Specification of Tin Plate Coil Printing For drinking Cans:

Product name | Tin Plate Coil Printing For drinking Cans |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.18~0.23mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

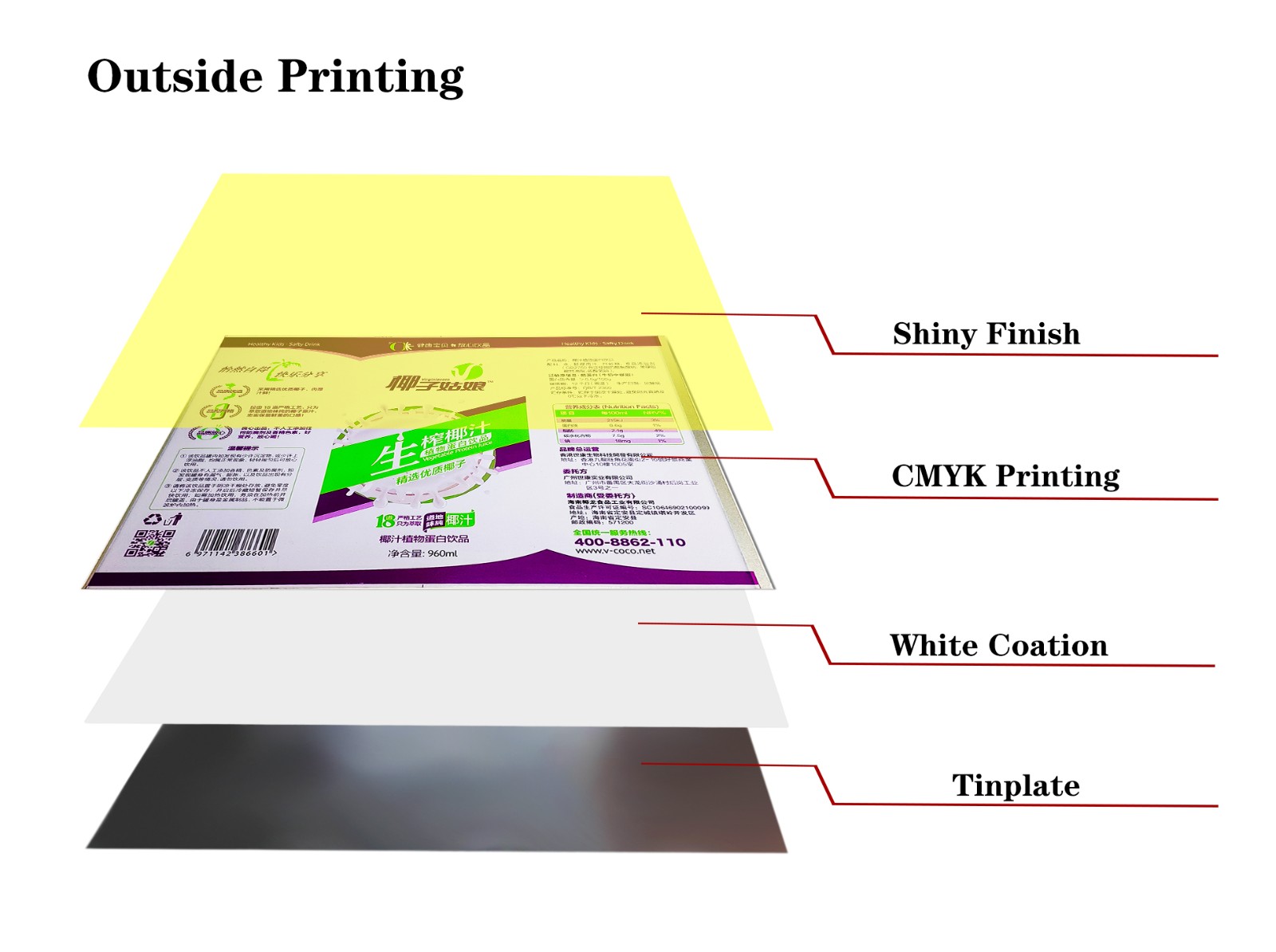

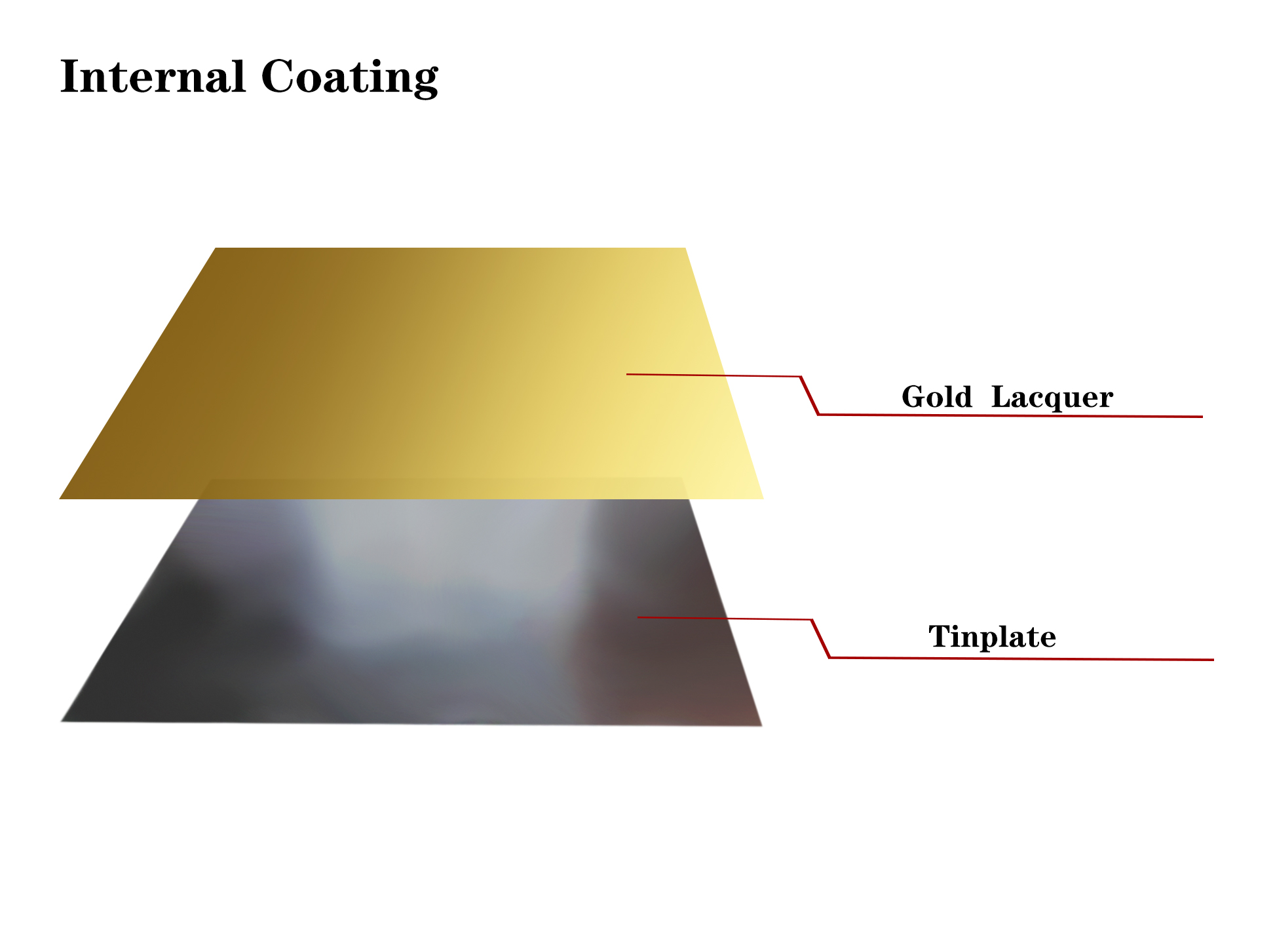

Internal coating | White coation or Gold lacquer |

Outside printing | White coation+CMYK Printing+transparency lacquer |

Application | For any drinking cans packing Box, Can, Bucket and custom beer cans etc(Food, oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

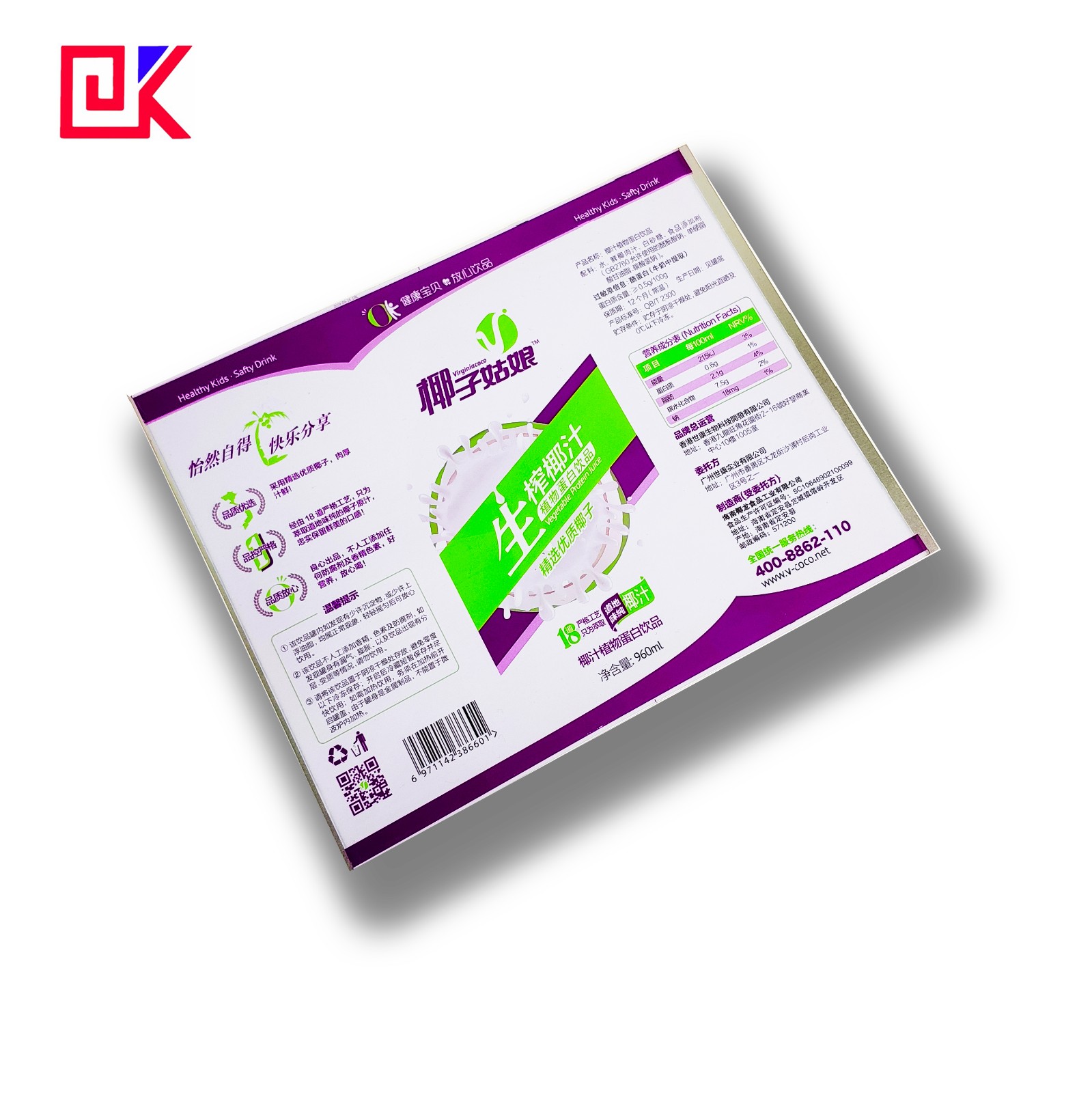

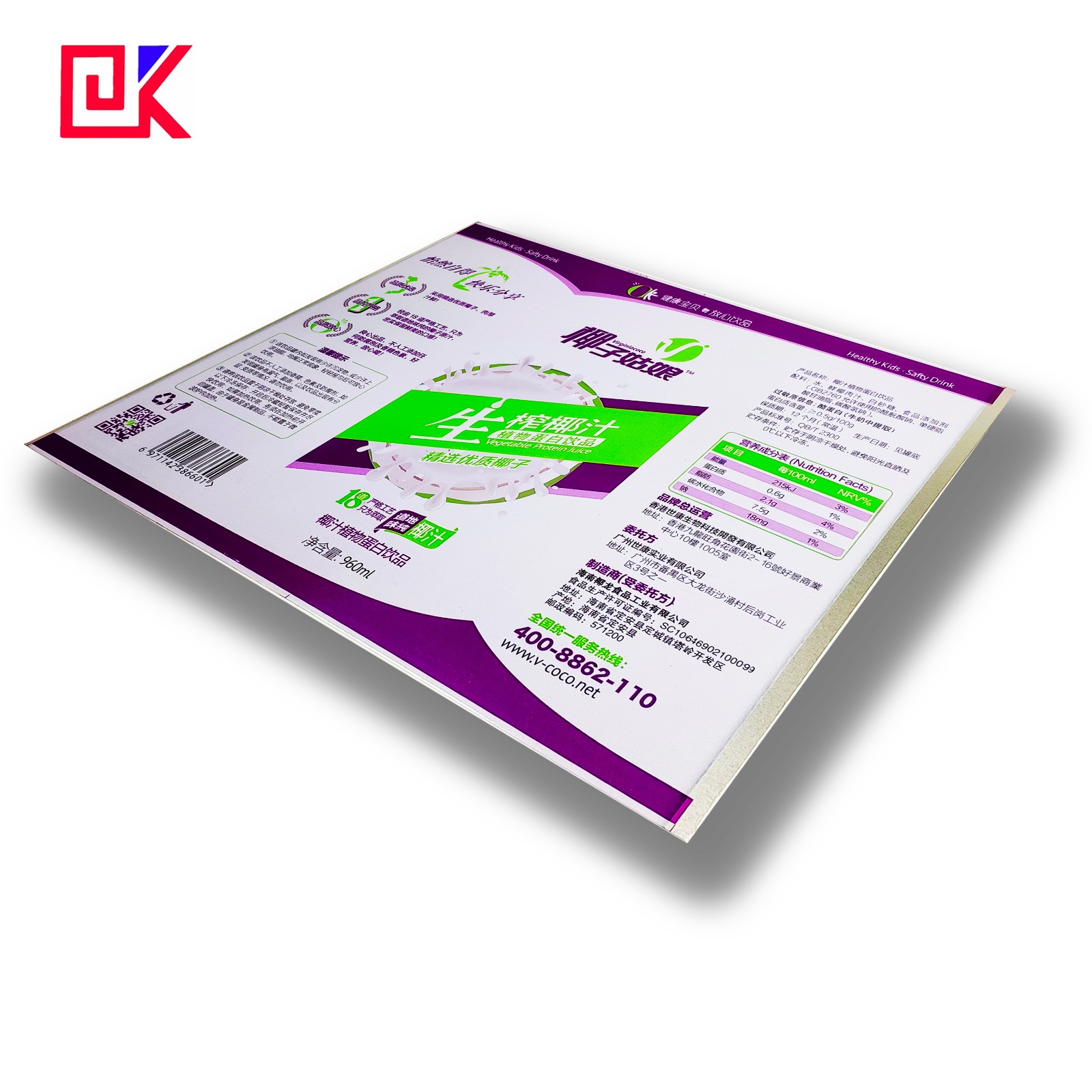

Product Show

Product design

Product Detail

Outside Printing

Internal Coating

All of our products support customization, if you need please feel free to contact us.

Standard of tin plate coil temper:

Standard Material | Q/BQB 455-2009 | JIS G3315-2008 | ASTM A623M-08 | EM 10202:1989 | EN 1020:2001 | ISO 11950:1995 |

Single Reduce | - | T-1 | T-1(49) | T50 | TS230 | TH50+CE |

T-1.5 | - | - | - | - | - | |

T-2 | T-2 | T-2(T53) | T52 | TS245 | TH52+CE | |

T-2.5 | T-2.5 | - | - | TS260 | TH55+CE | |

T-3 | T-3 | T-3(T57) | T57 | TS275 | TH57+CE | |

T-3.5 | - | - | - | TS290 | - | |

T-4 | T-4 | T-4(T61) | T61 | TH415 | TH61+CE | |

T-5 | T-5 | T-5(T65) | T65 | TH435 | TH65+CE | |

Double Reduce | DR-7M | - | DR-7.5 | - | TH520 | - |

DR-8 | LR-8 | DR-8 | DR550 | TH550 | TH550+CE | |

DR-8M | - | DR-8.5 | - | TH580 | TH580+CE | |

DR-9 | DR-9 | DR-9 | DR620 | TH620 | TH620+CE | |

DR-9M | DR-9M | DR-9.5 | DR-660 | - | TH660+CE | |

DR-10 | DR-10 | - | - | - | TH690+CE |

Tin coating weight on tin plate coil:

Classification | Designation of | Nominal tin (g/m2) | Min average (g/m2) | Remark |

Equai tin coating(E) | 1.1/1.1 | 1.1/1.1 | 1.8 | All specification |

2.2/2.2 | 2.2/2.2 | 4.0 | All specification | |

2.8/2.8 | 2.8/2.8 | 5.0 | All specification | |

5.6/5.6 | 5.6/5.6 | 10.5 | All specification | |

classification | 2.2/1.1 | 2.2/1.1 | 2.0/0.9 | All specification |

2.8/1.1 | 2.8/1.1 | 2.25/0.9 | All specification | |

5.6/1.1 | 5.6/1.1 | 5.05/0.9 | All specification | |

2.8/2.2 | 2.8/2.2 | 2.25/2.0 | All specification | |

5.6/2.2 | 5.6/2.2 | 5.05/2.0 | All specification | |

5.6/2.8 | 5.6/2.8 | 5.05/2.25 | All specification |

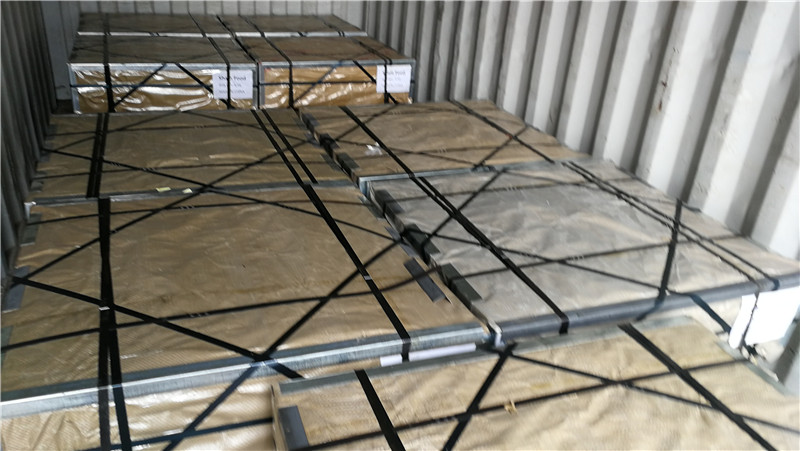

Packaging & Loading:

Packaging for tinplate coil:Anti-rust paper+Metal cover+Corner cap protected+Wood skids.

Packaging for tinplate sheet: Thin plastic film+Anti-rust paper+Metal cover+Metal corner cap protected+Binding strap+Pallet.

Loading by 20 feet container: about 20~25 tons

Packaging

Loading

Packaging

Packaging

Main markets:

Our products are mainly exported to USA, Egypt, UK, Russia, Germany, Myanmar, Canada, Malaysia, Argentina, Peru, Colombia, Saudi Arabia, UAE, and so on

Our advantage:

Whether you need structural steel, complex miscellaneous metals, or stock steel material you will get:

1. The Right Material, First Time: Quality is the hallmark of our reputation.

2. On Time Delivery: Your projects stay on schedule.

3. Ongoing Communication: Everyone is fanatically responsive to your needs. We handle the project so there are no surprises for you.

4. ISO Certification: We help you meet your goals plus the goals of your owners/customers.