Specification of tin printing:

Product name | Full Color Printing Tinplate For Coffee Tins |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tin plate sheet/Tinplate sheet (MR SPCC) |

Steel type | MR grade for food packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T3,T4 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.19~0.23mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

Internal coating | Gold lacquer+Aluminum paste+transparency lacquer |

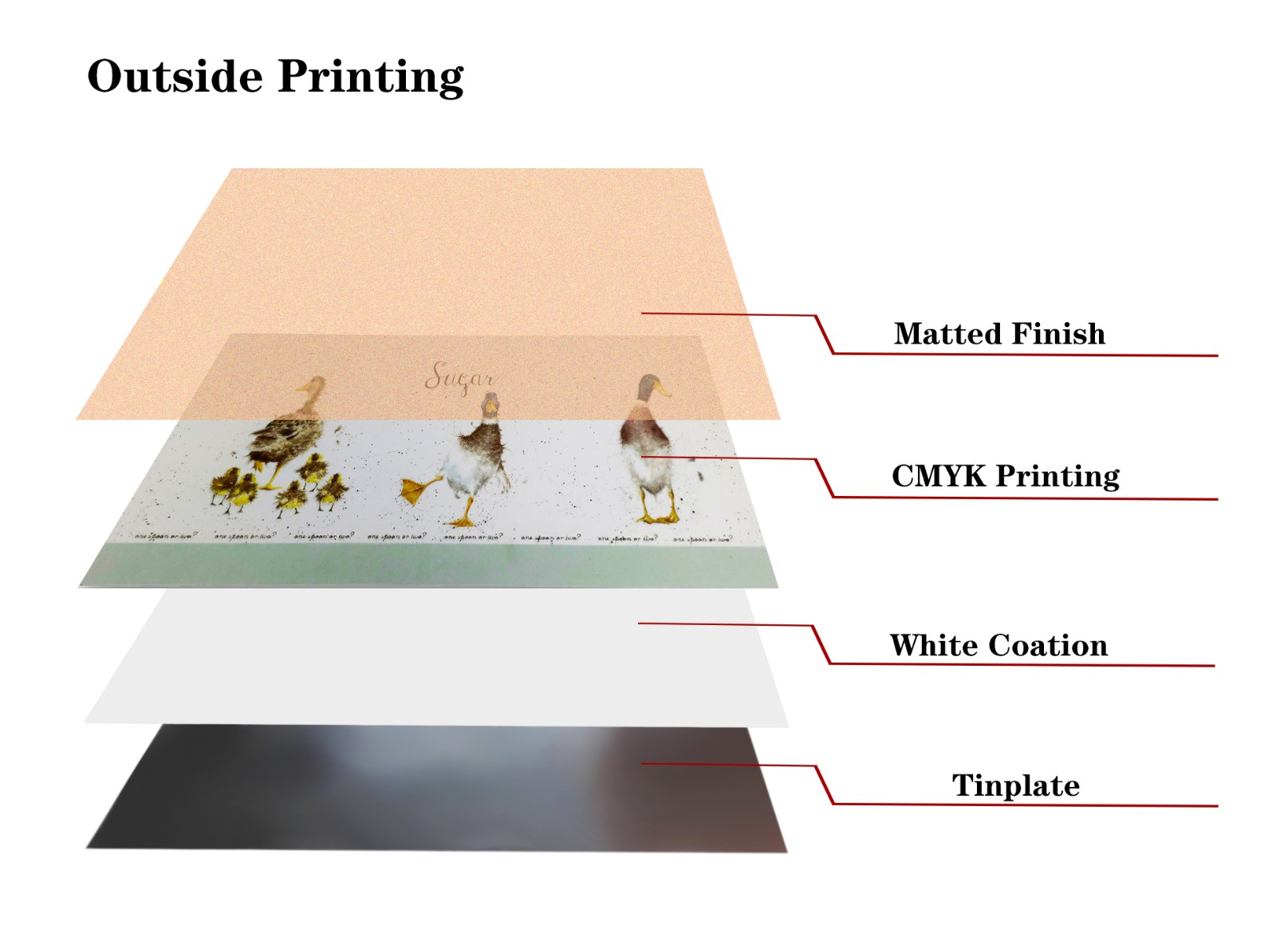

Outside printing | White coation+CMYK Printing+Shinny Finish |

Application | For any packing Tin, Box, Can, Bucket, etc(Food, coffee can,oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

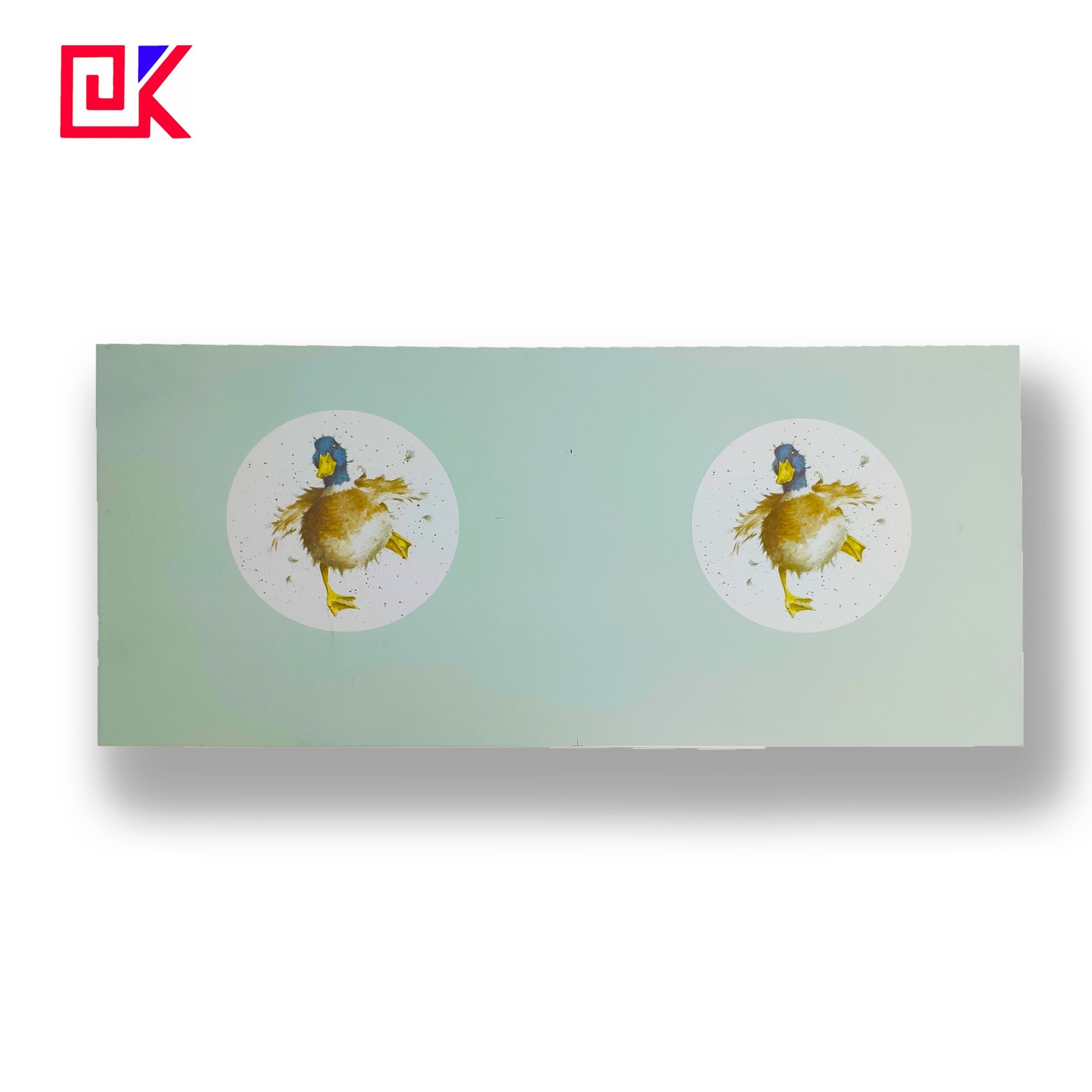

Product Show

Printing Show

Printing Detail

Printing Detail

Outside Printing

All of our products support customization, if you need please feel free to contact us.

Standard of tinplate temper:

Standard Material | Q/BQB 455-2009 | JIS G3315-2008 | ASTM A623M-08 | EM 10202:1989 | EN 1020:2001 | ISO 11950:1995 |

Single Reduce | - | T-1 | T-1(49) | T50 | TS230 | TH50+CE |

T-1.5 | - | - | - | - | - | |

T-2 | T-2 | T-2(T53) | T52 | TS245 | TH52+CE | |

T-2.5 | T-2.5 | - | - | TS260 | TH55+CE | |

T-3 | T-3 | T-3(T57) | T57 | TS275 | TH57+CE | |

T-3.5 | - | - | - | TS290 | - | |

T-4 | T-4 | T-4(T61) | T61 | TH415 | TH61+CE | |

T-5 | T-5 | T-5(T65) | T65 | TH435 | TH65+CE | |

Double Reduce | DR-7M | - | DR-7.5 | - | TH520 | - |

DR-8 | LR-8 | DR-8 | DR550 | TH550 | TH550+CE | |

DR-8M | - | DR-8.5 | - | TH580 | TH580+CE | |

DR-9 | DR-9 | DR-9 | DR620 | TH620 | TH620+CE | |

DR-9M | DR-9M | DR-9.5 | DR-660 | - | TH660+CE | |

DR-10 | DR-10 | - | - | - | TH690+CE |

Tin coating on tinplate:

Tinplate Status | Coating Status | Former Coat | Coating W. Code | Normal C-W | Min. Ave. C-W | Remarks |

EPT | Equally Coating (E) | 10# | 1.1/1.1 | 1.1/1.1 | 0.9/0.9 | All specifications |

20# | 2.2/2.2 | 2.2/2.2 | 1.8/1.8 | |||

25# | 2.8/2.8 | 2.8/2.8 | 2.5/2.5 | |||

50# | 5.6/5.6 | 5.6/5.6 | 5.2/5.2 | |||

75# | 8.4/8.4 | 8.4/8.4 | 7.8/7.8 | |||

100# | 11.2/11.2 | 11.2/11.2 | 10.1/10.1 | |||

Classified Coat (D/A) | 25#/10# | 2.8/1.1 | 2.8/1.1 | 2.5/0.9 | ||

50#/10# | 5.6/1.1 | 5.6/1.1 | 5.2/0.9 | |||

50#/25# | 5.6/2.8 | 5.6/2.8 | 5.2/2.5 | |||

75#/25# | 8.4/2.8 | 8.4/2.8 | 7.8/2.5 | |||

75#/50# | 8.4/5.6 | 8.4/5.6 | 7.8/5.2 | |||

100#/25# | 11.2/2.8 | 11.2/2.8 | 10.1/2.5 | |||

100#/50# | 11.2/5.6 | 11.2/5.6 | 10.1/5.2 | |||

100#/75# | 11.2/8.4 | 11.2/8.4 | 10.1/7.8 |

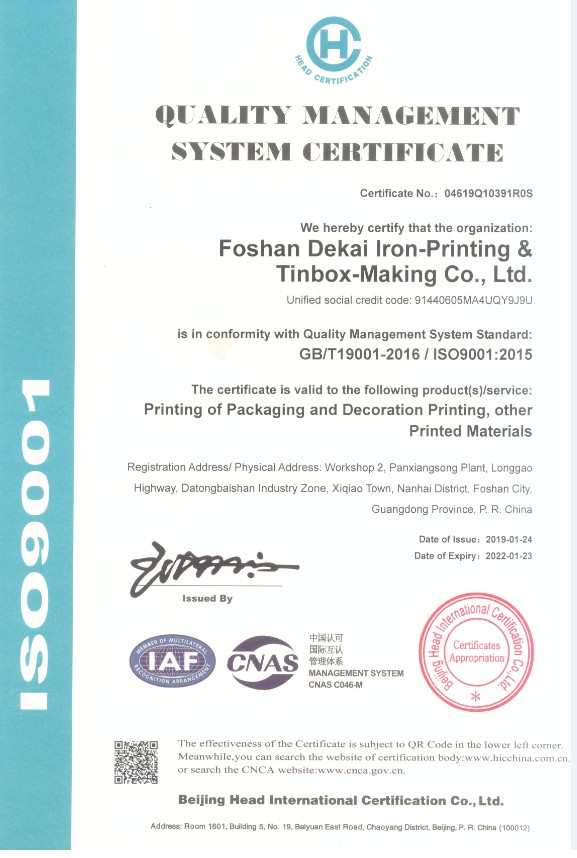

Tin printing product has got the cerfificate: Approved by the ISO 9001

What is tin printing ?

Tin printing belongs to the category of metal printing,is one special printing. Tin printing has its special features in printing technology, printing materials and printing equipment structure.in the principle of imprint transfer, the physical properties of water and ink repel are used, and the printing plate graphic is transferred to tinplate through a blanket by means of printing pressure.

What is process and characteristics of tin printing ?

Due to the special physical and chemical properties of tinplate and the reprocessing performance of tinplate printed matter, its printing process is greatly different from ordinary offset printing.tinplate printing process is as follows:

Coating before printing-Printing-coating after printed-Processing.

1. Requirement for tin plate

The thickness of printed tin plate is usually between 0.18 and 0.45 mm. With the increasing demand for metal tins, the variety of tin plate is also increasing. The main types are CC steel, large-size rough-faced iron, low tin content or chrome plating. The production of these types of tin plate not only reduces the cost of manufacturers and users, but also meets the electricity demand. Welding cans, bonding cans, DRD cans, DI cans and other cans, crown caps, unscrewing caps, etc., are used in the industries of oleochemicals, daily chemicals, canned foods, beverage cans, stationery and cosmetics, etc. Metal tin packaging, provides good packaging materials,

2. Special requirements for printing ink:

(1) Has good adhesion and mechanical properties

Because tin plate printing products are eventually made into food cans, toys, metal photo frames, and barrels and cans of chemical products, they need to be cut, bent, and stretched. Therefore, printing inks are required to have good adhesion to tinplate and corresponding machinery performance. In order to improve the adhesion of the printing ink, the tinplate needs to be white-primed before printing. White is the base color of all pictures and has a very high brightness. After adding other high-energy hue, the brightness of each hue can be increased to form a Color scale.

(2) Requirements for white ink

The tinplate surface is silver-white (or yellow) with metallic luster. Before printing the color graphics, the surface needs to be printed white. Due to the limitation of the ink covering ability, it usually takes 2-3 times to print white, and its whiteness can reach 75%. Whiteness is an important indicator of the quality of printed tinplate products. Printed white ink has a good binding force with the primer, does not turn yellow after high temperature baking, and does not discolor after high temperature resistance. Applying a primer to tinplate can increase the adhesion to tinplate and have a good combination with white ink. force. The commonly used primer is epoxy-amine based, with light color, no yellowing and aging after repeated baking, good flexibility and impact resistance.

(3) Requirements for color ink

Tinplate printing color inks, in addition to having a certain degree of water resistance, also need their special requirements. As the tinplate surface does not penetrate water and solvents, it needs to be baked and dried, so its ink should be heat-curable. The pigment is required to have higher tinting strength and durability. In addition to the basic properties of general offset printing inks, tin printing inks should also have the characteristics of heat resistance, strong ink film adhesion, impact resistance, good rigidity, cooking resistance and light resistance according to the characteristics of printing iron.

(3) CMYK and full colours of the “Pantone” system can be printed, customized colors are available.

(4) Drying process of ink

In the production of printing iron, the drying of the ink is a complicated physical and chemical reaction process. There are many factors that affect drying, so to control the drying speed of the ink and ensure the quality of the product, the physical and chemical mechanism in the ink drying, that is, the factors that affect the drying speed, must be mastered in order to effectively perform the fast iron printing operation. The drying speed of the ink has become the main content of the ink drying. Then, what harm is the ink drying too fast? It can reduce the normal transfer performance of the ink and affect the normal production process; it can cause the print to be dim, the ink color to be faded, and the ink to dry on the surface of the printing plate and the ink roller, which will hinder the lower ink in the transfer; Outer expansion; it can make the ink absorbent increase due to excessive amount of desiccant, and the dirty part will cause dirt. So what harm is the ink drying too slowly? Can cause overprinting difficulties and cause adhesions; can cause poor adhesion and reduced firmness; and can easily cause scratches during transport. Therefore, the drying speed of the ink should be appropriate. Too fast or too slow is disadvantageous.

3. Special structure of printing equipment

Due to the different substrates, the auxiliary structure of the tinplate printer is also different from the offset printing machine. Because tinplate is insoluble in water and does not adsorb solvents, the printing ink needs to be baked at high temperature to cure the solvent volatile conjunctiva. Iron printing process equipment should be equipped with iron printing drying room. Printed iron automatic line is generally about 52 meters in length, which has the characteristics of precision and hugeness. Because the physical properties of tinplate are different from that of paper, the printing machine can use magnets for splitting and double-sheet control. Due to the high hardness of the tinplate, the printing iron cannot use an advanced continuous iron conveying structure. Offset presses different from printing paper.