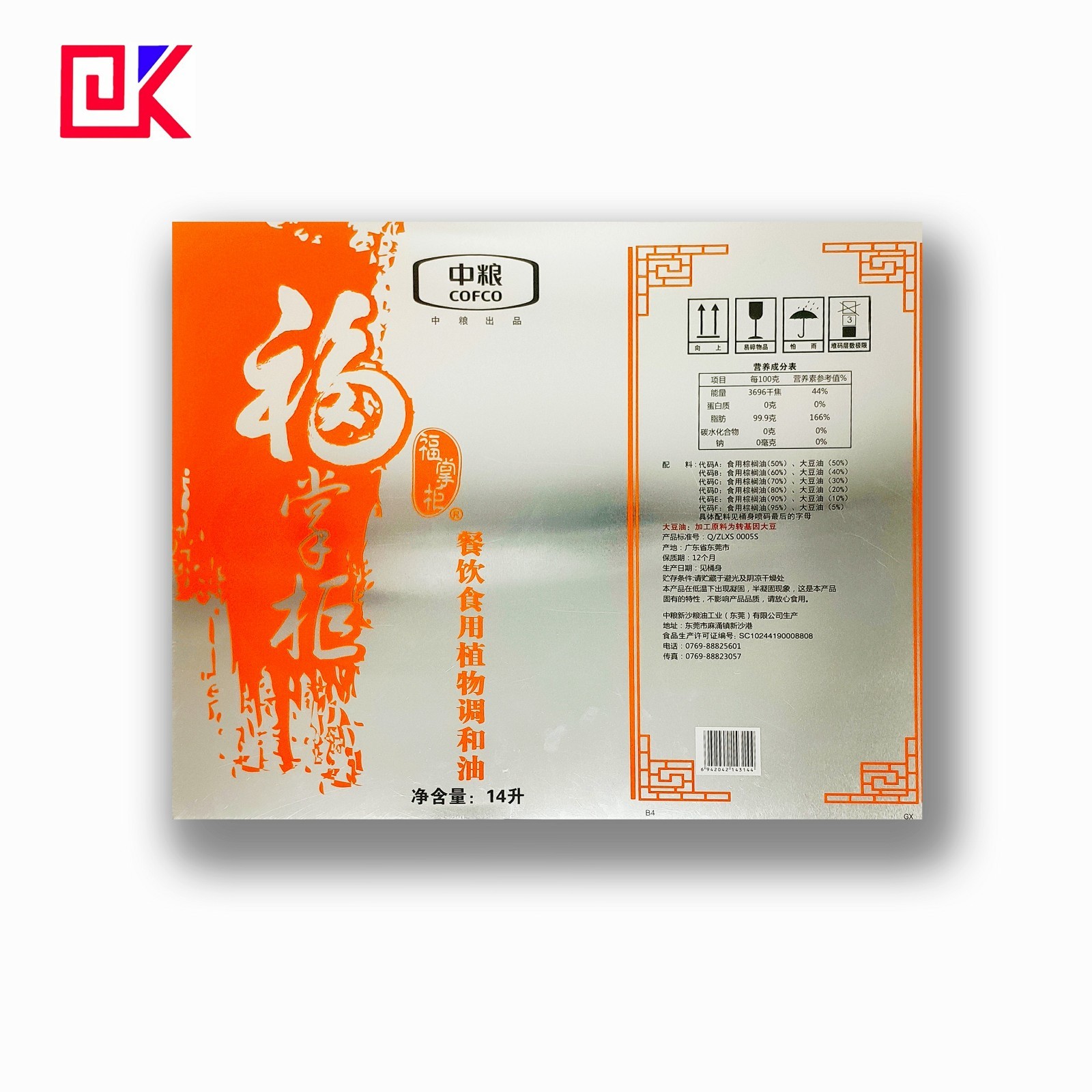

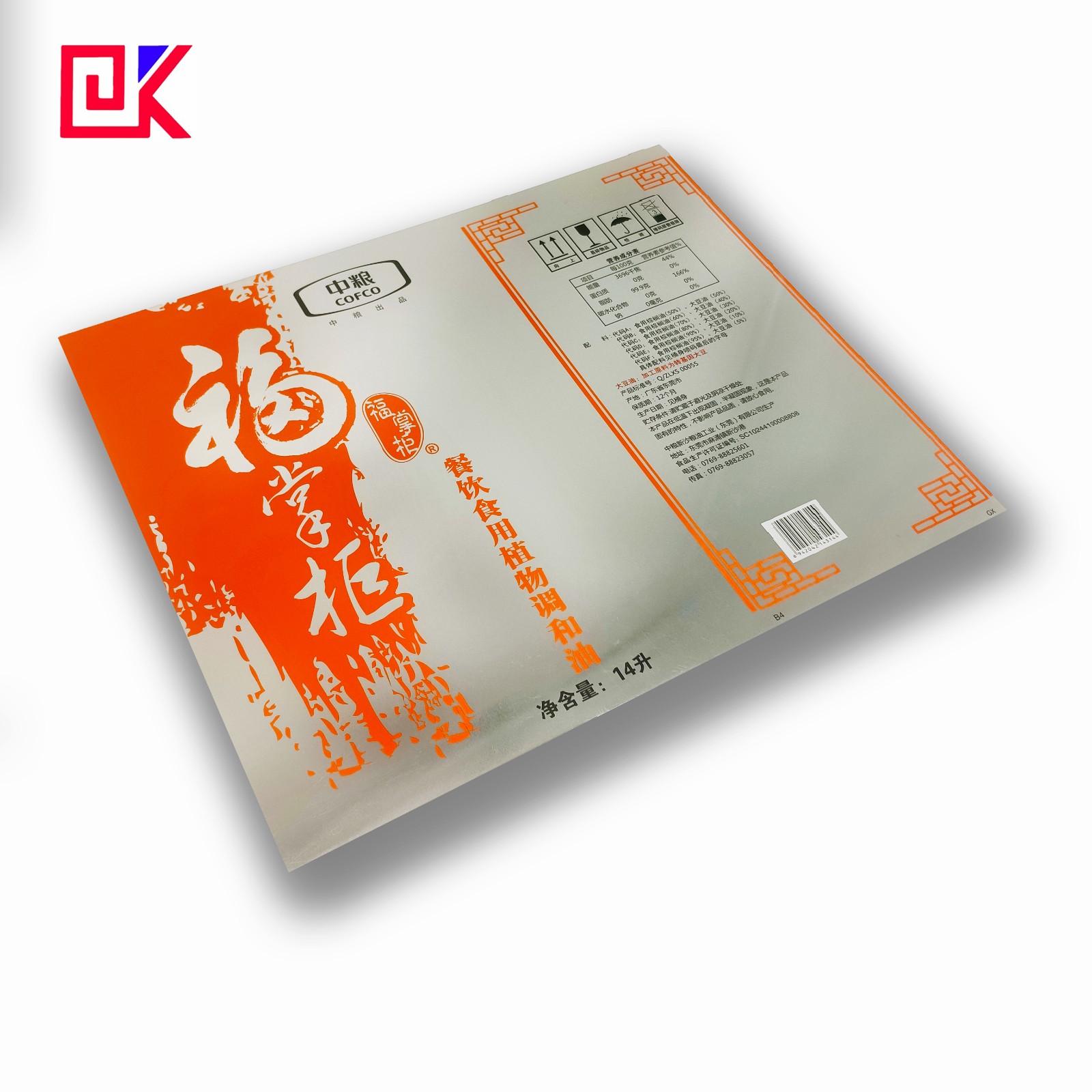

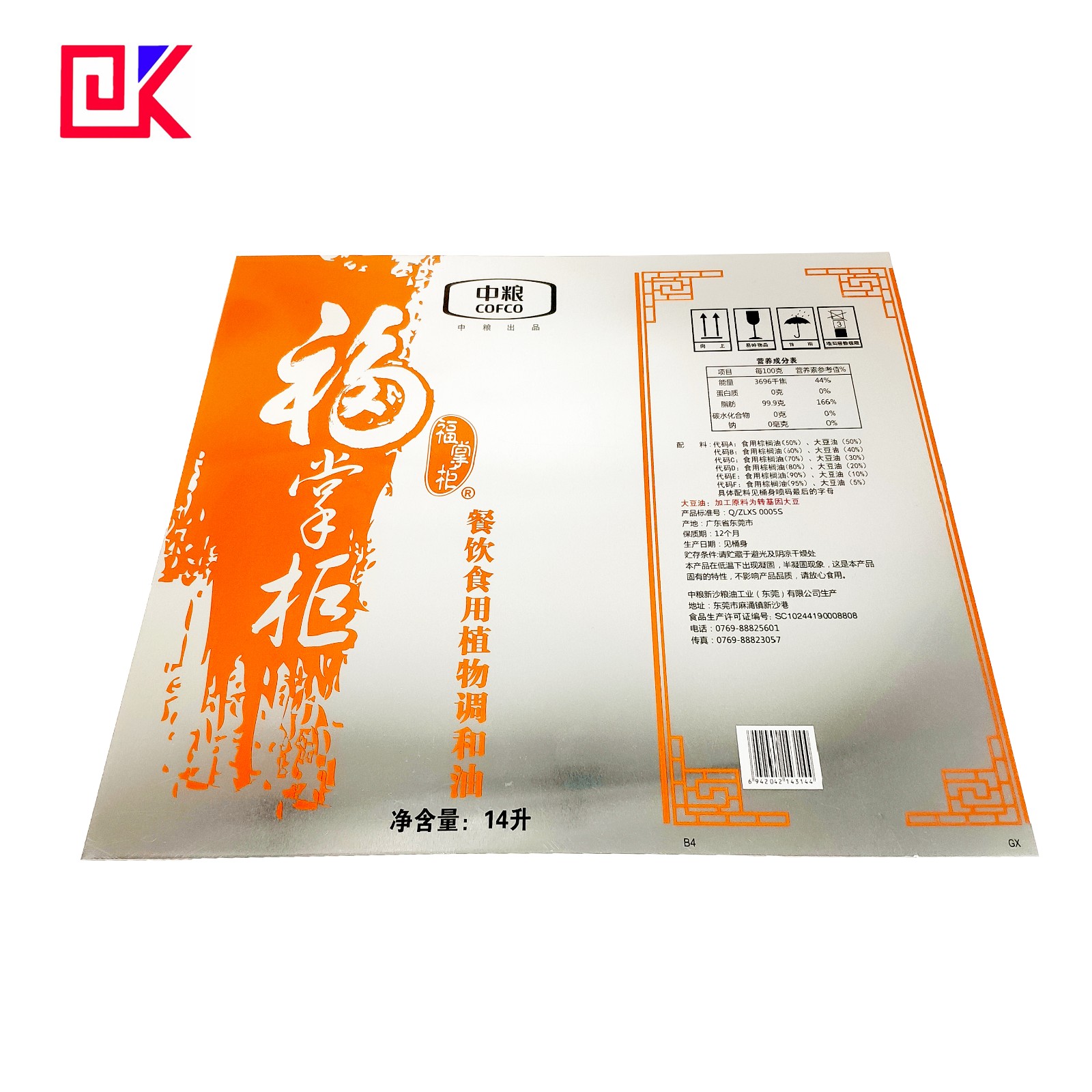

Specification of Tin Plate Sheet Printed For oil Tin:

Product name | Tin Plate Sheet Printed For oil Tins |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.21~0.28mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

Internal coating | White coation or Gold lacquer |

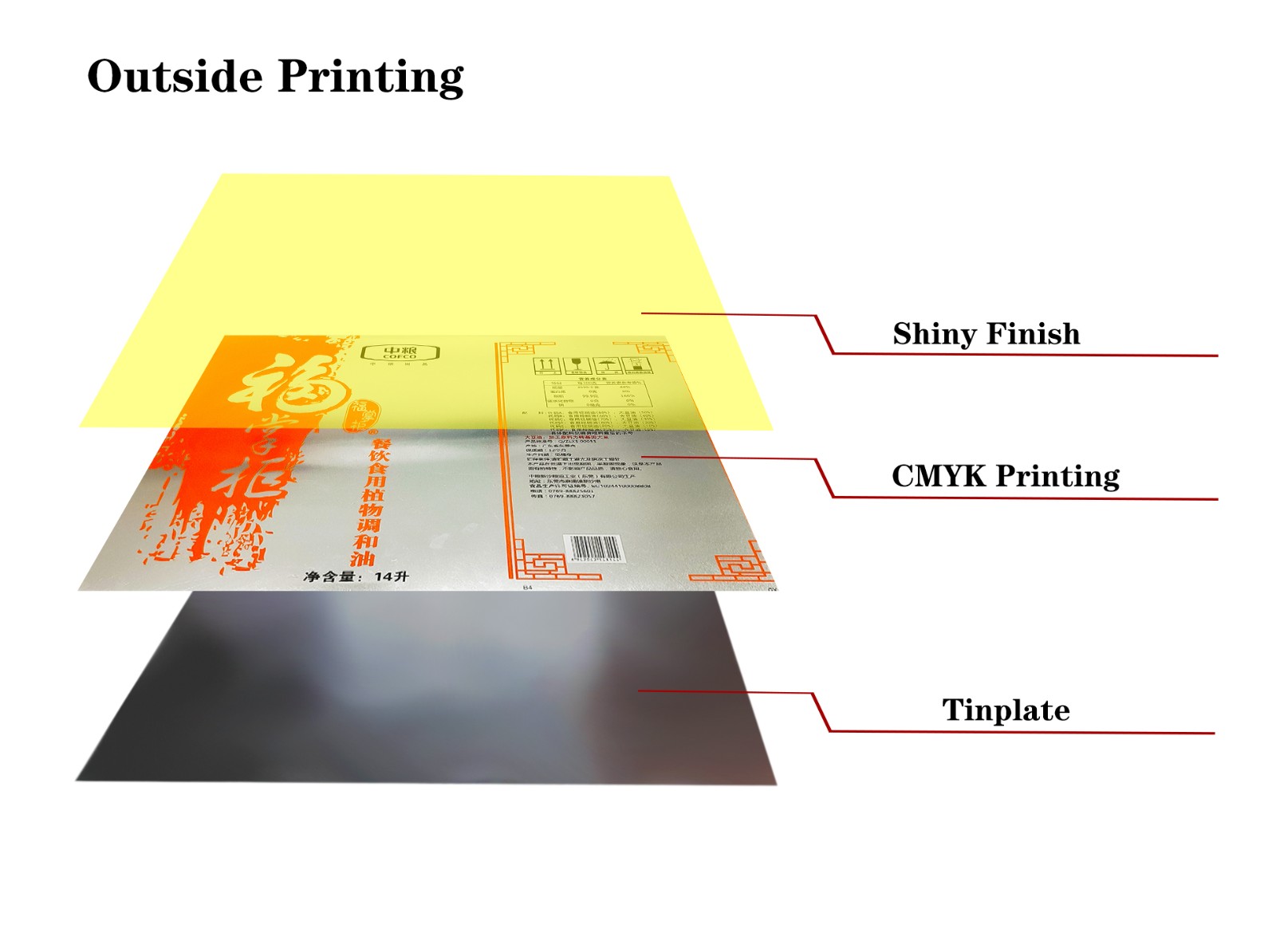

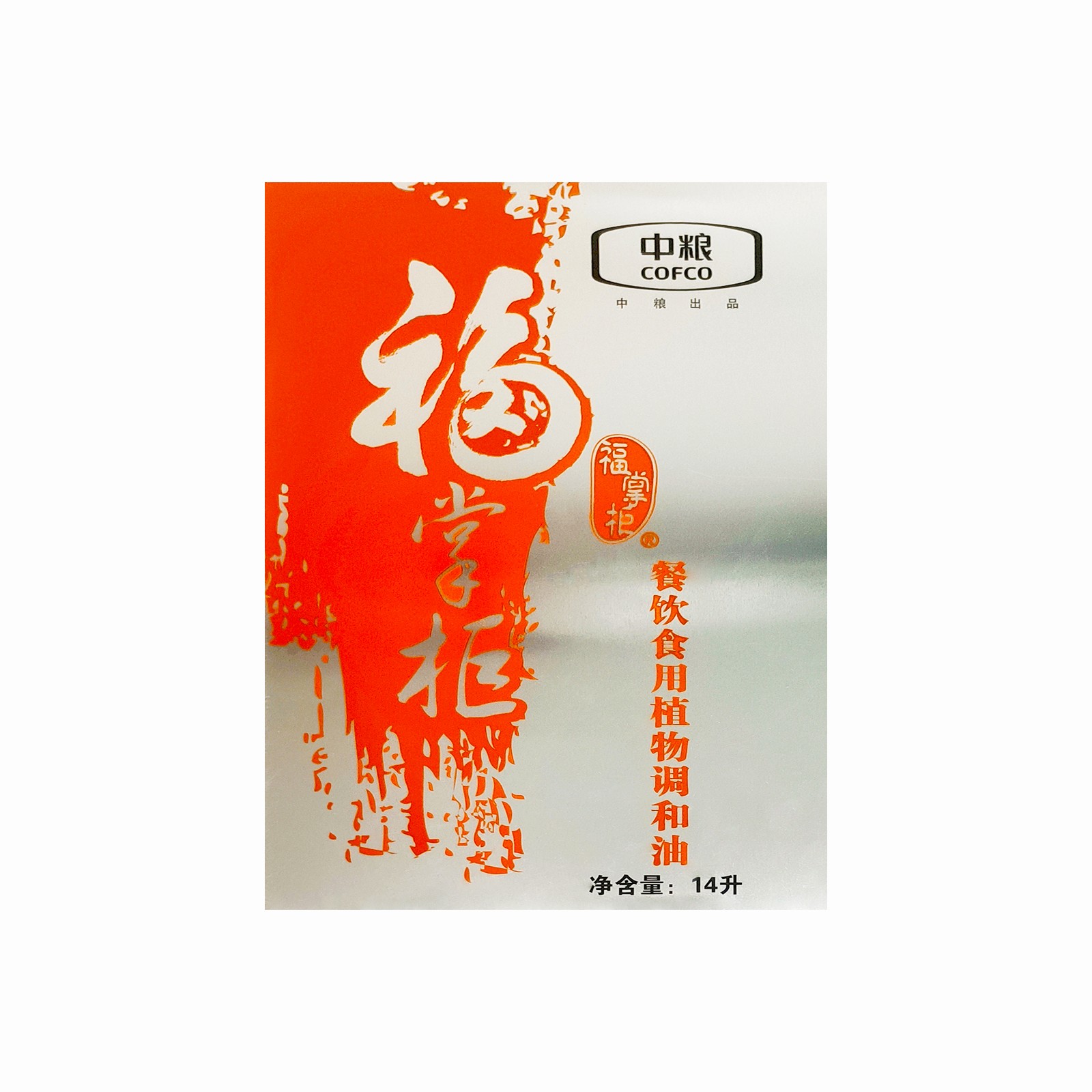

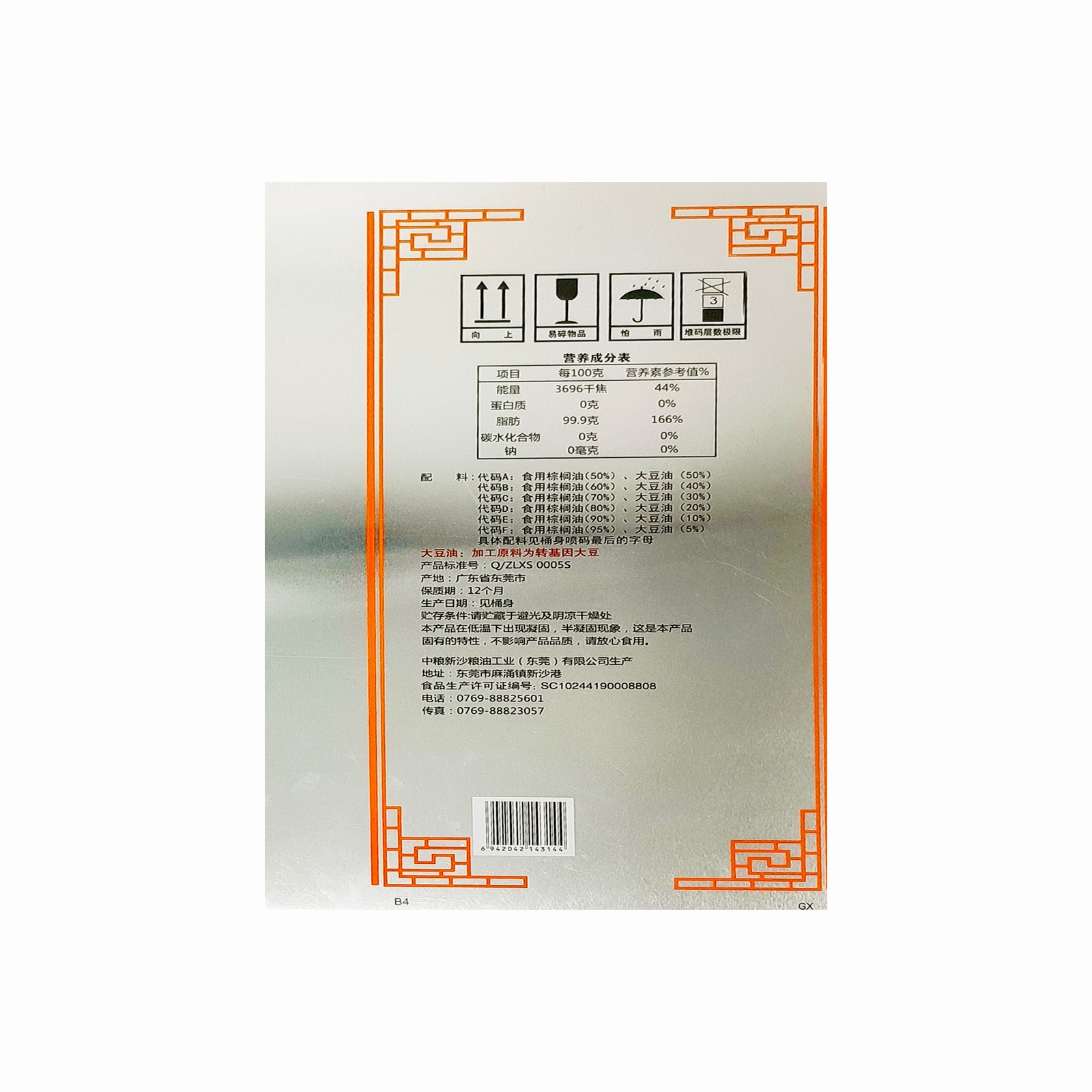

Outside printin | CMYK Printing+transparency lacquer |

Application | For any packing Tin, Box, Can, Bucket, etc(Food, oil, medicines, cosmetics, perfume,toys, metal oil can, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

Product Title

Product Title

Product Title

Product Title

Product Title

Tin coating weight on tin plate sheet:

Tinplate Status | Coating Status | Former Coat | Coating W. Code | Normal C-W | Min. Ave. C-W | Remarks |

EPT | Equally Coating (E) | 10# | 1.1/1.1 | 1.1/1.1 | 0.9/0.9 | All specifications |

20# | 2.2/2.2 | 2.2/2.2 | 1.8/1.8 | |||

25# | 2.8/2.8 | 2.8/2.8 | 2.5/2.5 | |||

50# | 5.6/5.6 | 5.6/5.6 | 5.2/5.2 | |||

75# | 8.4/8.4 | 8.4/8.4 | 7.8/7.8 | |||

100# | 11.2/11.2 | 11.2/11.2 | 10.1/10.1 | |||

Classified Coat (D/A) | 25#/10# | 2.8/1.1 | 2.8/1.1 | 2.5/0.9 | ||

50#/10# | 5.6/1.1 | 5.6/1.1 | 5.2/0.9 | |||

50#/25# | 5.6/2.8 | 5.6/2.8 | 5.2/2.5 | |||

75#/25# | 8.4/2.8 | 8.4/2.8 | 7.8/2.5 | |||

75#/50# | 8.4/5.6 | 8.4/5.6 | 7.8/5.2 | |||

100#/25# | 11.2/2.8 | 11.2/2.8 | 10.1/2.5 | |||

100#/50# | 11.2/5.6 | 11.2/5.6 | 10.1/5.2 | |||

100#/75# | 11.2/8.4 | 11.2/8.4 | 10.1/7.8 |

Tin plate sheet surface state:

Marks | Suface state | Characteristics |

B | Bright rough | Glazed surface obtained after melting treatment of electroninned smooth raw material strip featuring certain oriented rubstone figure. |

R | Stone rough | Glazed surface obtained after melting treatment of electroninned raw material strip featuring certain oriented rubstone figure. |

S | Silver rough | Glazed surface obtained after melting treatment of electroninned raw material strip with rough matt surface. |

Production capability:

1). Our company have two factories:one is tinplate coating and printing, and the other is tin can making ,

can supply one-stop service from plain tinplate, coated tinplate ,printed tinplate ,lacquered tinplate till the final tin cans.

2). Smooth production ability 4,000tons each month .

3). OEM/ODM , Free of charges of Logo design and printing on your goods .

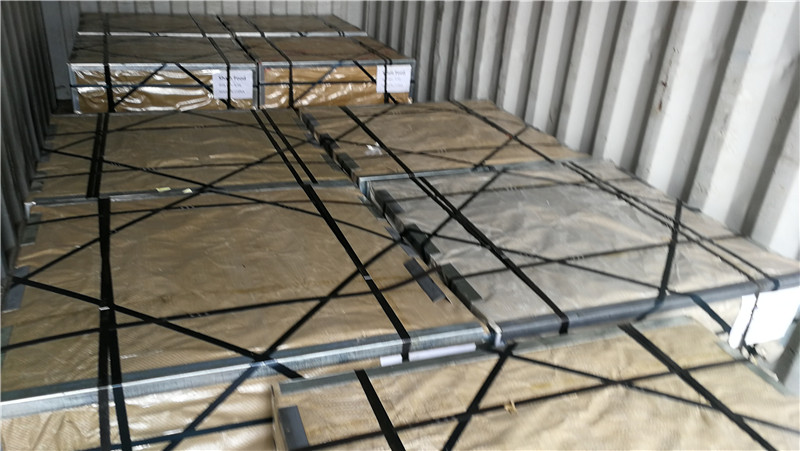

Packaging & Loading:

Packaging for tinplate coil:Anti-rust paper+Metal cover+Corner cap protected+Wood skids.

Packaging for tinplate sheet: Thin plastic film+Anti-rust paper+Metal cover+Metal corner cap protected+Binding strap+Pallet.

Loading by 20 feet container: about 20~25 tons

Packaging

Packaging

Loading

Loading

Surface properties and printing fastness of tin plate sheet printed:

1. Tinplate surface properties

The surface properties of tinplate, that is, the surface condition and surface quality, are bad. There may be flaws, pits, wrinkles, dust, rust and other defects on the tinplate surface. From the perspective of the tinplate structure, the tinplate surface often has a very thin oil film. And generally it is electroplated, so the surface is relatively smooth. From the relationship between the specific surface area of the solid surface and the adsorption force, the adsorption force of tinplate is not very good.

2. Surface properties affect printing fastness

Tinplate printing is mainly offset lithography, and the process is as follows:

The surface roughness of tinplate is one of the important factors affecting the printing fastness. The surface of the tinplate substrate is generally smooth. Although some organic coatings also have strong adhesion on smooth surfaces, the overall absorption is poor and the adhesion is small, making the coating layer and ink layer adhere fast and dry. affected.

3. Influence of oil film layer

In the tinplate structure, there is an oil film on the surface. This oil film is to prevent tinplate from rusting during storage and rubbing against each other during transportation, which will greatly reduce the adhesion of the coating and ink. Therefore, the control of the amount of oil film is very important. At present, tinplate produced in various countries in the world does not have a certain standard for the thickness of the oil film. Generally, the amount of oil applied is controlled at 2 to 4 mg / m2, but some are above 6 mg / m2. If the amount of oil is too much, it will affect the printing quality of tinplate, so that the paint and ink layer cannot completely wet the tinplate surface, the adhesion performance is poor, and "pinholes" are easily generated in the ink layer after curing. The "pinhole" will cause the adhesion between the ink layer and the tinplate to decrease. Therefore, when the tinplate surface is coated with a high amount of oil, that is, above 6mg / m2, the tinplate should be pre-baked once before printing, so that too much oil film will evaporate.

In addition, the smooth tinplate surface will not only reduce the ink's adsorption force and make the printing fastness worse, but the poor adsorption performance will cause the ink to dry slowly and have poor conjunctivities, which will affect the adhesion fastness and abrasion resistance of the ink layer. As a metal material, when tinplate encounters high air humidity and a large temperature difference, it will form many small water drops on the tinplate surface, which will also reduce its adsorption and affect printing fastness.

4. Influence of oxide layer

In addition to the oil film on the tinplate surface, which will affect the adsorption force, the second oxide film in the tinplate structure will also affect the adhesion of the ink. There is a thin oxide film on the surface of the tin layer of tinplate. The structure of this oxide film is unstable and will continue to oxidize and thicken. It may even cause the ink layer on the oxide film to fall off, causing the ink adhesion performance to be lost. Therefore, tinplate should be passivated after tin plating to improve the stability of the oxide layer, hinder the growth of the oxide film, and maintain the stability of ink adsorption.