Specification of CMYK Printing Tinplate For chemical tin:

Product name | CMYK Printing Tinplate For chemical tin |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thicknes | 0.20~0.38mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

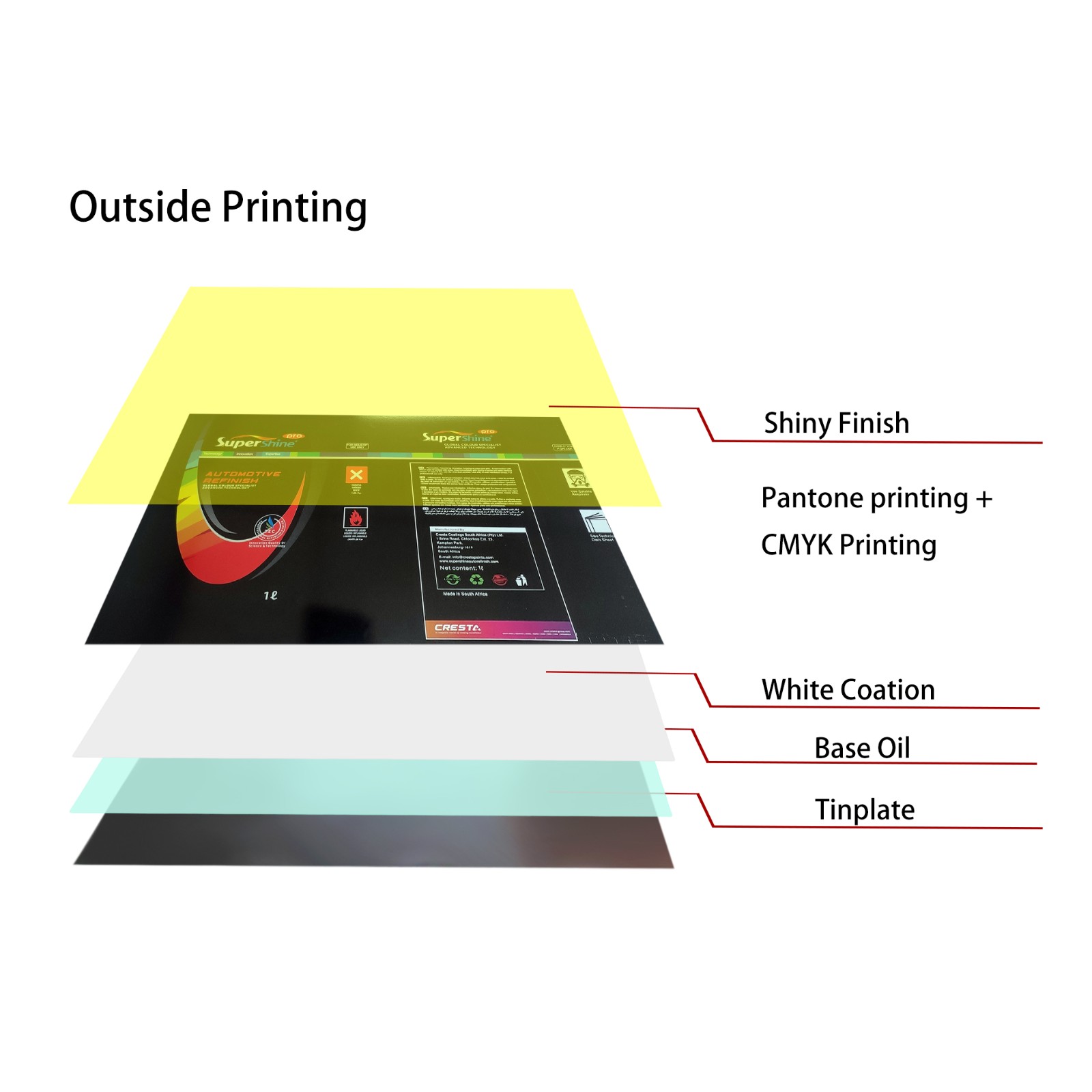

Internal coating | White coation or Gold lacquer |

Outside printing | White coation+CMYK Printing+transparency lacquer |

Application | For any packing Tin,Box, Can, Bucket, etc(Food, oil, medicines, cosmetics, perfume,toys, chemicals,chemical waste container, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

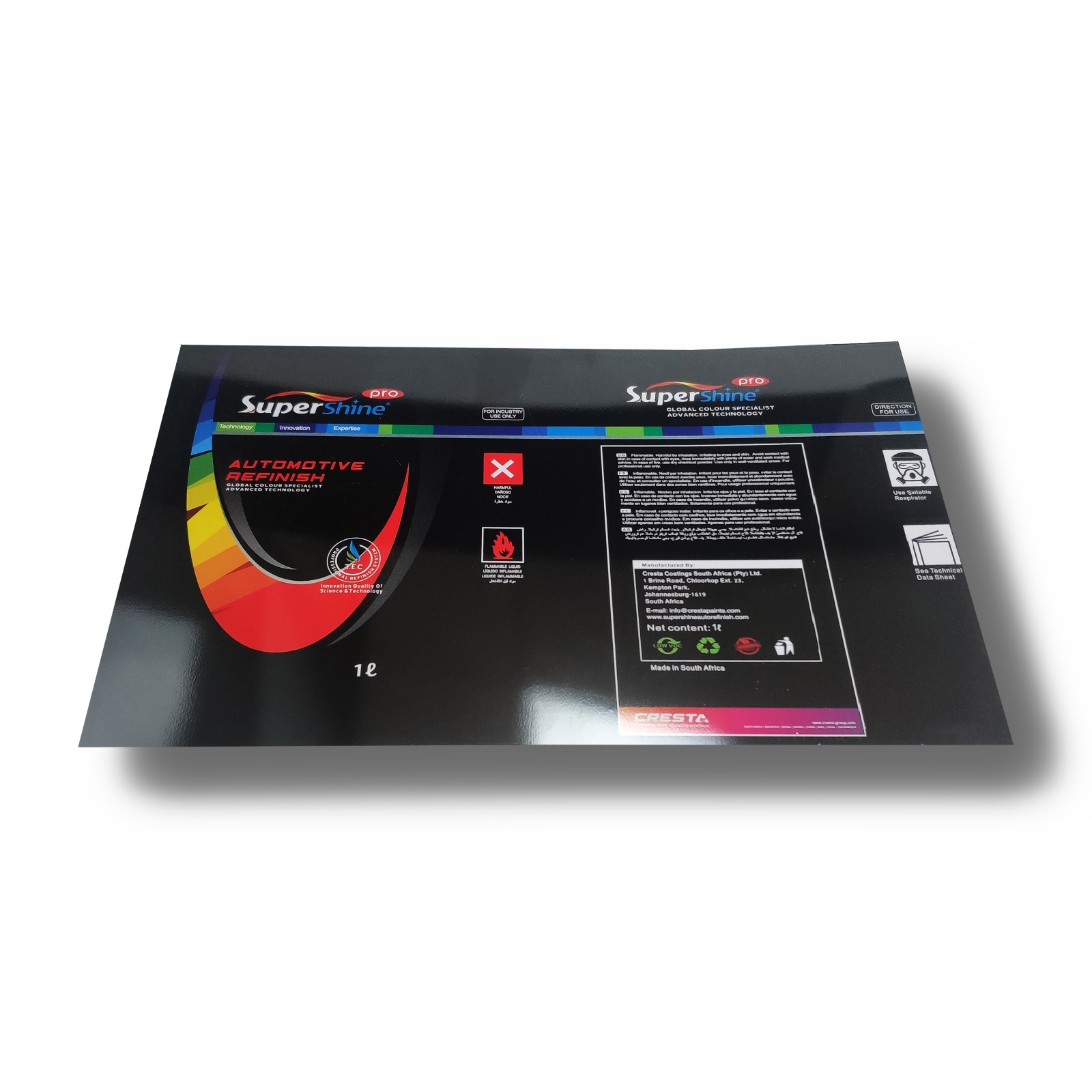

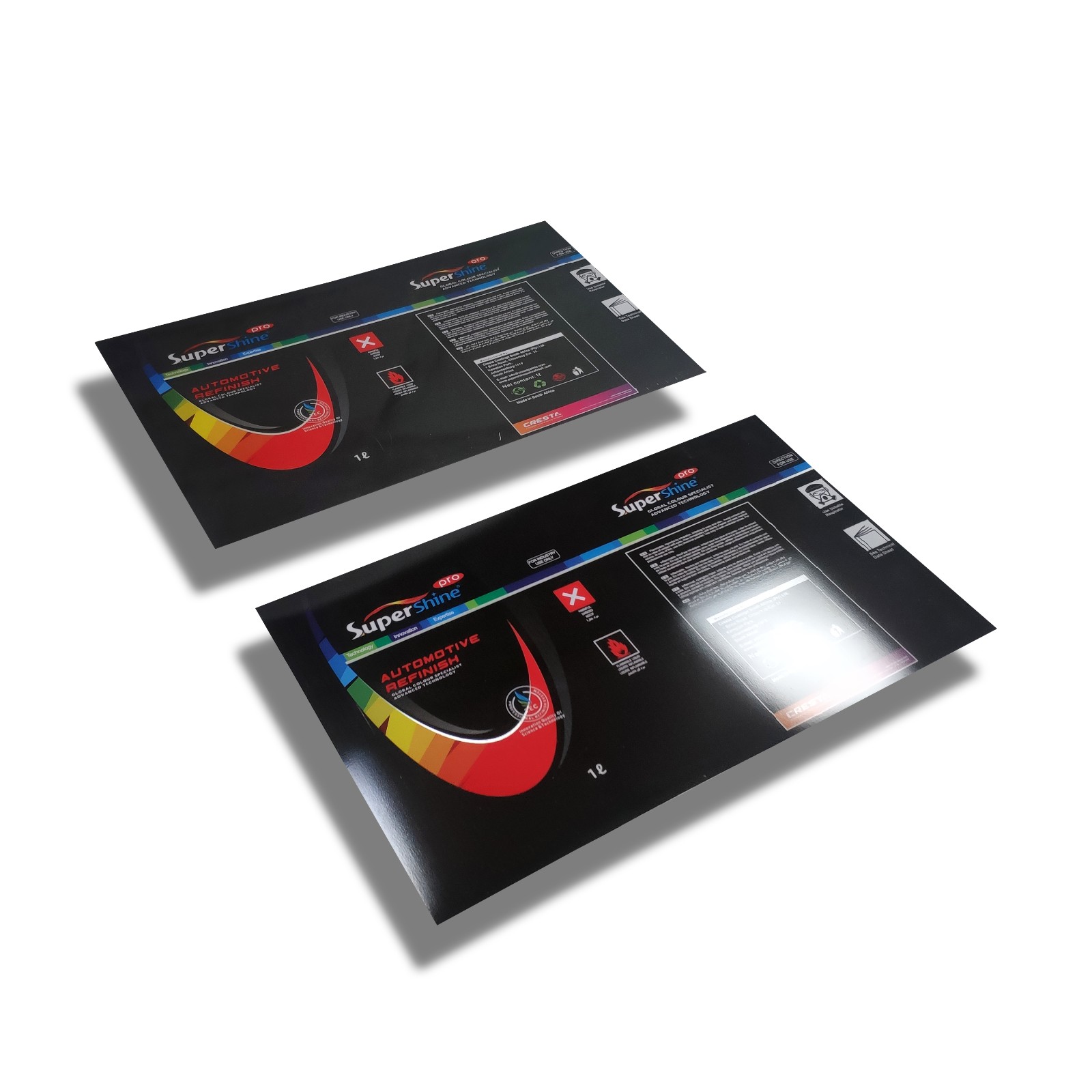

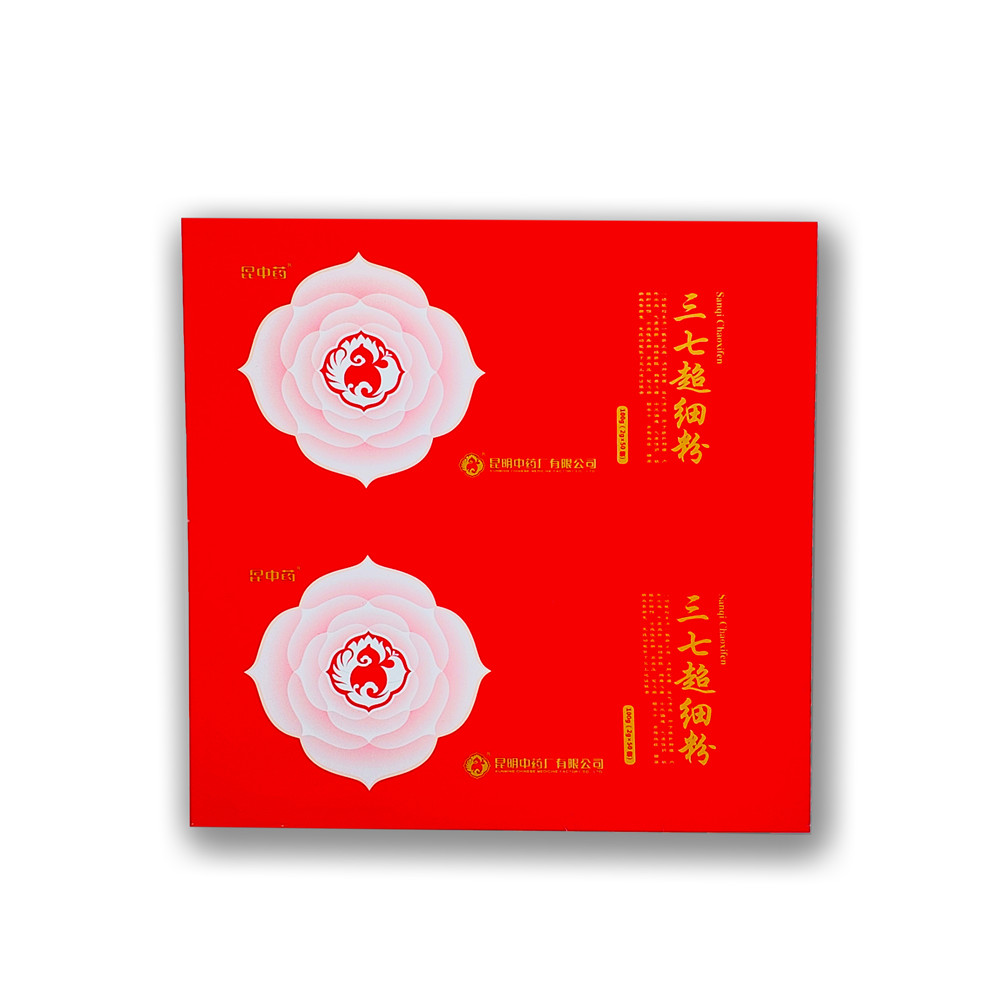

Product Design

Tinplate For chemical drum

Product Detail

Printing

Outside Printing

All of our products support customization, if you need please feel free to contact us.

Standard for tinplate temper:

Code | Chineses | Japaness | American | Europen | International |

GB/T2520-2000 | JIS G3303-2002 | ASTM | DIN EN | ISO | |

T-2 | TH52+SE | T-2 | T-2(T53) | T52 | TH52+SE |

T-2.5 | TH55+SE | T-2.5 | TH55+SE | ||

T-3 | TH57+SE | T-3 | T-3(T57) | T57 | TH57+SE |

T-3.5 | |||||

T-4 | TH61+SE | T-4 | T-4(T61) | T61 | TH61+SE |

Tin coating weight on tinplate:

Tinplate Status | Coating Status | Former Coat | Coating W. Code | Normal C-W | Min. Ave. C-W | Remarks |

EPT | Equally Coating (E) | 10# | 1.1/1.1 | 1.1/1.1 | 0.9/0.9 | All specifications |

20# | 2.2/2.2 | 2.2/2.2 | 1.8/1.8 | |||

25# | 2.8/2.8 | 2.8/2.8 | 2.5/2.5 | |||

50# | 5.6/5.6 | 5.6/5.6 | 5.2/5.2 | |||

75# | 8.4/8.4 | 8.4/8.4 | 7.8/7.8 | |||

100# | 11.2/11.2 | 11.2/11.2 | 10.1/10.1 | |||

Classified Coat (D/A) | 25#/10# | 2.8/1.1 | 2.8/1.1 | 2.5/0.9 | ||

50#/10# | 5.6/1.1 | 5.6/1.1 | 5.2/0.9 | |||

50#/25# | 5.6/2.8 | 5.6/2.8 | 5.2/2.5 | |||

75#/25# | 8.4/2.8 | 8.4/2.8 | 7.8/2.5 | |||

75#/50# | 8.4/5.6 | 8.4/5.6 | 7.8/5.2 | |||

100#/25# | 11.2/2.8 | 11.2/2.8 | 10.1/2.5 | |||

100#/50# | 11.2/5.6 | 11.2/5.6 | 10.1/5.2 | |||

100#/75# | 11.2/8.4 | 11.2/8.4 | 10.1/7.8 |

Application of tinplate printing:

tinplate printing products are widely used in different types of food, canned beverages, daily cosmetics, pharmaceuticals, and petrochemical products with their novel design and special exquisite printing effects And various packaging containers.

What is CMYK printing tinplate ?

Normal four-color printing: Refers to the printing process that uses the three primary colors of yellow, magenta and cyan and black ink to reproduce the colors of the color original. And because cyan and blue are similar, the four colors have a popular saying in many places: black, red, blue, and yellow. The four-color printing is also called CMYK printing method.

How to distinguish four-color printing and spot color printing?

There are two types of spot colors and four colors. How should we distinguish them?

Four-color printing:

The four-color printing is printed with four basic inks, blue, red, yellow, and black, using offset printing (like paper printing). Many different patterns can be printed. Careful observation with a magnifying glass can be seen on the printing. There are halftone dots (like the TV display, there are pixels, and the effect is enlarged by N times), so the four-color printing is actually a combination of halftone dots.

Spot color printing:

Spot color printing is compared with the color on the color card, and the ink is adjusted first, and then printed, so that only one color is printed. Of course, according to the customer's product design, there can be different shapes and different patterns. Spot colors are superimposed to form different colors and patterns. Because spot colors are not hit colors, there are no dots on the surface, and they look smooth.

Some differences between four-color and spot color printing:

Cost: The tinplate printing machine is a two-color machine (only two colors can be printed at a time, unlike four or six colors at a time like paper printing), so a four-color printing requires two passes.

For spot color printing, one spot color needs to be printed twice. Two spot colors can be printed at one time. Therefore, to print two spot colors, two passes must be printed. Therefore, the printing cost of two spot colors is the same as that of a four-color printing. The cost is the same. When you print four spot colors, the cost is the cost of two four-color printing, so the printing cost will increase.

Color: The four-color printing is the hit color, so each time the printing ink is slightly different, the hit color will have a certain deviation (because the printing is completed by the joint operation of the machine and the human, so it is batched During the second printing, it is impossible to adjust the ink mixing ratio to be absolutely correct. Therefore, there will be some deviations between each batch of printing in the four-color printing. The printing factory promises to keep the color consistency of the sample at 90%. about.

Spot color printing is done after adjusting the ink. The ink is adjusted according to the Pantone color card, so the color difference is a little less than the four-color printing.

The surface is beautiful: Because the four-color printing is a hit color, the dots on the printing are clear when viewed with a magnifying glass. Therefore, the surface of the four-color printing is relatively rough when you look closely.

The spot color printing has no dots, and the surface is relatively smooth, which is relatively good-looking. Of course, four-color printing can print colorful patterns, while spot colors can only print a single color. So the interior products are not the same, and the choice of tin box packaging printing is also different.

How to choose four colors or spot colors:

In general, if you need to produce tin box packaging with more complicated patterns, we recommend that customers choose four-color printing. If the pattern is relatively single and the color is only one or two, the choice of spot color printing will bring more highlights. Especially for a large area of a single color, it is better to choose a spot color, so a four-color pattern design, if there is a large area of a single color, you can also choose a four-color printing plus a spot color printing, of course, In this way, the production cost of the final tin box packaging is a bit higher.

Production capability:

1). Our company have two factories:one is tinplate coating and printing, and the other is tin can making , can supply one-stop service from plain tinplate, coated tinplate ,printed tinplate ,lacquered tinplate till the final tin cans.

2). Smooth production ability 4,000tons each month .

3). OEM/ODM , Free of charges of Logo design and printing on your goods .

Main markets:

Our products are mainly exported to USA, Egypt, UK, Russia, Germany, Myanmar, Canada, Malaysia, Argentina, Peru, Colombia, Saudi Arabia, UAE, and so on

Our service:

1. Pre-sale Service

1). Sample can be offered .

2). We have 20 years experience of design, manufacture and sell printed tinplate , we cherish every order from our honored customers.

3). We have full stock,and can deliver within short time.Many styles for your choices.

4). OEM and ODM order are accepted, Any kind of logo printing or design are available.

5). Good Quality + Factory Price + Quick Response + Reliable Service

6). All of our products are produced by our professional technician and skillful workers.we have our high-working-efficient export sales team, you can totally trust our service.

2. After you choose us

1. Deposit: We will inform you the deposit arrive at our account at the first time . And arrange to produce at once.

2. Favorable Sea Freight: Ourselves International Logistics will supply for you the favorable sea freight and the best transport plan .

3. Transportation safety guarantee: Our logistics having good-tracked system. Will inform you the goods transport status message at any time , until you pick up the goods.

3. After sale service

1. We are glad to supply the better suggestion of the price and products . Including the goods` stockpile and application .

2. Will supply the latest market price information for you at any time.

3. Welcome to visit our company . Insure you will have a good time in China.