Specification of 20 L Wood Paint Tin Printing Tinplate Container:

Product name | 20 L Wood Paint Tin Printing Tinplate Container |

Features | Eco-friendly and recyclable, durable and long lasting use |

Material | 0.20-0.38mm thickness first grade tinplate |

Size | Customized according to your requirements |

Color | Various colors for your selection, or customized color |

Printing | CMYK or PMS offset printing, with glossy or matt varnish |

Packing | Each in a polybag, several pcs in one carton, other safe packing is according to your requirement |

Certificate | ISO 9001 |

Sample | Free samples, express freight collect |

Customization | Customized size, shape, printing, embossing logo and 3D embossing are all welcome, artwork is accepted |

Main ProduAll of our products support customization, if you need please feel free to contact us.ct | packaging materials for food and beverages to grease cans, chemical cans,paint tin, and other miscellaneous cans

|

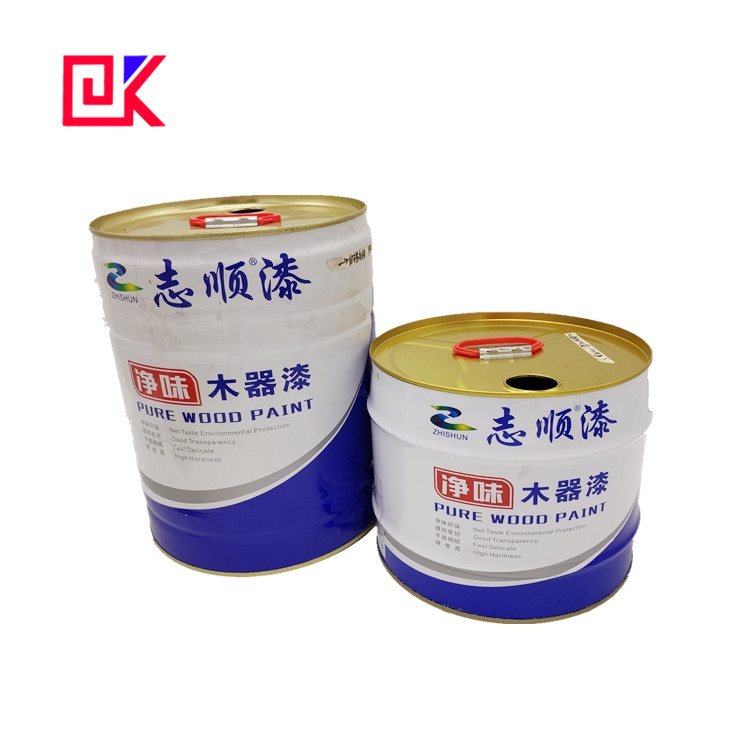

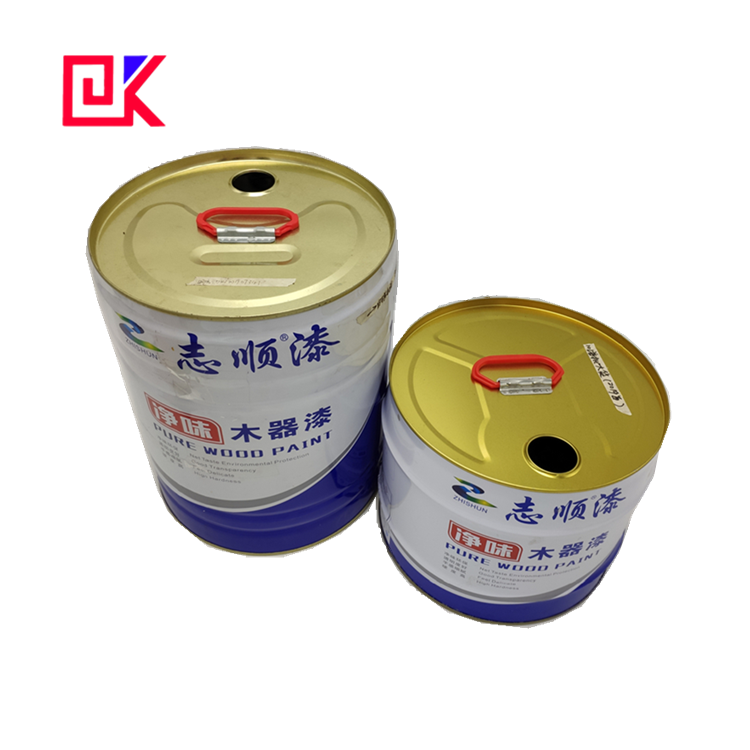

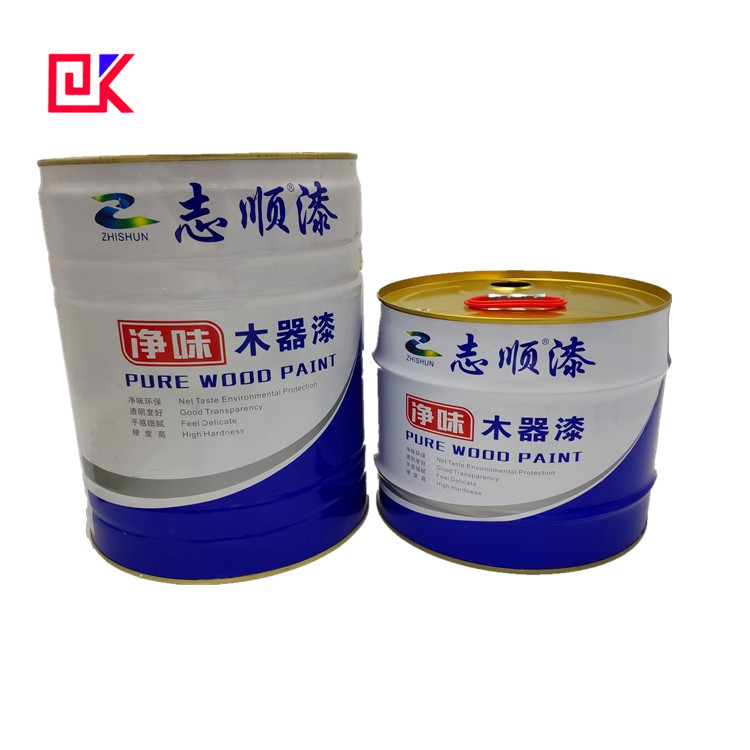

Product Show

Tin Can

Product Detail

All of our products support customization, if you need please feel free to contact us.

Metal paint cans with lids printing process:

The tinplate printing process is mainly divided into several major processes such as color separation, proofing, determining drawings, printing, determining printing materials, and coatings.

Color separation is an important part of printing metal products: At present, most of the domestic and foreign iron printing equipment is mainly two-color printing machines, mainly to ensure that the tinplate printing color effect meets the original effect provided by customers. In order to avoid inaccurate overprinting, scratching, obvious chromatic aberration, uncolored colors, and many defective products in multi-color printing, the spot color is used to replace multi-color overprinting, such as Pantone. At the same time, it is mainly based on back-to-back dots and thick screen lines to reduce the total number of dots in the total area. The smaller the number of dots to expand, the better the printing effect.

2. Iron proofing: It is mainly the inspection of color separation film and the pre-quality analysis and grasp of tinplate products. In the proofing process, it is necessary to leave color separation samples as a reference basis in the printing process control, so that the printing quality is stable and the colors can truly reproduce the samples confirmed by the customer.

3. Determine the drawing: The printed iron drawing must determine the three factors of the tinplate positioning rules, the product arrangement method, and the rubber roller used when the product is coated with paint. The tinplate positioning rules refer to the direction and size of the bite, leaning against the body, and are the basis for printing. The arrangement of the product is the basis of the printing process. The arrangement of the product is different. The arrangement of the tinplate needs to be considered in determining the arrangement. The smallest and largest sizes that can be accepted at the same time make the arrangement most economical.

4. Plate printing: For tinplate cans and lid printing, most of the same screens are made into negative or positive pictures according to the determined product drawings when making lithographic plates, and the plates are exposed using continuous exposure machines.

5. Determining the printing material: As the application and molding equipment of different products have different process requirements for the thickness, tin layer, hardness and annealing method of tinplate, we must determine the above factors according to the nature of the product. It must meet the printing requirements. In order to meet the requirements of can making and punching, and determine the final printing surface, Foshan Dekai Metal Packaging Co., Ltd. reminded that the general tinplate printing is to use the physical properties of water and ink to repel, and use printing pressure to pass the blanket The printing plate graphic text is transferred to the iron box, which belongs to the principle of lithographic offset printing.

6. Coatings: Iron printing is not the ultimate goal, but a means of beautification of metal packaging. The purpose is to make all kinds of metal containers, such as tinplate cans, various types of bottle caps, iron boxes, toys, etc. In order to make the pictures printed on the metal plate bright and eye-catching, the special role of the paint is inseparable. At the same time, the paint can increase the brightness of the tinplate pattern, so that the product has a metallic color and does not change color or paint off during the final molding process. Foshan Dekai Metal Packaging Co., Ltd. warmly reminds general manufacturers to use a layer of bright oil on the surface of the printing tin box to increase the gloss of the surface of the printed product, and also increase the hardness of the surface of the tinplate product, so that the printing The ink layer has a certain flexibility and corrosion resistance, so it can produce beautiful and eye-catching tin box printing packaging.

FAQ for empty paint cans with lids:

Q: What is tinplate?Are printed tin safe for food?

A: Tinplate is the steel electrolytically coated with a fine layer of tin for tin protective purposes.Tinplate is a high quality safe packaging material for food items.Such as cookies candies,chocolate,etc.A food grade lacquer is coated on the inside of the tin to prevent corrosion and interaction of the tin with the food product and thus make it suitable for food storage.

Q: What artwook file formats are acceptable?

A: The most popular acceptable software for artwork design is CDR and AI.PDF and PSD are also welcome.The resolution should be no less than 300 dpi.Please save your files on a CD and submit it to us by service and freight prepaid.

Q: What about the normal lead time?

A: Normally 3-7 working days for small order, and 15-30 days for big order.

Q: How do you control the quality?

A: Advanced machines and testing devices to make sure good quality.We will make samples before mass production,and after sample approved,we will begin mass production.

Q: How should I design on a tin?

A: Before designing any graphics on a particular tin,we will furnish a dimension layout for positioning graphics.According to the tin construction,this positioning info is very important to ensure the proper placement of artworks onto each of the tin.