Specification of Golden Oval Tuna Can Tin Container:

Item name | Golden Oval Tuna Can Tin Container |

MOQ | 20000pcs |

Size | large,mini,any size is accepted |

Material | First Grade Tinplate, 0.18~23mm thickness tin for your choice |

Features | Recycle and durable |

Certificate | SGS test report and ISO 9001/14001:2004, to assure our good quality. |

Leadtime | 7-10 days for pre-production tins samples |

Payment Method | TT: 30% in advance,70% upon shipment |

Features of Golden Oval Tuna Can Tin Container:

Food grade material for coating and printing

Multiple printing processes

3000 sets of moulds are available

Various styles are available

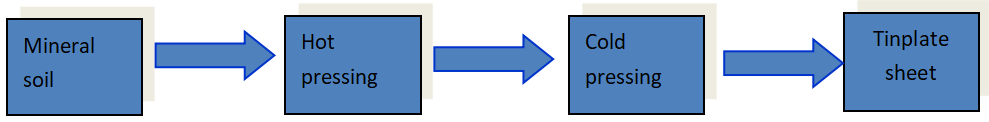

Tuna tin can tin container tinplate raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of tinpate sheet can be extracted from 1.8 ton of iron ore

Quality assurance of tuna fish can:

1) The Right Material, First Time: Quality is the hallmark of our reputation.

2) Strict quality control,ensure any product satisfied with yours application .

3) Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department

What is tuna can?

Tuna fish can is one kind of tinplate cans,Tinplate cans are commonly called tin cans, tin boxes, which are tins made of tinplate. Tinplate is made of tin on the surface. For protection. Generally speaking, in order to exquisite packaging, printing is used, commonly known as printed tin cans.

Basic requirements for Tuna Can Tin Container tin box packaging:

Nowadays, tin box packaging is more and more widely used in people's lives, and people's requirements for tin box packaging are becoming more and more strict, especially food tin boxes Tuna Can Tin Container and pharmaceutical tin boxes.

1. Security. As a food tin container, because it is in direct contact with food, the most important and most basic thing is that it is harmless to the human body and ensures that the food meets the health regulations of various countries. Tuna Can Tin Container for export must generally comply with relevant sanitary standards of the FDA and the importing country.

2. Sealability, because tuna is usually spoiled due to microorganisms, the Tuna Can Tin Containe must have reliable sealability, so that after food is sterilized by heating, it can no longer be contaminated by external microorganisms.

3. Corrosion resistance. A large part of the food in the tin box has certain nutrients, organic acids and certain compounds, which will decompose during the high-temperature and high-pressure sterilization process. To ensure the long-term storage of food, the iron box selected must have good corrosion resistance.

4. Convenience. As a container for storing food, it must be convenient for consumers to carry and take food, and it must have the conditions for long-distance transportation.

5. It is suitable for industrial production. During the production process, the iron box must withstand various mechanical stamping, crimping, welding and other processes, and the demand is large and mass production is required. Therefore, it must have factory mechanized and automated production requirements. It must have high efficiency, stable quality, low cost, and meet the requirements of modern production management.