Specification of Offset Printing Metal Tin Sheet For Tea Cans:

Product name | Offset Printing Metal Tin Sheet For Tea Cans |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.20~0.28mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

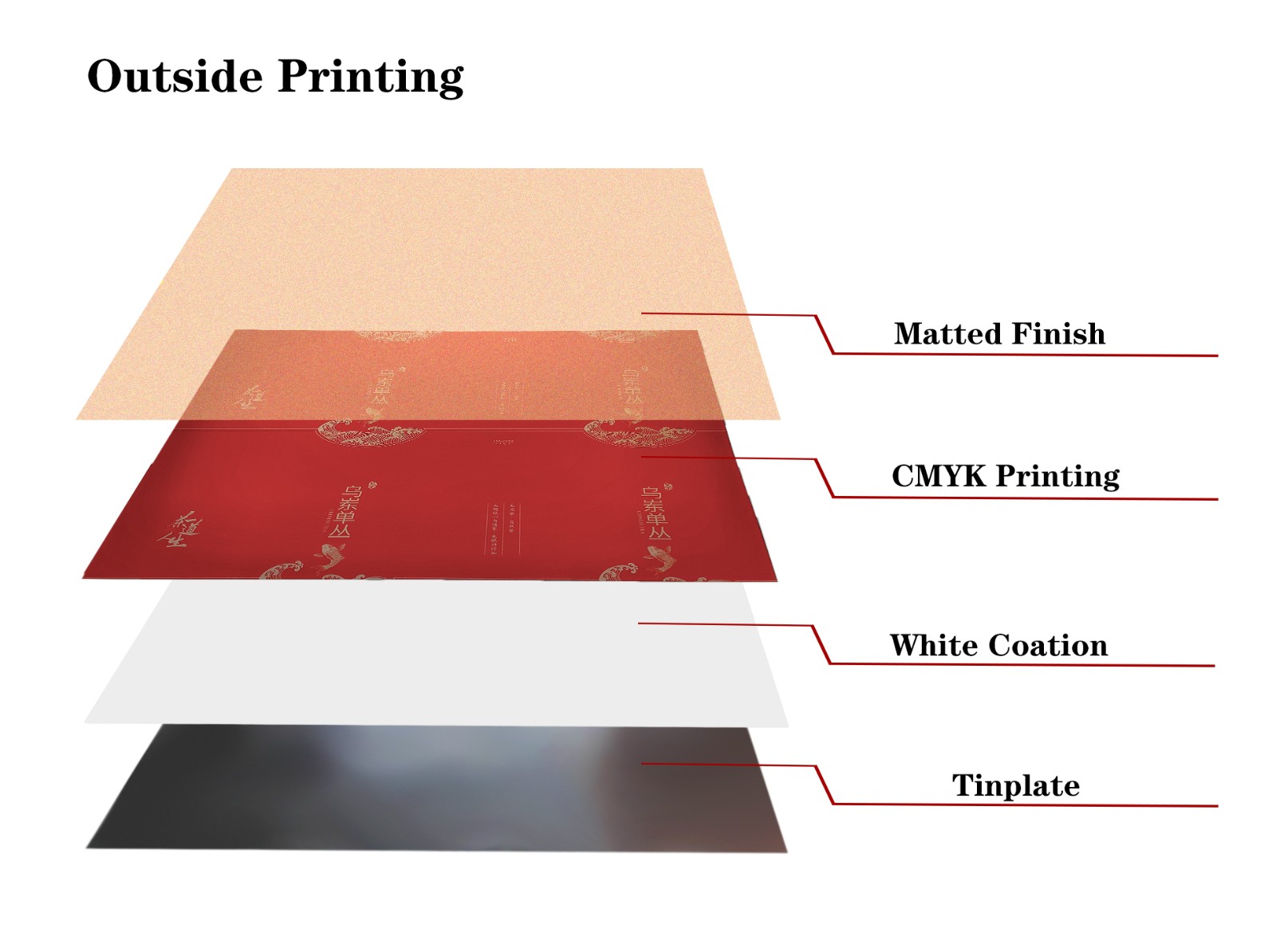

Internal coating | White coation or Gold lacquer |

Outside printing | White coation+CMYK Printing+transparency lacquer |

Application | For any packing Box, canned tea, Bucket, custom tea tins etc(Food, oil,tea, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

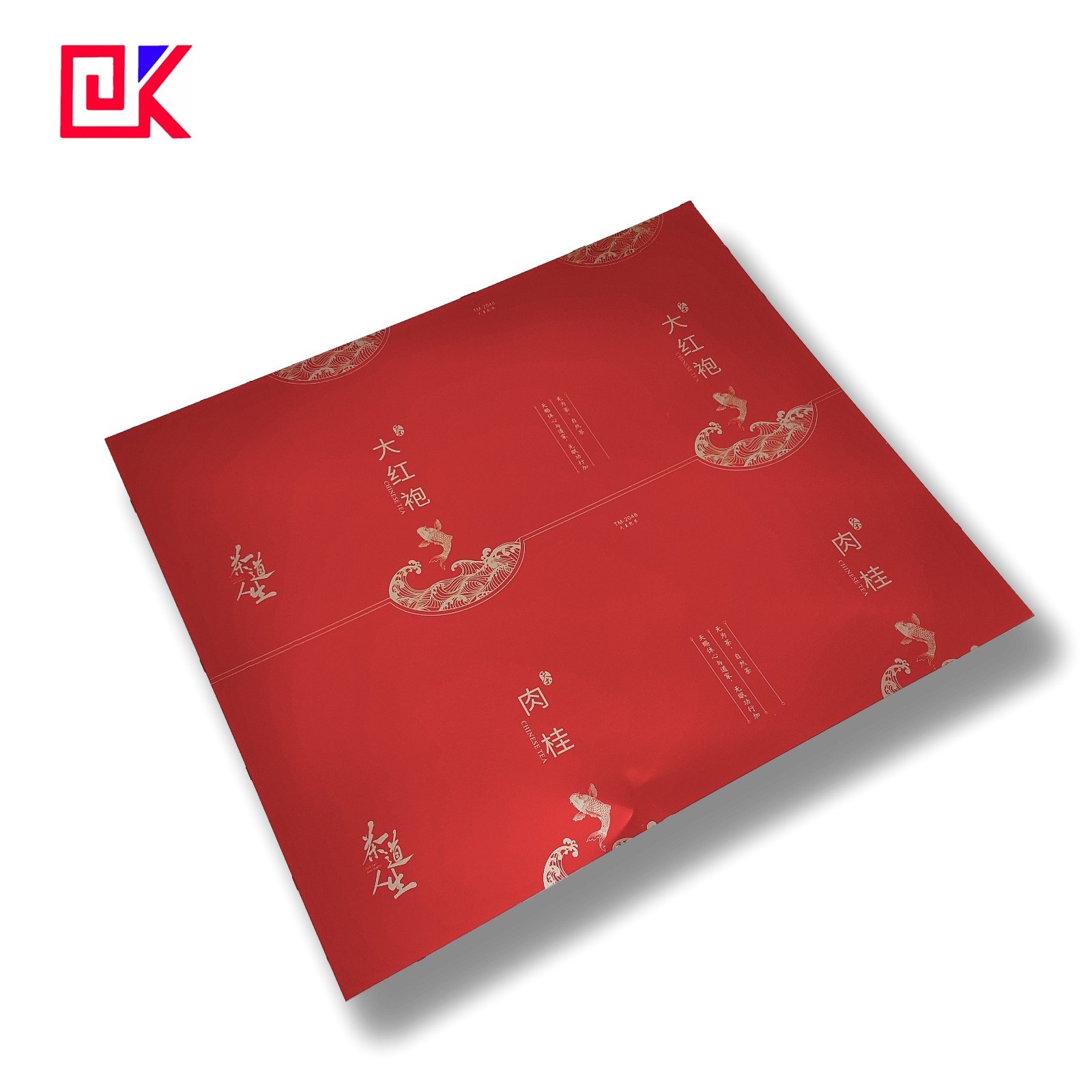

Tinplate For Tea Can

Tinplate Printing

Printing Detail

Printed Tinplate

Outside Printing

All of our products support customization, if you need please feel free to contact us.

Tin coating weight on tinplate:

Classification | Designation of | Nominal tin (g/m2) | Min average (g/m2) | Remark |

Equai tin coating(E) | 1.1/1.1 | 1.1/1.1 | 1.8 | All specification |

2.2/2.2 | 2.2/2.2 | 4.0 | All specification | |

2.8/2.8 | 2.8/2.8 | 5.0 | All specification | |

5.6/5.6 | 5.6/5.6 | 10.5 | All specification | |

classification | 2.2/1.1 | 2.2/1.1 | 2.0/0.9 | All specification |

2.8/1.1 | 2.8/1.1 | 2.25/0.9 | All specification | |

5.6/1.1 | 5.6/1.1 | 5.05/0.9 | All specification | |

2.8/2.2 | 2.8/2.2 | 2.25/2.0 | All specification | |

5.6/2.2 | 5.6/2.2 | 5.05/2.0 | All specification | |

5.6/2.8 | 5.6/2.8 | 5.05/2.25 | All specification |

Surface state on tinplate:

Marks | Suface state | Characteristics |

B | Bright rough | Glazed surface obtained after melting treatment of electroninned smooth raw material strip featuring certain oriented rubstone figure. |

R | Stone rough | Glazed surface obtained after melting treatment of electroninned raw material strip featuring certain oriented rubstone figure. |

S | Silver rough | Glazed surface obtained after melting treatment of electroninned raw material strip with rough matt surface. |

Quality assurance:

1) The Right Material, First Time: Quality is the hallmark of our reputation.

2) Strict quality control,ensure any product satisfied with yours application .

3) Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department

Our advantage:

1). Our product quality is strictly guaranteed!

2). We can provide best service!

3). Our price is competitive!

4). We have more than 10,000 tons in stock so that can

Arrange production schedule immediately for customers.

5). We can do good payment terms.

Our serives:

Features of metal tin sheet printing:

① Colorful and rich in layers. The surface of the metal sheet (iron sheet) of the metal printing substrate is coated with a layer of tin element. The tin-plated thin steel plate is called "tinplate". The tin layer element on the tinplate surface has a glittering metallic color, and then prints the bottom layer (underlay) with transparent or opaque ink, and the pictures are more vivid. If the color of the background ink is selected well, it can reflect the special flash color and improve the contrast of graphics. This is difficult for general packaging products to achieve.

②Improve the artistic appearance of packaging products. Metal printing products can be processed into a variety of three-dimensional packaging, such as round, square, polygonal, curved, tapered, and various other special-shaped cylinders, cans, boxes and packaging appliances, to beautify the goods and improve the competitiveness of goods purpose.

③ The use value is high. Metal printing ink has good abrasion resistance, and is made into various metal packaging and decoration products. It has high use value in daily use and good economic benefits.

The development of metal printing

Metal printing originally used manual lithography to grind bulky stones flat as a printing plate. For each printing plate, the graphics on the surface of the stone were ground away, and then another printing plate was made. The rhyme used is a monochromatic flatbed printing machine with simple process and slow speed.

With the development of lithographic printing technology, metal printing technology has also developed rapidly. Metal printing plates not only use metal plates, but also use photo separation and electronic separation. Fast, high quality, rich picture layers. The printing machine has been developed to the current single-color printing machine and multi-color printing machine, and printing and drying are completed automatically, which greatly reduces the labor intensity of workers.