Specification of Gold Oil Coating On Tin Plate For Meat Cans:

Product name | Gold Oil Coating On Tin Plate For Meat Cans |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA(Batch annealing),CA(Continuous annealing) |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.18~0.23mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

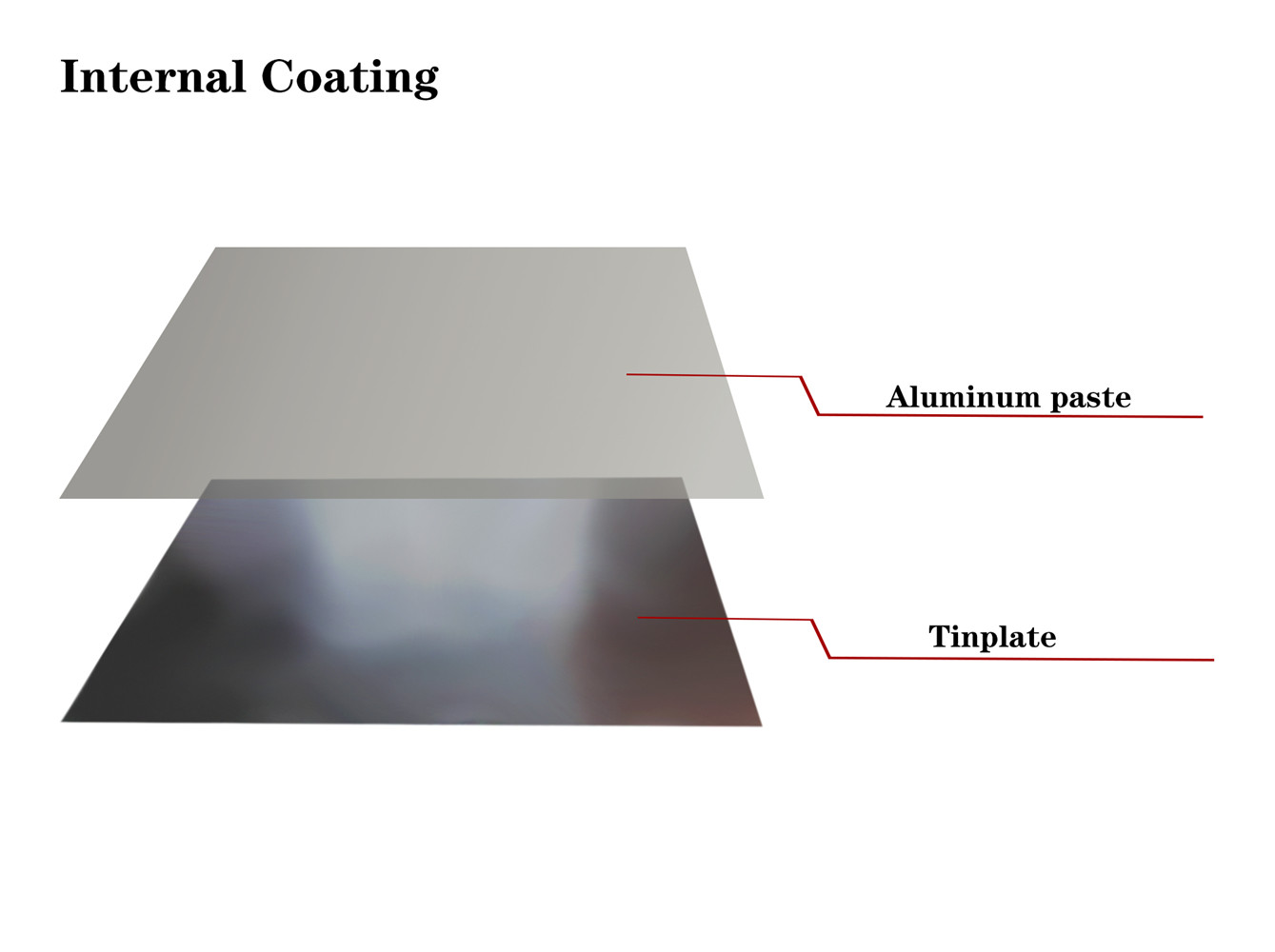

Internal coating | Gold lacquer/aluminized paste /transparency lacquer |

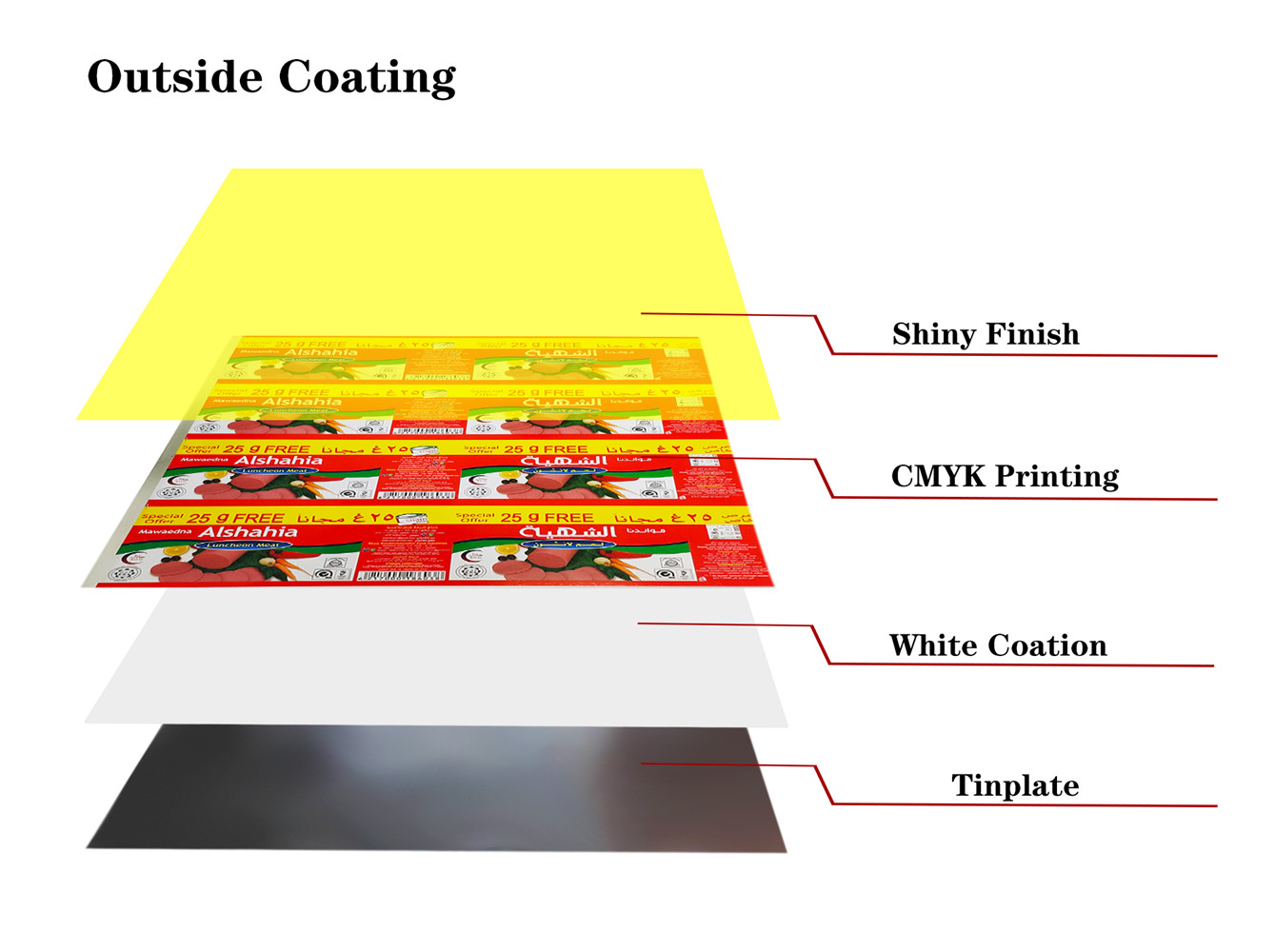

Outside coating | White coation+CMYK printing+Shiny finish/matte finish |

Application | For any collectible cans packing Box, Can, Bucket, etc(Food, meat,oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 5000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

Sizes available for tinplate:

Type | Normal Thickness | Normal Width | Normal Length | Weight | Coil Internal Diameter |

Sheet | 0.15~0.45mm | 508~960mm | 712~1145mm | 1~1.5ton | ------ |

Coil | 0.15~0.45mm | 508~960mm | 712~1145mm | 3~10ton | 410/508mm |

Standard for Tinplate Temper:

Code | Chineses | Japaness | American | Europen | International |

GB/T2520-2000 | JIS G3303-2002 | ASTM | DIN EN | ISO | |

T-2 | TH52+SE | T-2 | T-2(T53) | T52 | TH52+SE |

T-2.5 | TH55+SE | T-2.5 | TH55+SE | ||

T-3 | TH57+SE | T-3 | T-3(T57) | T57 | TH57+SE |

T-3.5 | |||||

T-4 | TH61+SE | T-4 | T-4(T61) | T61 | TH61+SE |

Tin coating weight on tinplate;

Tinplate Status | Coating Status | Former Coat | Coating W. Code | Normal C-W | Min. Ave. C-W | Remarks |

EPT | Equally Coating (E) | 10# | 1.1/1.1 | 1.1/1.1 | 0.9/0.9 | All specifications |

20# | 2.2/2.2 | 2.2/2.2 | 1.8/1.8 | |||

25# | 2.8/2.8 | 2.8/2.8 | 2.5/2.5 | |||

50# | 5.6/5.6 | 5.6/5.6 | 5.2/5.2 | |||

75# | 8.4/8.4 | 8.4/8.4 | 7.8/7.8 | |||

100# | 11.2/11.2 | 11.2/11.2 | 10.1/10.1 | |||

Classified Coat (D/A) | 25#/10# | 2.8/1.1 | 2.8/1.1 | 2.5/0.9 | ||

50#/10# | 5.6/1.1 | 5.6/1.1 | 5.2/0.9 | |||

50#/25# | 5.6/2.8 | 5.6/2.8 | 5.2/2.5 | |||

75#/25# | 8.4/2.8 | 8.4/2.8 | 7.8/2.5 | |||

75#/50# | 8.4/5.6 | 8.4/5.6 | 7.8/5.2 | |||

100#/25# | 11.2/2.8 | 11.2/2.8 | 10.1/2.5 | |||

100#/50# | 11.2/5.6 | 11.2/5.6 | 10.1/5.2 | |||

100#/75# | 11.2/8.4 | 11.2/8.4 | 10.1/7.8 |

What is tinplate coating?

Canned containers made of tinplate usually need to be coated with a coating on the inner surface, the purpose of which is to prevent the chemical interaction between the contents of the can and the can wall and the contamination of the contents by trace amounts of harmful substances, and to protect the freshness of the contents as well as the original flavor, the starting food can be stored, transported and sold for a long time without affecting its edible value.

Composition of printed tinplate coatings

The tinplate coating is mainly composed of three major film-forming substances, secondary film-forming substances and auxiliary film-forming substances.

① The main film-forming substance. It is a basic substance that makes printed tinplate paint adhere to the surface of an object and form a film layer, also known as a fixing agent or an adhesive. It can form a film with strong adhesion alone, or it can form a film with a secondary film-forming substance, which plays a decisive role in the properties of coatings and films.

② Second film-forming substance. It can't be formed separately from the main film-forming substance. The secondary film-forming substance in the printing tinplate coating is pigment, which is mainly divided into color pigment, rust-proof pigment and physical pigment.

(A) Colored pigments. In printing tinplate coatings, colored pigments are mainly used for covering and decoration, and are the most common type of pigments. The main coloring pigment used in printing tinplate coatings is titanium dioxide, which is titanium dioxide.

(B) Anti-rust pigment. Its main function is to prevent metal substrates from being corroded. It is divided into physical antirust pigments and chemical antirust pigments. The former can increase the density of the film layer and isolate the metal surface from water, air, etc. Once the film layer is broken, the rust prevention fails. The latter mainly depends on the chemical passivation of the metal surface by the pigment to prevent rust. Even if the film is damaged by a small amount, it still has a certain ability to prevent rust.

(C) extender pigment. Also known as filler, it is generally a white powder. It has almost no coloring and covering ability to the film layer, but has good chemical resistance, abrasion resistance, and low price. It can be mixed with colored pigments to increase the thickness of the film layer and improve its mechanical properties.

③ auxiliary film-forming substance. This substance cannot form a film layer, it can only help to form a film layer and improve the performance of the film layer. The auxiliary film-forming substances include solvents and auxiliary agents with certain functions. Solvents in printed tinplate coatings include organic solvents, water, auxiliaries and diluents, which are necessary for the preparation of liquid coatings; the role of the additives is to improve the performance of a particular aspect of printed iron coatings, usually in small amounts, but with significant effects. Commonly used auxiliaries are plasticizer, matting agent, antistatic agent, drier, curing agent, leveling agent, anti-sagging agent, etc.

Quality assurance:

1) The Right Material, First Time: Quality is the hallmark of our reputation.

2) Strict quality control,ensure any product satisfied with yours application .

3) Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department

Tinplate coating FAQ

Q: What is the MOQ for tinplate coating order?

A: Due to mass printing and production set up, minimum order quantity is roughly 2,000 ~3,000 pcs for each size.

Q: When can I get the price?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

Q: Do you make tools by yourselves?

A: Yes, we make all tools by ourselves. We have an in-house tooling department. So we can make custom molds at very low cost.

Q: Do you have any special varnishing effect in metal decoration?

A: In addition to traditional glossy and matted varnishes, we can offer crackle, wrinkle and pearl varnishes.

Q: What is your terms of delivery?

A: We accept EXW, FOB, CFR, CIF,etc. You can choose the one which is the most convenient or cost effective for you.

Q: What is your delivery time?

A: Usually within 15~20 days after getting deposit and confimed the sample.

mers.