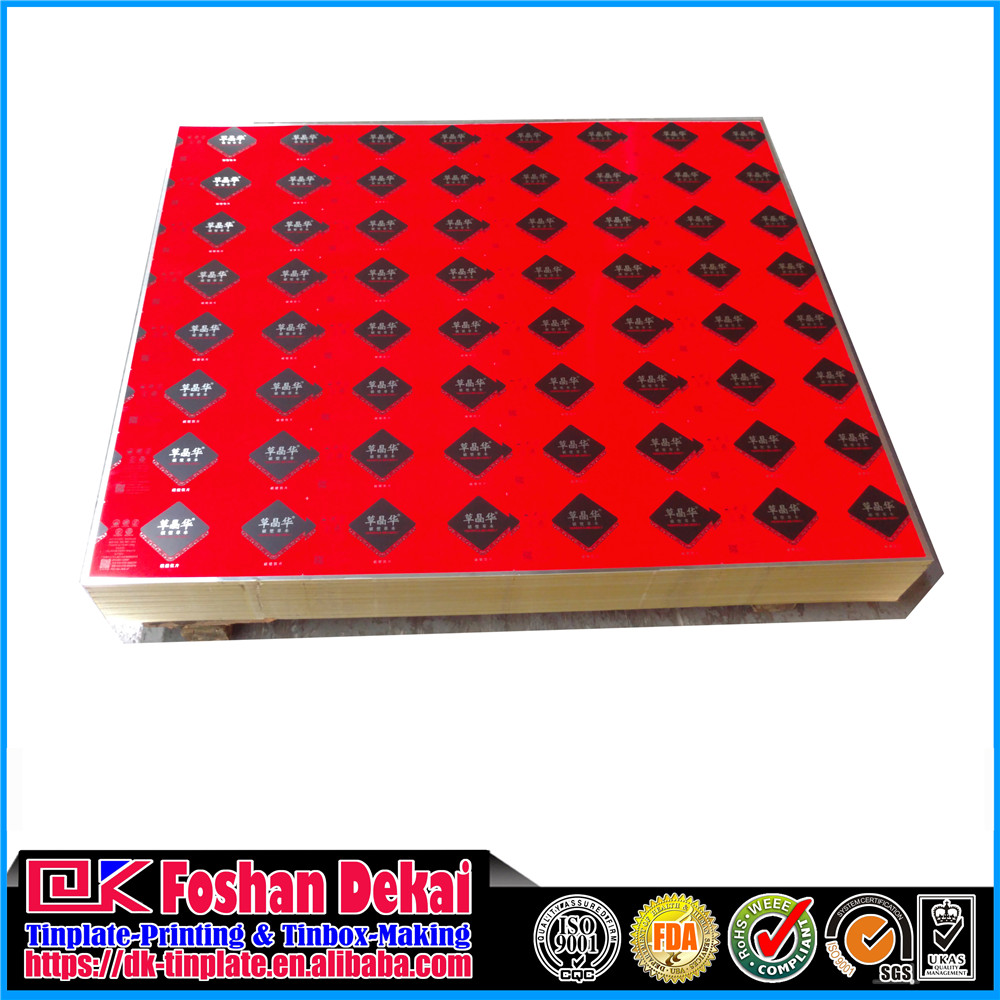

Specification of Color Printing Tinplate For Beverage Tins:

Product name | Color Printing Tinplate For Beverage Cans |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.18~0.23mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

Internal coating | White coation or Gold lacquer |

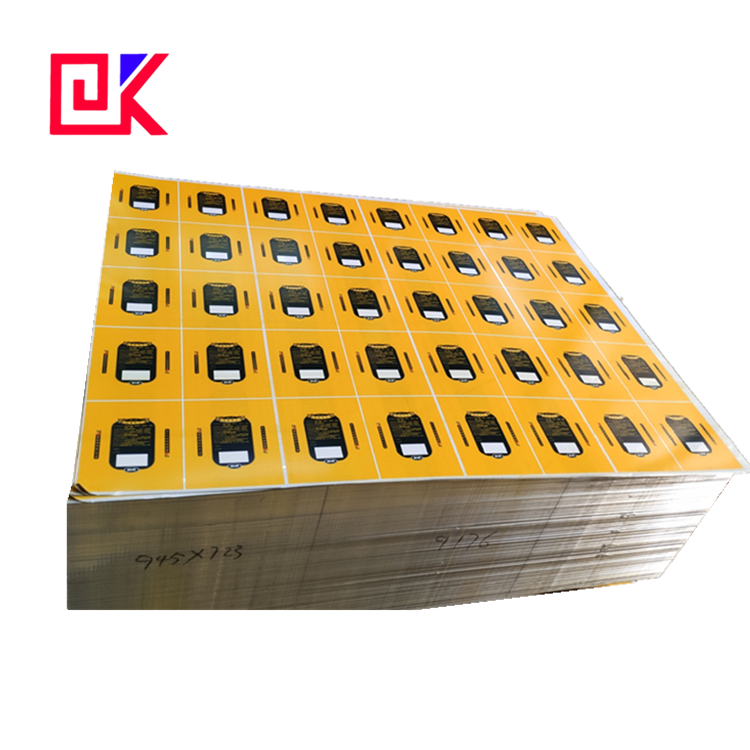

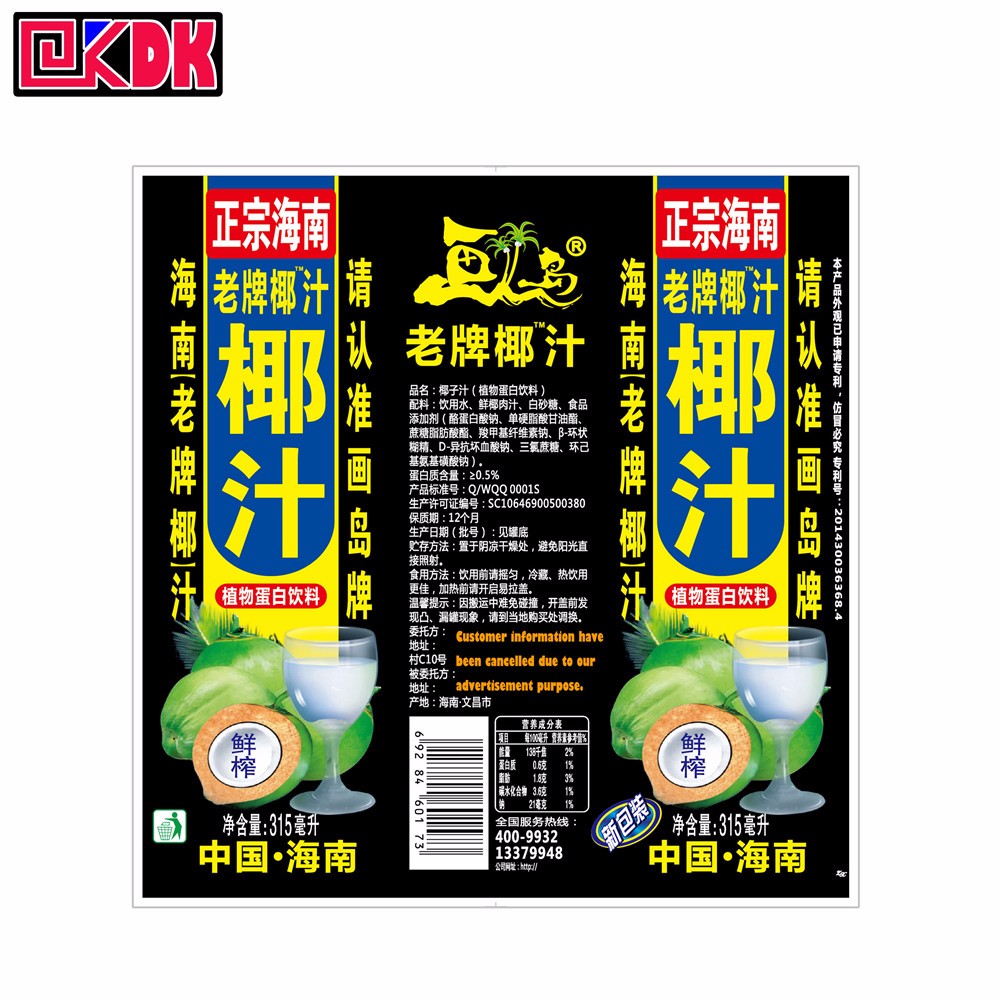

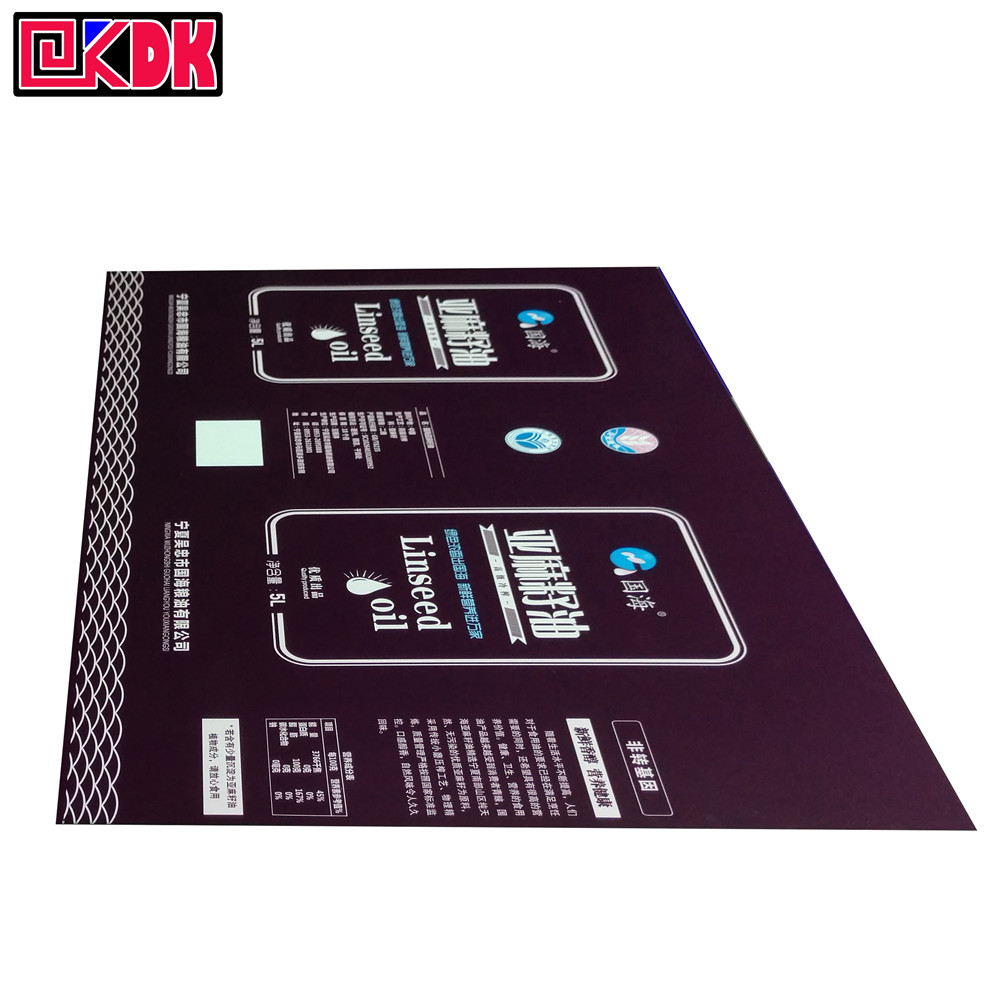

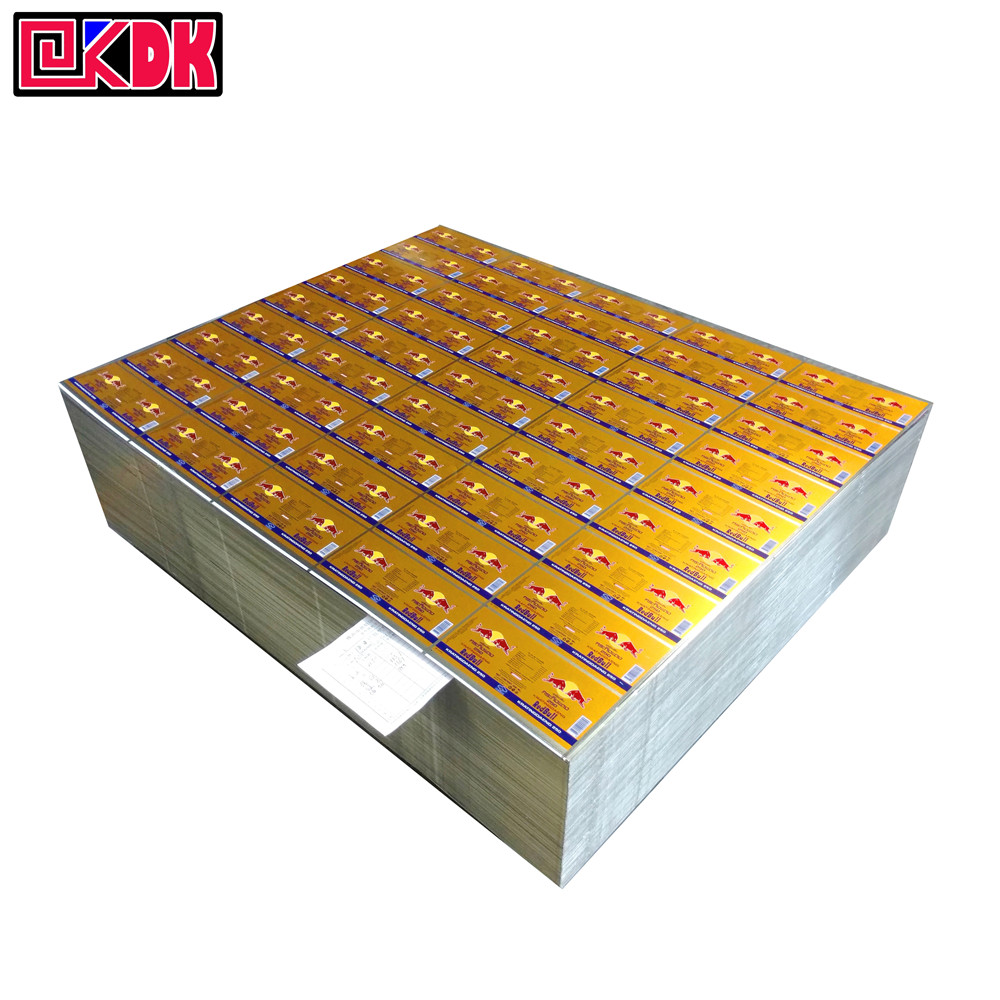

Outside printing | White coation+CMYK Printing+transparency lacquer |

Application | For any packing Tin, Box, Can, Bucket, etc(Beverage,Food, oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

Standard of tinplate temper:

Standard Material | Q/BQB 455-2009 | JIS G3315-2008 | ASTM A623M-08 | EM 10202:1989 | EN 1020:2001 | ISO 11950:1995 |

Single Reduce | - | T-1 | T-1(49) | T50 | TS230 | TH50+CE |

T-1.5 | - | - | - | - | - | |

T-2 | T-2 | T-2(T53) | T52 | TS245 | TH52+CE | |

T-2.5 | T-2.5 | - | - | TS260 | TH55+CE | |

T-3 | T-3 | T-3(T57) | T57 | TS275 | TH57+CE | |

T-3.5 | - | - | - | TS290 | - | |

T-4 | T-4 | T-4(T61) | T61 | TH415 | TH61+CE | |

T-5 | T-5 | T-5(T65) | T65 | TH435 | TH65+CE | |

Double Reduce | DR-7M | - | DR-7.5 | - | TH520 | - |

DR-8 | LR-8 | DR-8 | DR550 | TH550 | TH550+CE | |

DR-8M | - | DR-8.5 | - | TH580 | TH580+CE | |

DR-9 | DR-9 | DR-9 | DR620 | TH620 | TH620+CE | |

DR-9M | DR-9M | DR-9.5 | DR-660 | - | TH660+CE | |

DR-10 | DR-10 | - | - | - | TH690+CE |

Surface state of tinplate:

Marks | Suface state | Characteristics |

B | Bright rough | Glazed surface obtained after melting treatment of electroninned smooth raw material strip featuring certain oriented rubstone figure. |

R | Stone rough | Glazed surface obtained after melting treatment of electroninned raw material strip featuring certain oriented rubstone figure. |

S | Silver rough | Glazed surface obtained after melting treatment of electroninned raw material strip with rough matt surface. |

Tinplate raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of tinplate can be extracted from 1.8 ton of iron ore

Application of tinplate printing:

(1) In the packaging industry. Because tinplate products have the characteristics of sturdiness and durability, especially the finished foods, such as cans and boxes, have a long storage time and good freshness. If they are exquisitely shaped and designed with high-end color printing, they can not only increase the added value of the product, Improve economic efficiency, but also has valuable treasure value.

(2) in children's toys. Because tinplate has excellent ductility, it can be made into a variety of toy products with a certain process design and printing, which increases the fun of children.

(3) In terms of advertising and decoration. The printing of large metal advertising pictures, posters and various decorative steel plates can beautify the environment.

(4) In terms of culture and gifts. Print various colors of aluminum foil decoration, packaging gifts and metal stationery, such as office supplies such as folders, stationery boxes, file cabinets.

(5) in other respects. Printing of various other tinplate products.

Quality assurance:

1) The Right Material, First Time: Quality is the hallmark of our reputation.

2) Strict quality control,ensure any product satisfied with yours application .

3) Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department

Production capability:

1). Our company have two factories:one is tinplate coating and printing, and the other is tin can making , can supply one-stop service from plain tinplate, coated tinplate ,printed tinplate ,lacquered tinplate till the final tin cans.

2). Smooth production ability 4,000tons each month .

3). OEM/ODM , Free of charges of Logo design and printing on your goods .