Specification of Offset Printing Tinplate With UV Curing Inks:

Product name | Offset Printing Tinplate With UV Curing Inks |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.15~0.45mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

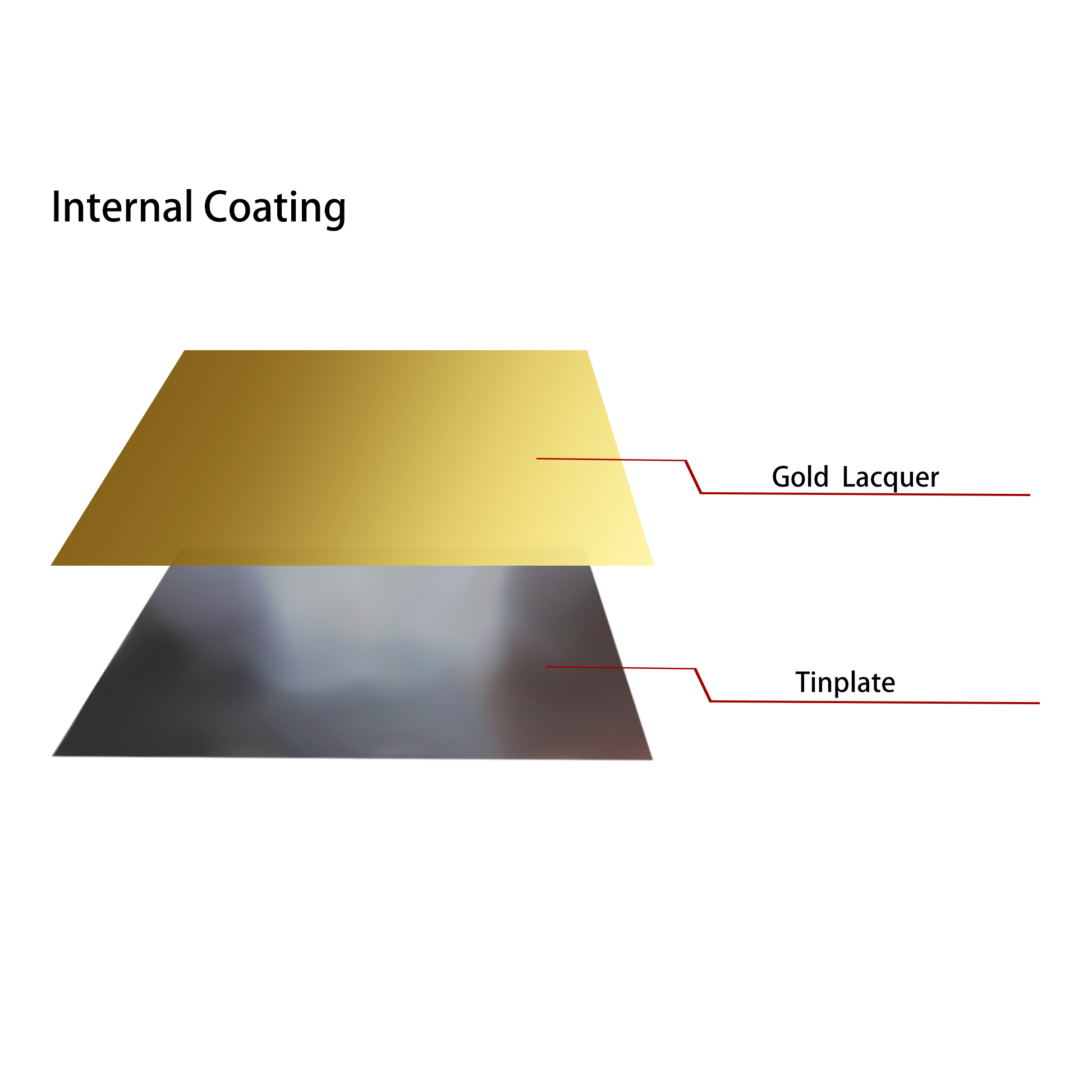

Internal coating | White coation or Gold lacquer |

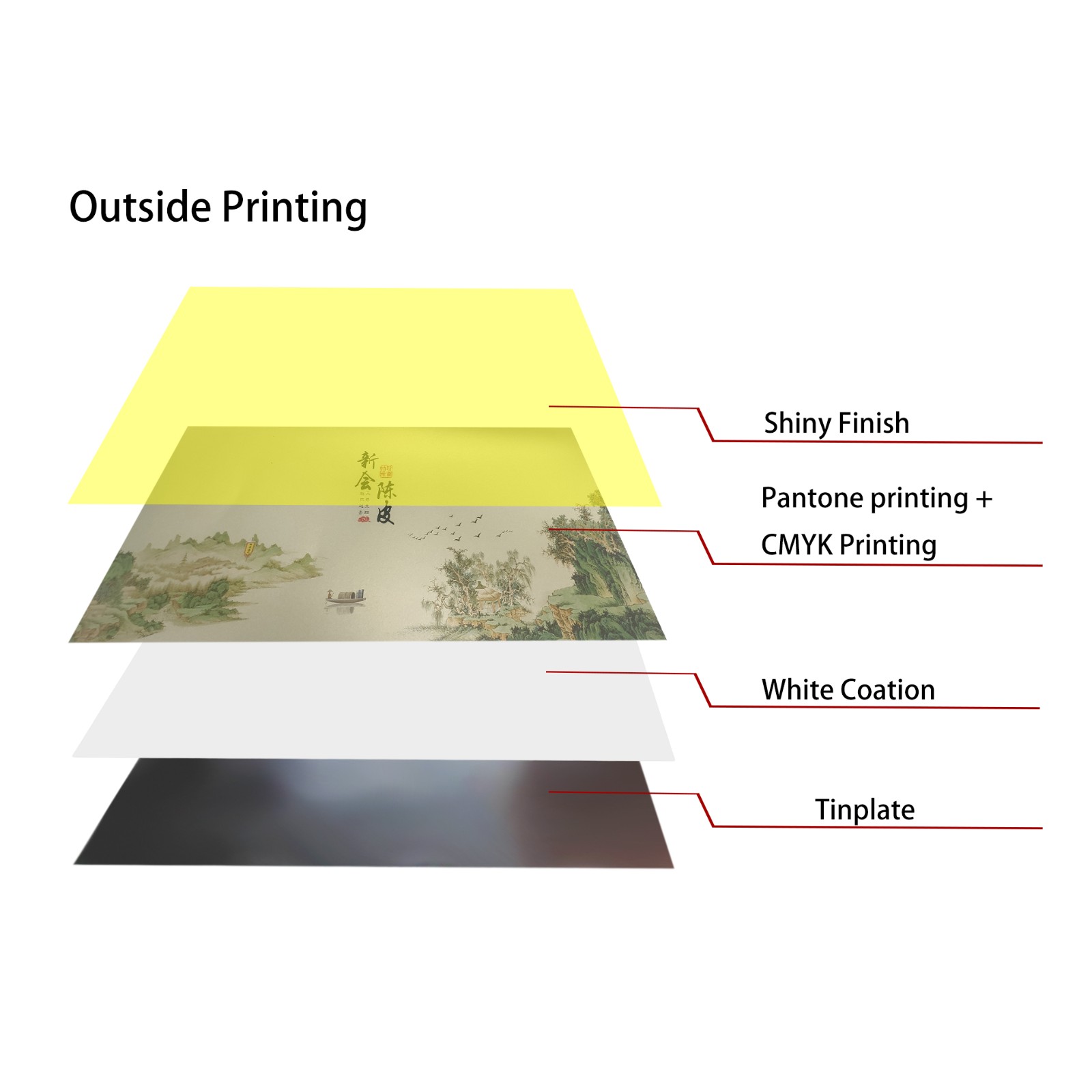

Outside printing | White coation+CMYK Printing+transparency lacquer |

Application | For any packing Box, Can, Bucket, etc(Food, oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

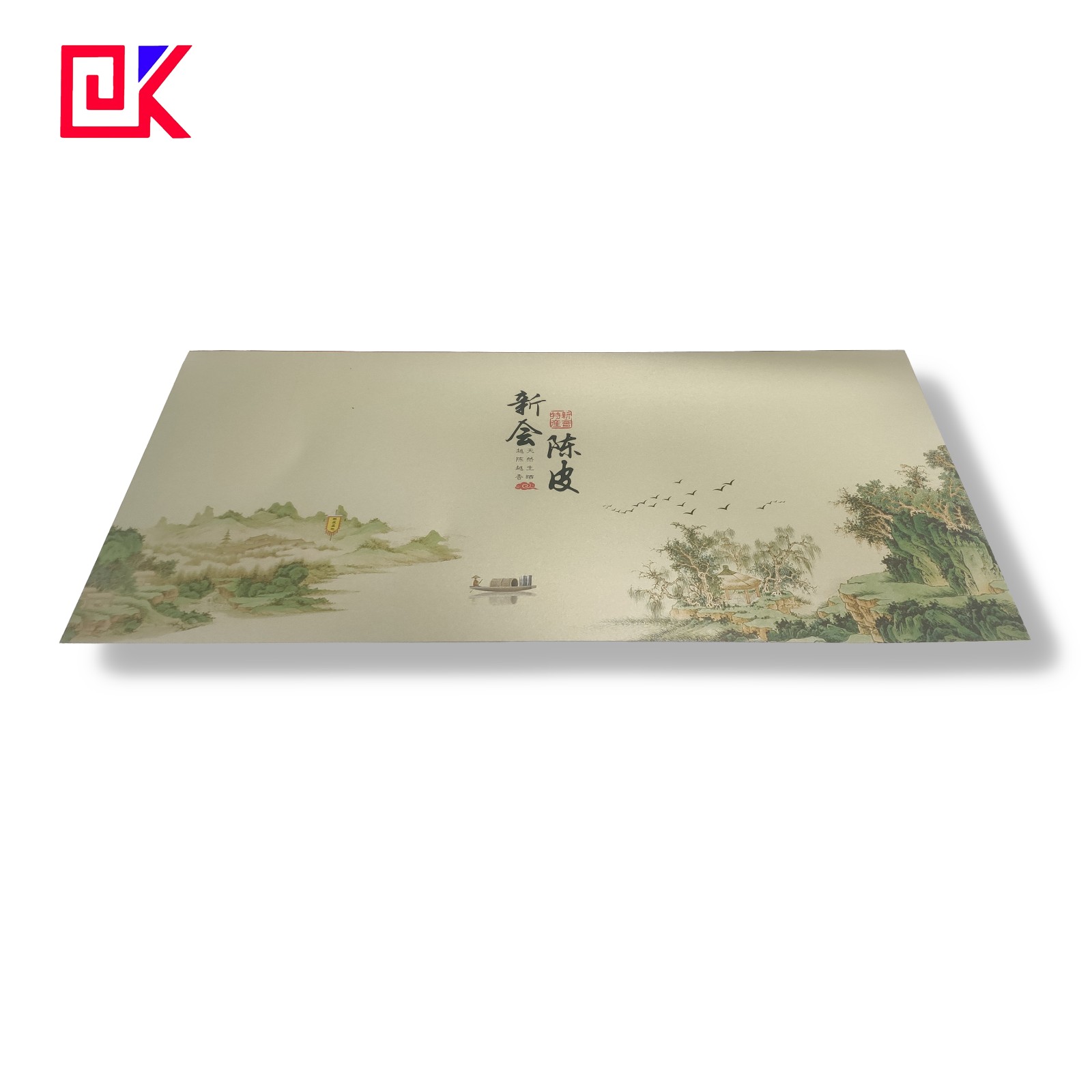

Product Design

Uv Curable printing

Product Design

Outside Printing

Internal Printing

All of our products support customization, if you need please feel free to contact us.

Tin coating weight on tinplate:

Classification | Designation of | Nominal tin (g/m2) | Min average (g/m2) | Remark |

Equai tin coating(E) | 1.1/1.1 | 1.1/1.1 | 1.8 | All specification |

2.2/2.2 | 2.2/2.2 | 4.0 | All specification | |

2.8/2.8 | 2.8/2.8 | 5.0 | All specification | |

5.6/5.6 | 5.6/5.6 | 10.5 | All specification | |

classification | 2.2/1.1 | 2.2/1.1 | 2.0/0.9 | All specification |

2.8/1.1 | 2.8/1.1 | 2.25/0.9 | All specification | |

5.6/1.1 | 5.6/1.1 | 5.05/0.9 | All specification | |

2.8/2.2 | 2.8/2.2 | 2.25/2.0 | All specification | |

5.6/2.2 | 5.6/2.2 | 5.05/2.0 | All specification | |

5.6/2.8 | 5.6/2.8 | 5.05/2.25 | All specification |

Surface state on tinplate:

Marks | Suface state | Characteristics |

B | Bright rough | Glazed surface obtained after melting treatment of electroninned smooth raw material strip featuring certain oriented rubstone figure. |

R | Stone rough | Glazed surface obtained after melting treatment of electroninned raw material strip featuring certain oriented rubstone figure. |

S | Silver rough | Glazed surface obtained after melting treatment of electroninned raw material strip with rough matt surface. |

What is tinplate offset printing?

Offset printing is currently the most common and commonly used printing method for iron box printing. At present, most of the iron printing machines use flat offset printing for tinplate printing processing. Because the printing format of the iron printing machine is not fixed, its application will be limited to a certain extent. With the development of technology, this tinplate offset printing press is also constantly improved. At present, tinplate offset presses that can change the printing format have been successfully developed. After improvement and installation of some parts, it can be used for brushing iron materials and printing UV prints.

Characteristics of tinplate offset printing

1. Tinplate printing belongs to offset printing, but compared with general offset printing, it has its own characteristics:

2. The substrates for tinplate printing are various metal sheets. At present, the substrates used for tinplate printing are tin-plated sheet steel (tinplate), chrome-plated sheet steel, ordinary sheet steel, and aluminum alloy sheet. These metal sheets of iron box manufacturers can be divided into three types: hard iron sheet, neutral iron sheet and soft iron sheet according to their different hardness. Aluminum alloy sheet is soft, ordinary sheet steel is neutral, and chrome-plated sheet steel is rigid. During the printing process, depending on the hardness of the substrate, adjust the pressure of the cylinder and select the appropriate lining material.

3. For use in cans, it is required that the printed iron ink is resistant to high temperature and cooking, and is non-toxic and harmless.

4. The printing operation is different from a coating which plays a decisive role in the quality of iron sheet printing. The coating can increase the adhesion between the iron sheet and the ink layer and protect the cure ink film layer.

5. Use special printing ink. As the tinplate printed substrates have smooth surfaces and do not have the ability to absorb, tinplate printing inks rely on oxidized conjunctiva and volatile drying. At the same time, tinplate prints generally require offset printing. When manufacturing the printing machine, the blowing force of the blowing nozzle and the suction force of the suction nozzle must be considered, and a horseshoe-shaped magnet is added at the feed to overcome the adsorption force between the iron plates. During the operation, the air volume of the mouthpiece and the suction nozzle should be adjusted according to different weight substrates. The adjustment of the drum pressure is the key to the operation. In addition to adjusting the thickness of the substrate, you must also consider the transfer of the dots.

Production capability:

1). Our company have two factories:one is tinplate coating and printing, and the other is tin can making , can supply one-stop service from plain tinplate, coated tinplate ,printed tinplate ,lacquered tinplate till the final tin cans.

2). Smooth production ability 4,000tons each month .

3). OEM/ODM , Free of charges of Logo design and printing on your goods

Packing of printing tinplate:

For tinplate coil: Anti-rust paper+Metal cover+Corner cap protected+Wood skids.

For tinplate sheet: Thin plastic film+Anti-rust paper+Metal cover+Metal corner cap protected+Binding strap+Pallet.

Product Title

Product Title

Product Title

Loading by 20 feet container: 20~25 tons

Main markets:

Our products are mainly exported to USA, Egypt, UK, Russia, Germany, Myanmar, Canada, Malaysia, Argentina, Peru, Colombia, Saudi Arabia, UAE, and so on