Food Packaging Grade Electrolytic Tinplate:

Thickness | 0.20~0.28mm |

Width | 700~1200mm |

Material | MR SPCC |

Tin Coating | 1.1/1.1, 2.8/2.8/,5.6/5.6 |

Temper | T1~T6/DR7~DR10 |

Coil Weight | 3~10 MT |

Oiling | DOS |

Surface Finish | Bright, Stone, Silver, Matt |

Annealing | CA, BA |

Packing | Wrapped completely with an inner cover of plastic or water proof papers with corners pertected |

| Application | food containers |

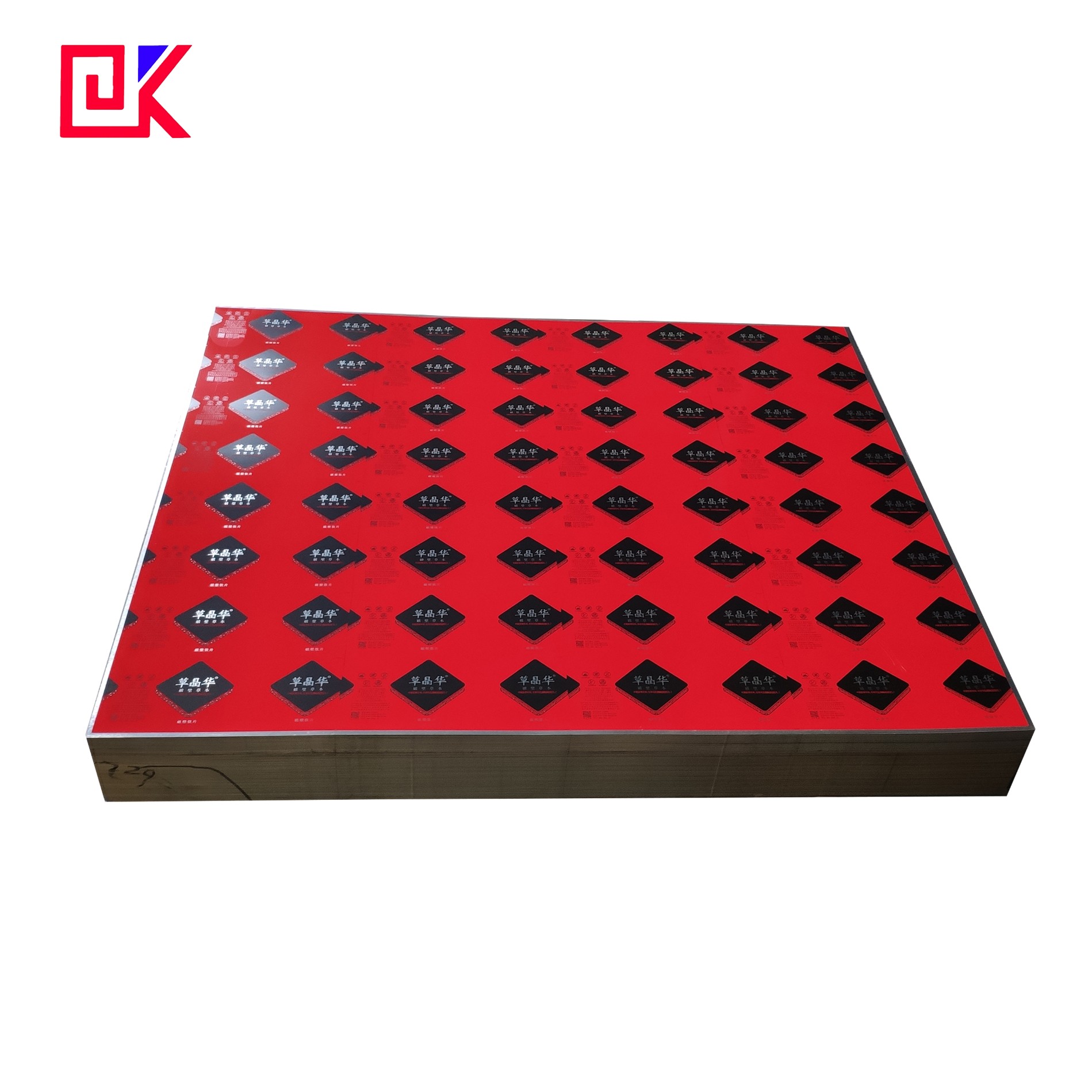

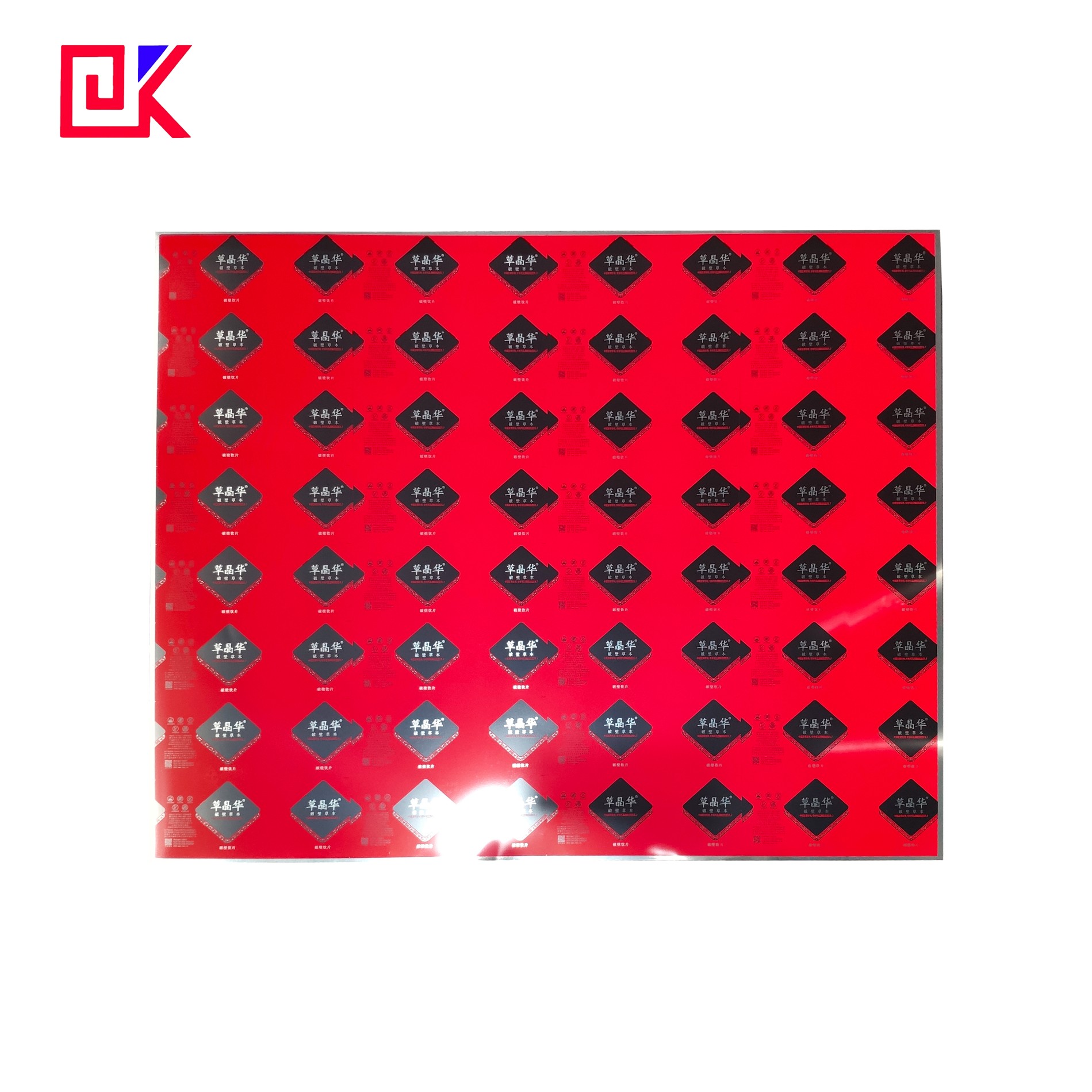

Red Coating Tinplate Product Show

food tin Printing Detail

Composition of tinplate:

Tinplate is mainly composed of five parts: steel substrate, tin-iron alloy layer, tin layer, oxide film and oil film. The thickness, composition and performance of each part are shown in Table 1.

Table 1: Thickness, composition and properties of each part of tinplate:

Name | thickness | composition | properties |

oil film | 2~5mg/cm² | Cottonseed oil or malonic acid diester | Lubrication and rust prevention |

oxide film | 1~3mg/cm² (Single-side coating) | Ferrous oxide, tin oxide, chromium oxide, metallic chromium | After chemical treatment, it has the functions of anti-rust, discoloration and anti-sulfide |

tin layer | 5.6~22.4mg/cm² | Pure tin | Beautiful, easy to weld, corrosion-resistant and non-toxic |

tin-iron alloy layer | <1g/cm² | Tin-iron alloy crystals | Corrosion resistance, but too thick for poor processability and solderability |

steel substrate | 0.2~0.3mm | Low-carbon steel | Good processing performance, with certain strength after can making |

Corrosion resistance:

Corrosion resistance is the most important property of tin plate. The acid leaching time lag value, iron dissolution value, tin plating grain size, alloy-tin galvanic value, and tin layer thickness are collectively referred to as the five corrosion resistance indicators of the tinplate. The comprehensive evaluation of the five indicators should be used to comprehensively measure the plating Corrosion resistance of tin plate

How to choose tinplate:

When selecting tinplate, the requirements of the type of product (beverage can,aerosol can, milk powder can, battery iron, etc.) and the parts of the product (bottom cover, top cover, can body, etc.) should be considered at the same time ,please refer to Table for the selection method of tinplate.

Our advantage:

1). Our product quality is strictly guaranteed!

2). We can provide best service!

3). Our price is competitive!

4). We have more than 10,000 tons in stock so that can

Arrange production schedule immediately for customers.

5). We can do good payment terms.

Our serives:

1. Global marketing strategy: home sales will account for about 65% of the output and foreign sales for 35%.

2. Senior experts on tin plate will provide professional support.

3. Free tinplate samples will be supplied.

4. Color: based on customers' requirments (if you have pictures, can send to me)

5. We have the latest detection equipments and our own specialist laboratories.

What is Electrolytic Tinplate?

Tinplate, also known as tin-plated iron, is a common name for electroplated tin thin steel plates, with the English abbreviation SPTE, which refers to cold-rolled low-carbon thin steel plates or strips coated with commercial pure tin on both sides. Tin is mainly used to prevent corrosion and rust. It combines the strength and formability of steel with the corrosion resistance, solderability, and aesthetic appearance of steel in one material. It has the characteristics of corrosion resistance, non-toxicity, high strength, and good ductility.

National Electrolytic Tinplate standards:

In addition to the United States, the contents of tinplate standards in various countries (including ISO standards) are becoming more and more consistent.

(1) All are defined as low-carbon cold with a thickness of 0.14-0.49mm

Rolled tin plate is called cold rolled electroplated tin sheet, which is commonly known as tinplate;

(2) It is required to use Grade A tin with a purity of 99.85% or more as one of the raw materials;

(3) All specified dimensional tolerances are -0, + 3mm;

(4) The maximum allowable thickness tolerances and plate shape deviations (such as cut slope, side wave, medium wave, warpage, etc.) are specified;

(5) It is stipulated that the qualified products can be printed and coated on the entire board;

(6) A uniform tin plating step and the corresponding minimum tin plating are specified. That is: rung: 1.1, 1.7 (1.5), 2.2 (2.0), 2 .8, (4.0), (5.0), 5 .6, 8 .4, 11.2g / m2 and corresponding minimum allowable values;

(7) All stipulate uniform measurement and testing methods (test surface Rockwell hardness HR30T or HR15T), and their classification and marking methods, such as T 52, T 54, T 57, T 61, T 64 , DR8, DR9, DR9M, etc.