Specification of Food Grade Tin Plate For Making Cigarette Tins (tobacco tins):

Thickness | 0.18~0.23mm |

Width | 700~1200mm |

Material | MR SPCC |

Tin Coating | 1.1/1.1, 2.8/2.8/,5.6/5.6 |

Temper | T1~T6/DR7~DR10 |

Coil Weight | 3~10 MT |

Oiling | DOS |

Surface Finish | Bright, Stone, Silver, Matt |

Annealing | CA, BA |

Packing | Wrapped completely with an inner cover of plastic or water proof papers with corners pertected |

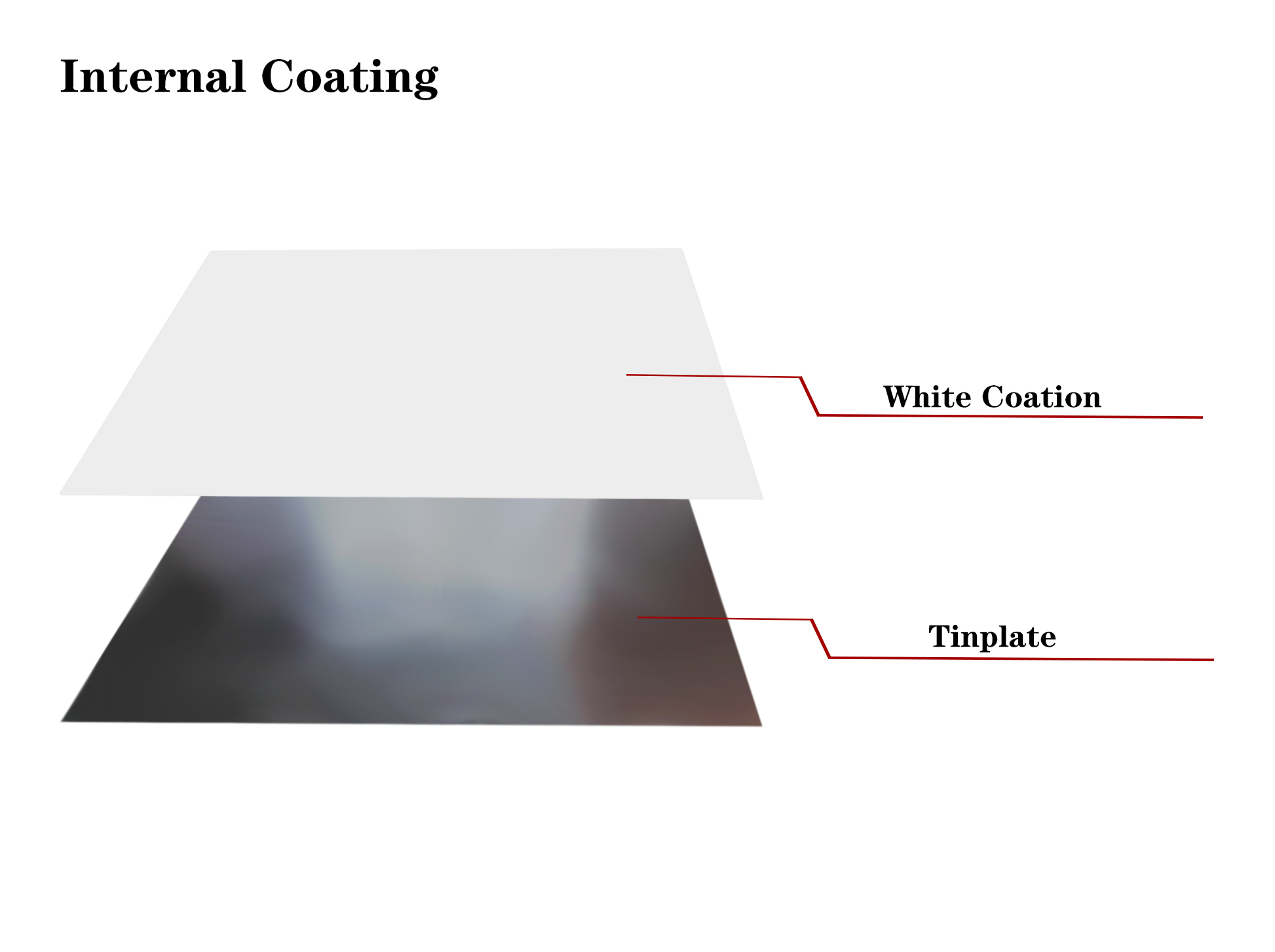

Tin coating amount. The amount of tin plating is an indicator of the thickness of the tin layer. It is expressed in terms of the amount of tin plating per unit area (g / m2). Generally, the larger the amount of tin plating, the thicker the tin layer, and the better the corrosion resistance.

Tinplate Status | Coating Status | Former Coat | Coating W. Code | Normal C-W | Min. Ave. C-W | Remarks |

EPT | Equally Coating (E) | 10# | 1.1/1.1 | 1.1/1.1 | 0.9/0.9 | All specifications |

20# | 2.2/2.2 | 2.2/2.2 | 1.8/1.8 | |||

25# | 2.8/2.8 | 2.8/2.8 | 2.5/2.5 | |||

50# | 5.6/5.6 | 5.6/5.6 | 5.2/5.2 | |||

75# | 8.4/8.4 | 8.4/8.4 | 7.8/7.8 | |||

100# | 11.2/11.2 | 11.2/11.2 | 10.1/10.1 | |||

Classified Coat (D/A) | 25#/10# | 2.8/1.1 | 2.8/1.1 | 2.5/0.9 | ||

50#/10# | 5.6/1.1 | 5.6/1.1 | 5.2/0.9 | |||

50#/25# | 5.6/2.8 | 5.6/2.8 | 5.2/2.5 | |||

75#/25# | 8.4/2.8 | 8.4/2.8 | 7.8/2.5 | |||

75#/50# | 8.4/5.6 | 8.4/5.6 | 7.8/5.2 | |||

100#/25# | 11.2/2.8 | 11.2/2.8 | 10.1/2.5 | |||

100#/50# | 11.2/5.6 | 11.2/5.6 | 10.1/5.2 | |||

100#/75# | 11.2/8.4 | 11.2/8.4 | 10.1/7.8 |

Tin plate surface finish:

Surface finishing is distinguished by the structural texture of the steel substrate and whether the coating is reflowed. Tinplate can be made into four different effects such as shiny surface, stone surface, silver surface, and matte surface, among which the most widely used are shiny surface and stone surface.

Marks | Suface state | Characteristics |

B | Bright rough | Glazed surface obtained after melting treatment of electroninned smooth raw material strip featuring certain oriented rubstone figure. |

R | Stone rough | Glazed surface obtained after melting treatment of electroninned raw material strip featuring certain oriented rubstone figure. |

S | Silver rough | Glazed surface obtained after melting treatment of electroninned raw material strip with rough matt surface. |

Tin plate Packaging & Loading:

Packaging for tinplate coil: Anti-rust paper+Metal cover+Corner cap protected+Wood skids.

Packaging for tinplate sheet: Thin plastic film+Anti-rust paper+Metal cover+Metal corner cap protected+Binding strap+Pallet.

Loading by 20 feet container: about 20~25 tons

Characteristics of tinplate:

Tin plate is a complex technology product, which can be explained from the many technical indicators that are tested when it leaves the factory ::

1. Analysis and inspection of steel-based components, including: carbon, copper, chromium, molybdenum, nickel, silicon (Si), manganese (M n), phosphorus (P), sulfur (S) and other residual elements Analysis, and determination of other metal and non-metallic inclusions;

2. Metallographic examination: 5 items including the structure inspection, cementite, purity, grain size, and alloy layer structural inspection;

3. Mechanical property inspection: 8 items including hardness, cup protrusion value (recommended instrument: cup protrusion tester), tensile force, rebound, aging, bending, roughness, and thickness;

4.Corrosion resistance (intrinsic quality) test: including the measurement of tin layer thickness, alloy layer thickness, oxide layer, passivation layer, oil film amount, ATC (alloy tin galvanic current), ISV (iron dissolution value), P LV (acid leaching time lag), TCS (grain size), anti-vulcanization, weldability, adhesion, sanitary inspection and other 13 items;

5. Thin plate shape inspection: 5 inspections such as right angle, sickle bend, side wave, medium wave, warpage, etc.

There are a total of 40 inspections above. When the products leave the factory, they must be carried out at different frequencies. It can be seen that the quality of tinplate exceeds the general imagination.