Specification of Canned Food Tin Container Packaging:

Product name | Canned Food Tin Container Packaging |

Description | A good packaging is the best and most cost-effective advertisement for your products such as candy, nut, cookie,chocolate and more. The metal container we produced is your best choice for its high quality and competitive price . |

Specifications | Product size: large,mini,any size is accepted Material: 0.18~0.28mm thickness tinplate for your choice design:Welcome your own design , we will protect your copyright if you have the legal copyright. Features : Recycle and durable ,eco-friendly, offset printing with good safety ink Three-piece structure ( lid, body and base) Hinged lid Vivid picture embossing on tin body Height is adjustable |

Printing | CMYK printing on outside of whole tin cans transparent varnish for inside tin it can be different according to your request |

Features | Recycle and durable eco-friendly offset printing with good safety ink |

Surface | Varnish / matt, Embossing and debossing is acceptable |

Competitive price : | we are insist on competitive price for our customers to keep a long good relationships with each others |

Certificate | ISO 9001 |

Leadtime | 7-10 days for pre-production samples 25-30 days for mass production after sample approval |

Payment | 30% in advance,70% upon shipment |

Basic requirements for tin food containers packaging:

1. Security. As a food tin container, because it is in direct contact with food, the most important and most basic thing is that it is harmless to the human body and ensures that the food meets the health regulations of various countries. Canned food for export must generally comply with relevant sanitary standards of the FDA and the importing country.

2. Sealability, because food is usually spoiled due to microorganisms, the food tin container must have reliable sealability, so that after food is sterilized by heating, it can no longer be contaminated by external microorganisms.

3. Corrosion resistance. A large part of the food in the tin container has certain nutrients, organic acids and certain compounds, which will decompose during the high-temperature and high-pressure sterilization process. To ensure the long-term storage of food, the tin box selected must have good corrosion resistance.

4. Convenience. As a container for storing food, it must be convenient for consumers to carry and take food, and it must have the conditions for long-distance transportation.

5. It is suitable for industrial production. During the production process, the tin box must withstand various mechanical stamping, crimping, welding and other processes, and the demand is large and mass production is required. Therefore, it must have factory mechanized and automated production requirements. It must have high efficiency, stable quality, low cost, and meet the requirements of modern production management.

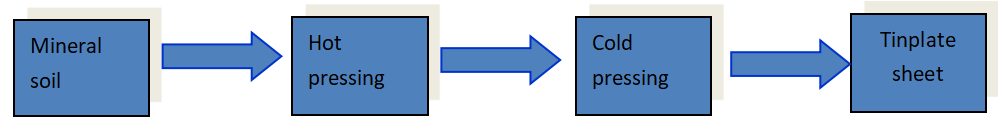

Tin container raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of tinpate sheet can be extracted from 1.8 ton of iron ore

Application:

1. Usually divided into moon cake cans, DVD tin cans, chocolate cans, iron tea cans, coffee cans, biscuit cans, health food cans, beauty cans, hand cans, savings cans, sealed cans, milk powder cans, wine cans , Christmas tins, gift tins, candle tins, metal buckets, badges, coasters, tinplate toys, music boxes, cigarette boxes, stationery boxes, CD boxes, cigarette boxes, all kinds of special-shaped can molds.

2. According to the shape classification, it is divided into round cans, rectangular cans, square cans, oval, heart-shaped and special-shaped cans (car shape / cartoon animal shape).

Production steps for empty tin cans:

1. Making artwork based on your CUSTOMIZED designs.

2. After you confirm artwork,will do FREE pre-production sample for you checking.

3. You can confirm by Photograph or by Physical check.

4. After you confirm sample,will start mass production