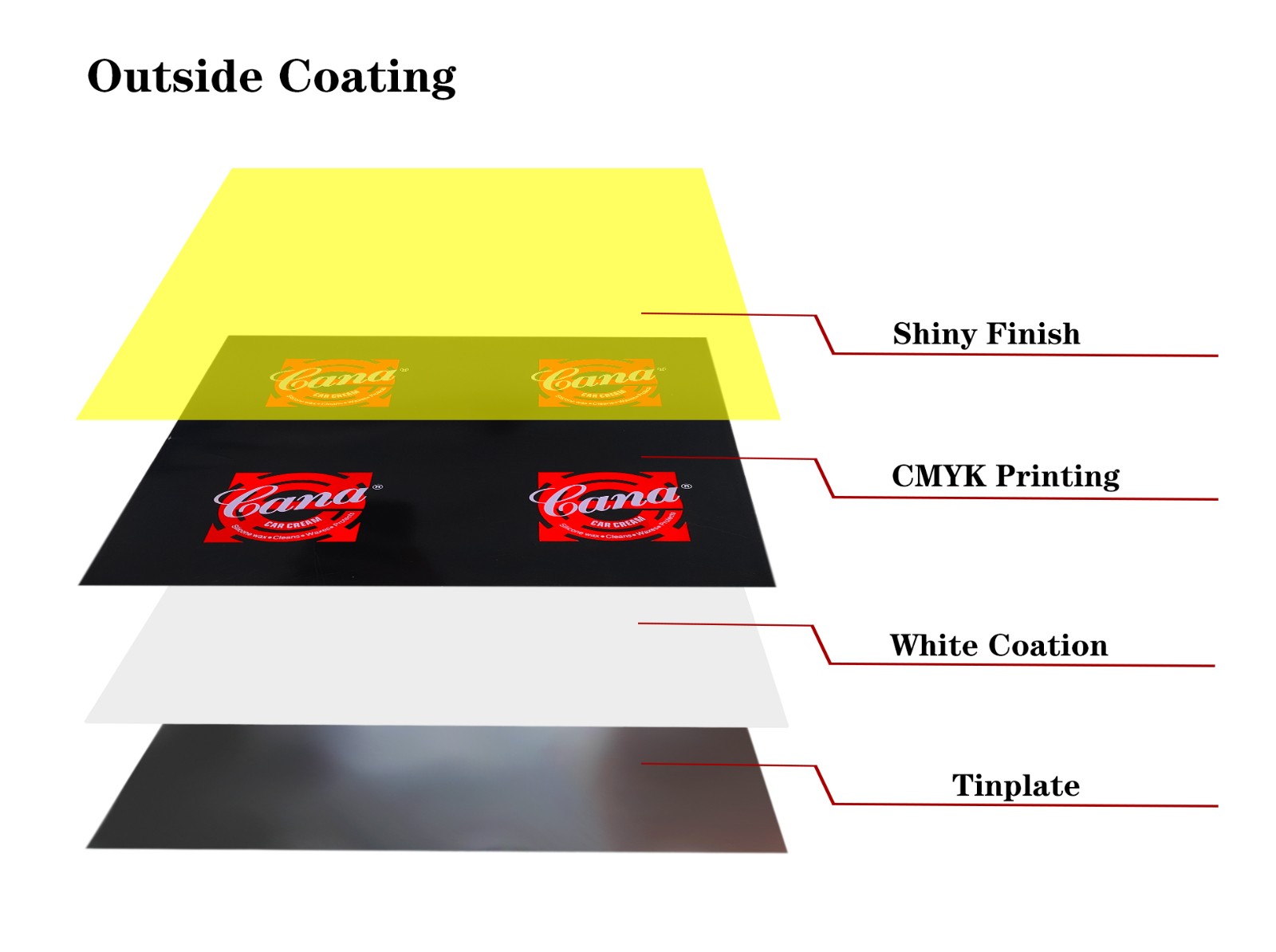

Tin plate sheet, as a widely used packaging material, is mainly made of low-carbon steel or iron, with a layer of tin (Sn) on the surface. This material has excellent anti-corrosion properties, strength and plasticity, and is widely used in food cans, beverage cans, chemical containers, paint buckets and many other industrial products. The core component of tin plate sheet is steel, and the outer tin coating plays a role in preventing the internal steel from rusting.

However, the chemical composition and physical properties of tinplate sheet make it different from many other biodegradable materials such as paper, natural fibers or certain plastics. Before we can understand whether tinplate sheet is biodegradable, we first need to understand what "biodegradation" means.

What is biodegradation?

Biodegradation is the chemical and physical decomposition of organic materials by microorganisms (such as bacteria, fungi or other organisms) into carbon dioxide, water, biomass or inorganic compounds. The biodegradation process usually occurs in the natural environment, especially in the presence of oxygen (aerobic decomposition) or in the absence of oxygen (anaerobic decomposition).

Common biodegradable materials include paper, certain types of plastics (such as polylactic acid, PLA), wood, plant fibers, etc. However, metal materials such as steel, aluminum, tin, etc. do not directly participate in the typical biodegradation process due to their different structures and chemical properties. Instead, they undergo different physical and chemical degradation processes such as oxidation and corrosion in the natural environment.

Is tinplate sheet biodegradable?

According to the definition of biodegradation, tin plate sheet cannot be classified as a biodegradable material. Biodegradation usually applies to organic matter or certain special bio-based materials, while tinplate sheet, as a metal composite material, will not degrade into carbon dioxide or water through the metabolic process of microorganisms under natural conditions.

However, although tinplate sheet is not a biodegradable material, it can still degrade in the environment, but this degradation is mainly achieved through physical and chemical effects. The degradation process of metal materials often manifests itself as chemical reactions such as corrosion and oxidation, rather than biodegradation. Therefore, although tinplate sheet cannot be considered a biodegradable material in the strict sense, its corrosion and decomposition phenomenon in the natural environment deserves further discussion.

Although tin plate sheet steel still takes a long time to decompose, it decomposes much faster than plastic. Plastics also tend to end up in the ocean, causing various problems for marine life. In fact, plastics account for 80% of the waste that ends up in the ocean. In contrast, although tin plate sheet steel takes longer to decompose, it will eventually degrade into reusable materials and have less impact on the environment.

What is the degradation process of tinplate sheet?

Although tinplate sheet cannot be decomposed through biodegradation like paper or organic plastics, it can still undergo a more complex degradation process in the environment. This process mainly involves two aspects: the change of the tin layer and the oxidation of the internal steel substrate.

Corrosion and degradation of the tin layer

The tin-plated layer on the surface of the tin plate sheet is its main barrier to corrosion. Tin is a relatively stable metal that can well protect the iron substrate from oxidation. However, under certain conditions, tin will also undergo oxidation reactions, especially in the presence of moisture, oxygen, and acidic or alkaline substances. The oxidation of tin is mainly manifested in the following situations:

● Oxidation reaction: When tin is exposed to air, it reacts with oxygen to form tin oxide (SnO or SnO₂). This oxidation process is not as rapid as the oxidation of iron, but after long-term exposure to a humid environment, the surface of the tin layer will gradually lose its luster, become rough, and oxide deposits will appear.

● Electrochemical corrosion: When the tin plate sheet is in a humid environment, especially in an environment containing electrolytes (such as salt water or acidic solutions), electrochemical corrosion will occur between tin and iron. Tin is used as the cathode material and iron is used as the anode. Under the action of the electrolyte, the iron will corrode first. This corrosion process will cause local peeling of the tin layer, exposing the steel substrate, further accelerating the oxidation process of the iron.

Oxidation and corrosion of iron substrate

Once the tin layer is damaged or corroded, the internal iron substrate will be directly exposed to air and moisture, resulting in increased oxidation and corrosion. The oxidation reaction of iron is a very common process, usually manifested as rust. After iron comes into contact with oxygen and water in the air, the following chemical reaction occurs: 4Fe+3O+6HO→4Fe(OH)

This process forms iron hydroxide (Fe(OH)₃), which is common rust. Rust not only affects the appearance and structure of tin plate sheet, but also further accelerates its degradation. Over time, rust will continue to spread, causing the physical structure of tinplate sheet to gradually decompose.

● Factors affecting corrosion rate: The oxidation and corrosion rate of iron depends on multiple factors, including ambient humidity, oxygen content, temperature, and the concentration of surrounding electrolytes (such as salt water or acidic substances). In humid, acidic or high-salt environments, the corrosion rate of iron will increase significantly, which is why tin plate sheet is more susceptible to corrosion in marine environments or acidic soils.

Final degradation products

The degradation products of tin plate sheet in the natural environment are mainly tin oxide, iron oxide (rust) and some metal ions. These products are usually deposited in the soil or water in solid form and gradually mixed with other minerals in the environment. Compared with some organic materials, metal oxides have relatively less direct pollution to the environment, but their degradation process is very slow.

For example, it takes decades or even longer for rust to further degrade under natural conditions, while metal oxides such as tin oxide are more stable in the environment and difficult to decompose further. Therefore, although tin plate sheet can be degraded by corrosion and oxidation, this process is very slow and the degradation products produced exist in the environment for a long time.

Is the degradation of tinplate sheet environmentally friendly?

Although tinplate sheet cannot be completely decomposed by biodegradation, whether its corrosion and degradation process in the environment is environmentally friendly depends on multiple factors. In general, the degradation of tinplate sheet has less impact on the environment than non-degradable materials such as plastics, but there are also some potential problems in its degradation process.

Metal pollution problem

Although the degradation products of tinplate sheet are mainly rust and tin oxides, which are not directly toxic to the environment, the release of metal ions may have a certain impact on the ecosystem in certain specific environments. Especially in acidic soils or water bodies, the corrosion products of tin plate sheet may release trace metal ions, which may have a negative impact on plant growth or aquatic organisms.

Resource waste during degradation

The natural degradation process of metal materials is usually accompanied by resource waste. Steel and tin are valuable resources that can be recycled and reused. If tinplate sheet products are discarded into the environment at will, it will not only accelerate the waste of metal materials, but also increase the degradation burden of the environment. Therefore, it is particularly important to recycle tin plate sheet more effectively and reduce its natural degradation process in the environment.

What is the relationship between the recycling and degradation of tinplate sheet?

Unlike materials such as plastics, tin plate sheet has a high recycling value. Steel and tin are both metal materials that can be recycled and reused many times. In fact, the recycling process of tinplate sheet is more environmentally friendly and economical than natural degradation, so modern society emphasizes the recycling of tinplate sheet rather than relying on its slow degradation process.

The recycling process of tin plate sheet is relatively simple: first it is separated from the waste by magnetic separation, then melted and reprocessed. In this process, steel and tin can be re-extracted and used to produce new metal products. This not only reduces metal pollution to the environment, but also greatly saves resource consumption.