Specification of Tin Plate Sheets For Chemical Tins:

Thickness | 0.20~0.38mm |

Width | 700~1200mm |

Material | MR SPCC |

Tin Coating | 1.1/1.1, 2.8/2.8/,5.6/5.6 |

Temper | T1~T6/DR7~DR10 |

Coil Weight | 3~10 MT |

Oiling | DOS |

Surface Finish | Bright, Stone, Silver, Matt |

Annealing | CA, BA |

Packing | Wrapped completely with an inner cover of plastic or water proof papers with corners pertected |

Product Show

Product Detail

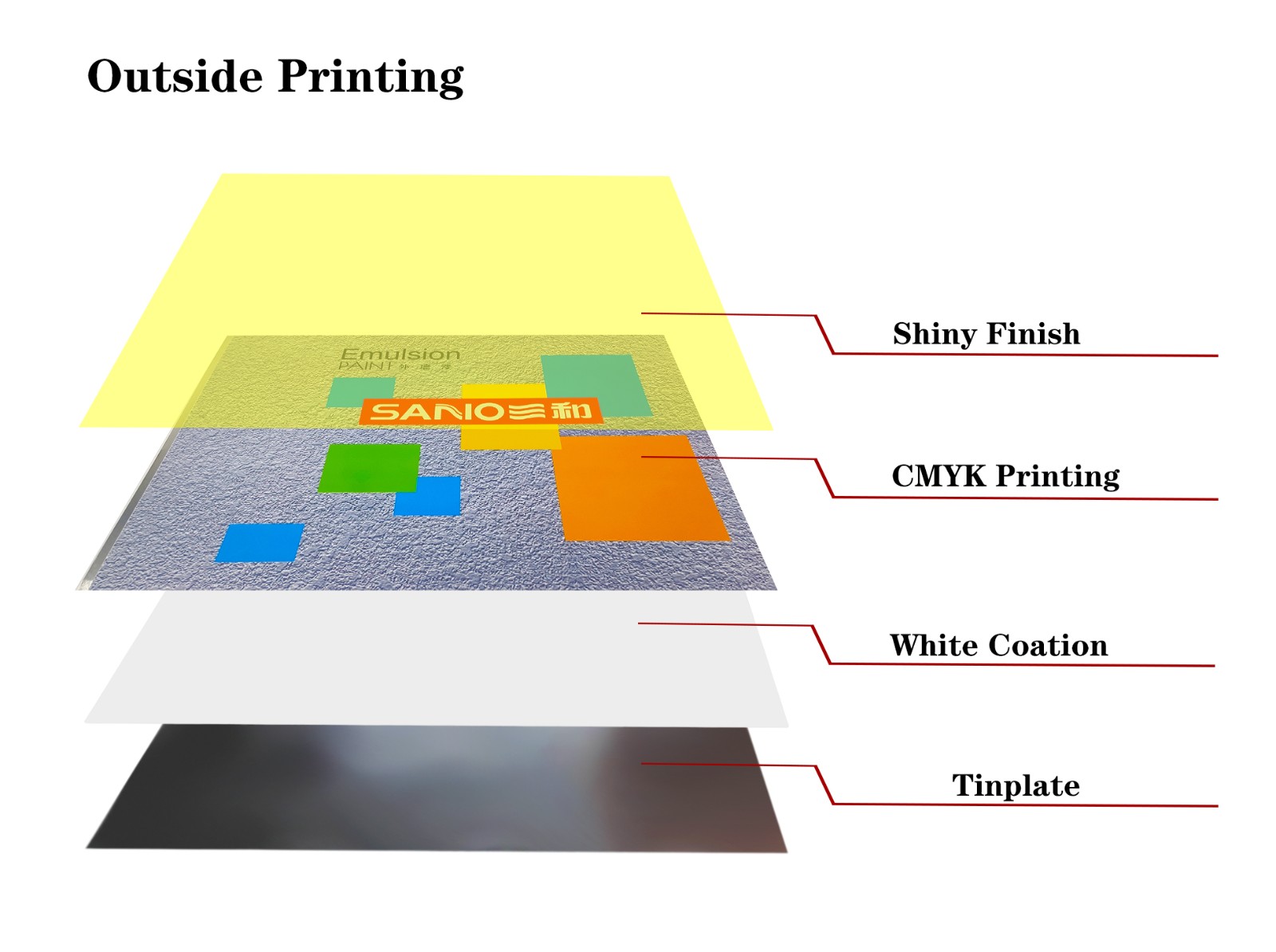

Printing Detail

Product Title

Product Title

All of our products support customization, if you need please feel free to contact us.

Composition of tin plate sheet:

tin plate sheet is mainly composed of five parts: steel substrate, tin-iron alloy layer, tin layer, oxide film and oil film. The thickness, composition and performance of each part are shown in Table 1.

Table 1: Thickness, composition and properties of each part oftin plate sheet:

Name | thickness | composition | properties |

oil film | 2~5mg/cm² | Cottonseed oil or malonic acid diester | Lubrication and rust prevention |

oxide film | 1~3mg/cm² (Single-side coating) | Ferrous oxide, tin oxide, chromium oxide, metallic chromium | After chemical treatment, it has the functions of anti-rust, discoloration and anti-sulfide |

tin layer | 5.6~22.4mg/cm² | Pure tin | Beautiful, easy to weld, corrosion-resistant and non-toxic |

tin-iron alloy layer | <1g/cm² | Tin-iron alloy crystals | Corrosion resistance, but too thick for poor processability and solderability |

steel substrate | 0.2~0.3mm | Low-carbon steel | Good processing performance, with certain strength after can making |

Introduction to tin plate sheet:

tin plate sheet is referred to as tin plate, commonly known as tinplate, which is a low-carbon thin steel plate with tin plating on both sides, with a thickness of about 0.15 to 0.45mm. Among them, metal tin is non-toxic, odorless, soft and so on. It adheres to the steel substrate, so that the steel substrate has good welding and processing performance.

Characteristics of tin plate sheet:

The opacity of tinplate, and the tin on the iron will interact with the oxygen remaining in the tin box during filling, which reduces the possibility of being oxidized for the packaging contents and is essential for its preservation; the metal of tinplate The ductility is good, so that more complex tank shapes can achieve high precision and high speed production. The good rigidity makes the produced tin boxes able to withstand collisions, vibrations and stacking, which is convenient for transportation and storage. It is easy to recycle, can be recycled, and the environmental protection of tinplate is better than plastic and paper packaging. The above characteristics make tinplate packaging the packaging material of many products for many companies. The most important thing is that its metal texture will reflect the preciousness that plastic packaging and paper packaging do not have.

Not only does tinplate have excellent properties suitable for packaging materials, but tinplate can be made into different shapes, which makes the packaging container more changeable and promotes the growth of product sales. It can be said that tinplate packaging is a creative labor product combining art and technology.

Tin Plate Sheets classification:

According to different tin plating processes, tinplate can be divided into two types: hot-dip tinplate and electroplated tin plate.

1. Hot-dip tin plate is made of tin coating with liquid coating process. Its coating is thick, and the thickness is difficult to control. The amount of tin consumed is large, so its application is limited.

2. Electroplated tin plate, also known as cold-rolled tinplate, is plated on steel substrate .The tin film is evenly plated on it, and the plating methods mainly include alkaline plating method, halogen plating method and boron fluoride plating method.

Tin Plate Sheets of application:

In the packaging industry. Because metal products have the characteristics of sturdiness and durability, especially the chemical tinplate and chemical cans have a long storage time and good freshness. If they are exquisitely shaped and designed with high-end color printing, they can not only increase the added value of the product, Improve economic efficiency, but also has valuable treasure value.

in children's toys. Because tin plate has excellent ductility, it can be made into a variety of toy products with a certain process design and printing, which increases the fun of children.