Specification of Fashion Tin Steel Beverage Cans Beer:

Product name | Fashion Tin Steel Beverage Cans Beer |

Description | A good packaging is the best and most cost-effective advertisement for your products such as candy, nut, cookie,chocolate and more. The metal container we produced is your best choice for its high quality and competitive price . |

Specifications | Product size: large,mini,any size is accepted Material: 0.18~0.23mm thickness tinplate for your choice design:Welcome your own design , we will protect your copyright if you have the legal copyright. Features : Recycle and durable ,eco-friendly, offset printing with good safety ink Three-piece structure ( lid, body and base) Hinged lid Vivid picture embossing on tin body Height is adjustable |

Printing | CMYK printing on outside of whole tin cans transparent varnish for inside tin it can be different according to your request |

Features | Recycle and durable eco-friendly offset printing with good safety ink |

Surface | Varnish / matt, Embossing and debossing is acceptable |

Competitive price : | we are insist on competitive price for our customers to keep a long good relationships with each others |

Certificate | ISO 9001 |

Leadtime | 7-10 days for pre-production samples 25-30 days for mass production after sample approval |

Payment | 30% in advance,70% upon shipment |

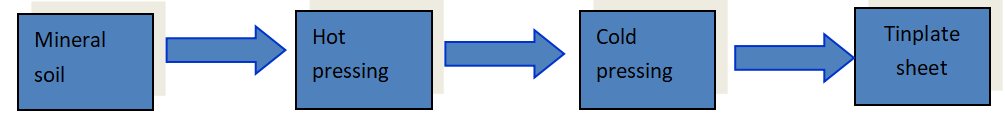

Tin Steel Beverage Cans raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of tinpate sheet can be extracted from 1.8 ton of iron ore

Quality assurance:

1) The Right Material, First Time: Quality is the hallmark of our reputation.

2) Strict quality control,ensure any product satisfied with yours application .

3) Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department

Classification of tin steel cans (cool drink tin):

Due to the various characteristics and advantages of tin steel materials, the application of tinplate is becoming more and more widespread. Tinplate packaging has gradually entered the food and beverage packaging materials, including food cans, beverange cans,grease cans, chemical cans, and other miscellaneous cans.

1. Food cans

Tinplate can ensure the hygiene of food, minimize the possibility of corruption, effectively prevent health risks, and also meet the canned food packaged by modern people in tinplate.

The need for fast and convenient diet is the first choice for food packaging containers such as tea packaging, coffee packaging, health product packaging, candy packaging, cigarette packaging, gift packaging, etc.

2. Beverage cans (soft can drinks)

Tinplate cans can be used to fill juice, coffee, tea and sports drinks, and can also be filled with cola, soft drinks, beer and other beverages. And the high workability of tinplate cans makes the can shape change a lot, no matter whether it is tall, short, large, small, or square, or round, it can meet the diversified needs of today's beverage packaging and consumer preferences.

3. Grease cans

Light can trigger and accelerate the oxidation reaction of oils and fats, reduce nutritional value, and may produce harmful substances. More serious is the destruction of oily vitamins, especially vitamin D and vitamin A. The oxygen in the air promotes the oxidation of food fats, reduces the biomass of proteins, and destroys vitamins. The tint opacity and the effect of sealing the air are the best choices for packaging fat foods.

4. Chemical cans

Tinplate is sturdy, has good protection, does not deform, is shock-resistant, and fire-resistant. It is the best packaging material for chemicals.

5. spray cans

Tinplate cans that can withstand high temperatures and pressures, especially suitable for high-pressure filling spray cans.

6. Dry miscellaneous cans

Varying cans and beautifully printed biscuit barrels, stationery boxes, and milk powder cans are all tinplate products.

FAQ:

Q: Are your tinplate products food safe?

A: Yes, all of our tinplate products come with food grade materials and FDA certification. Please call us or email us to get latest test report.

Q: What is your MOQ?

A: In general, 1000 to 10000 pcs for normal size.

Q: Do you send me a price list?

A: Our price is based on box size, shape, printing, packing, accessories, quantity, and etc. It is meaningless to make a standard price list. Please let us know your product specification and we will offer you our best price asap.

Q: Can I get samples before placing order and how long for a sample?

A: Yes, stock sample are always free. Delivery time: 1-3 days. If customized samples, cost will be depending on your artwork. 7-15 days for sample lead time.

Q: What is the sampling time?

A: In general 7-10 days.

Q: What is the mass production time?

A: In general 30-35 days.

Q: What is the leadtime for developing new mold?

A: In general, it takes 20-25 days to complete new mold with sampling.

Q: Do you provide accessories?

A: Yes, we can provide customer kinds of accessories to match our tinplate products. Such as foam, sponge, EVA, flocking blister tray; card box, white box; PVC/ PET sheet; paper label and beaded, lock, handle, etc.