Specification of Printing Metal Tin Sheet For coffee Tin Can (ground coffee tin):

Product name | Printing Metal Tin Sheet For coffee Tin Can |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.21~0.28mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

Internal coating | White coation or Gold lacquer |

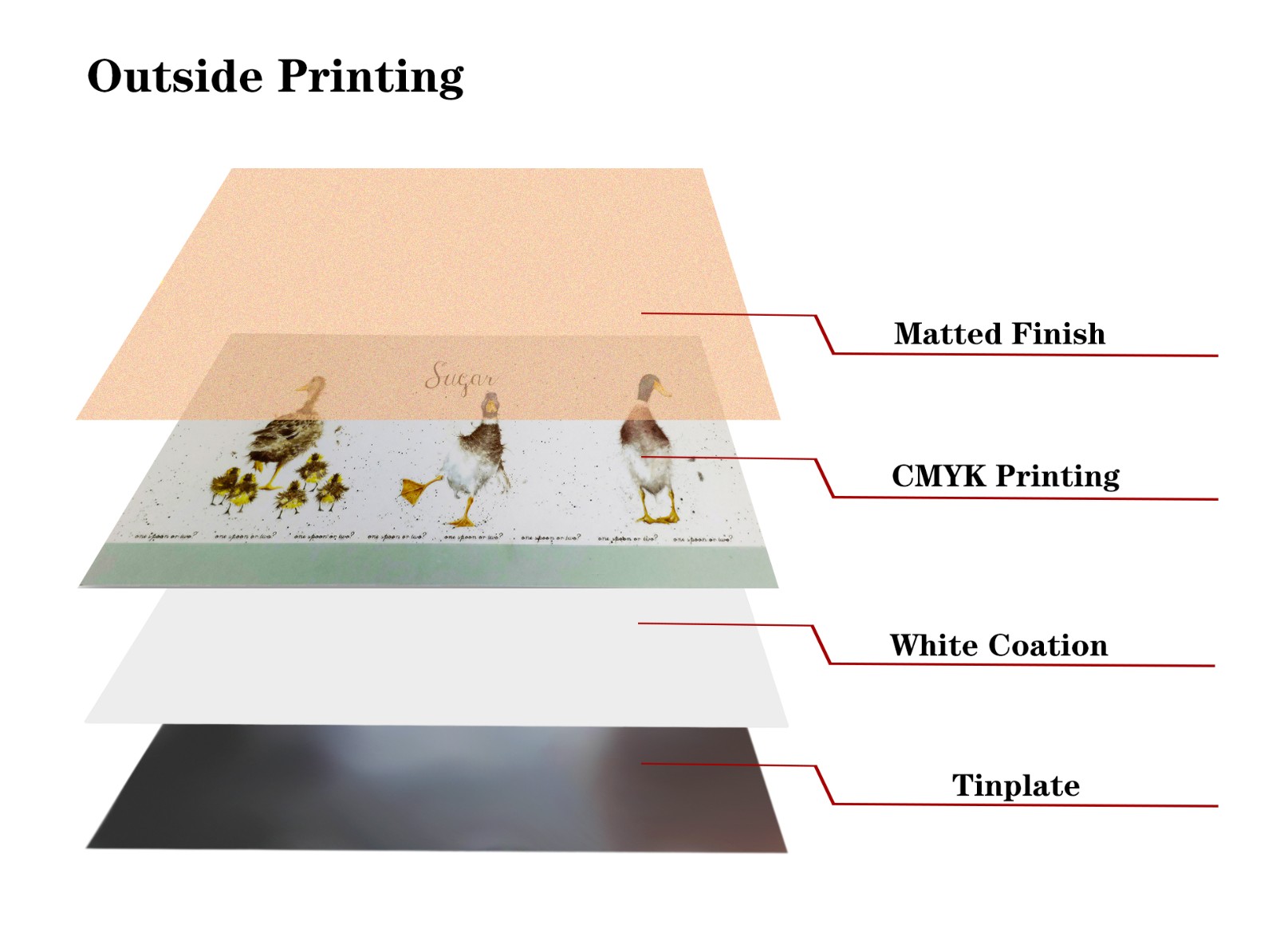

Outside printing | White coation+CMYK Printing+transparency lacquer |

Application | For any packing Tin can,Tin,Box, Can, Bucket, etc(coffee bean tin, oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

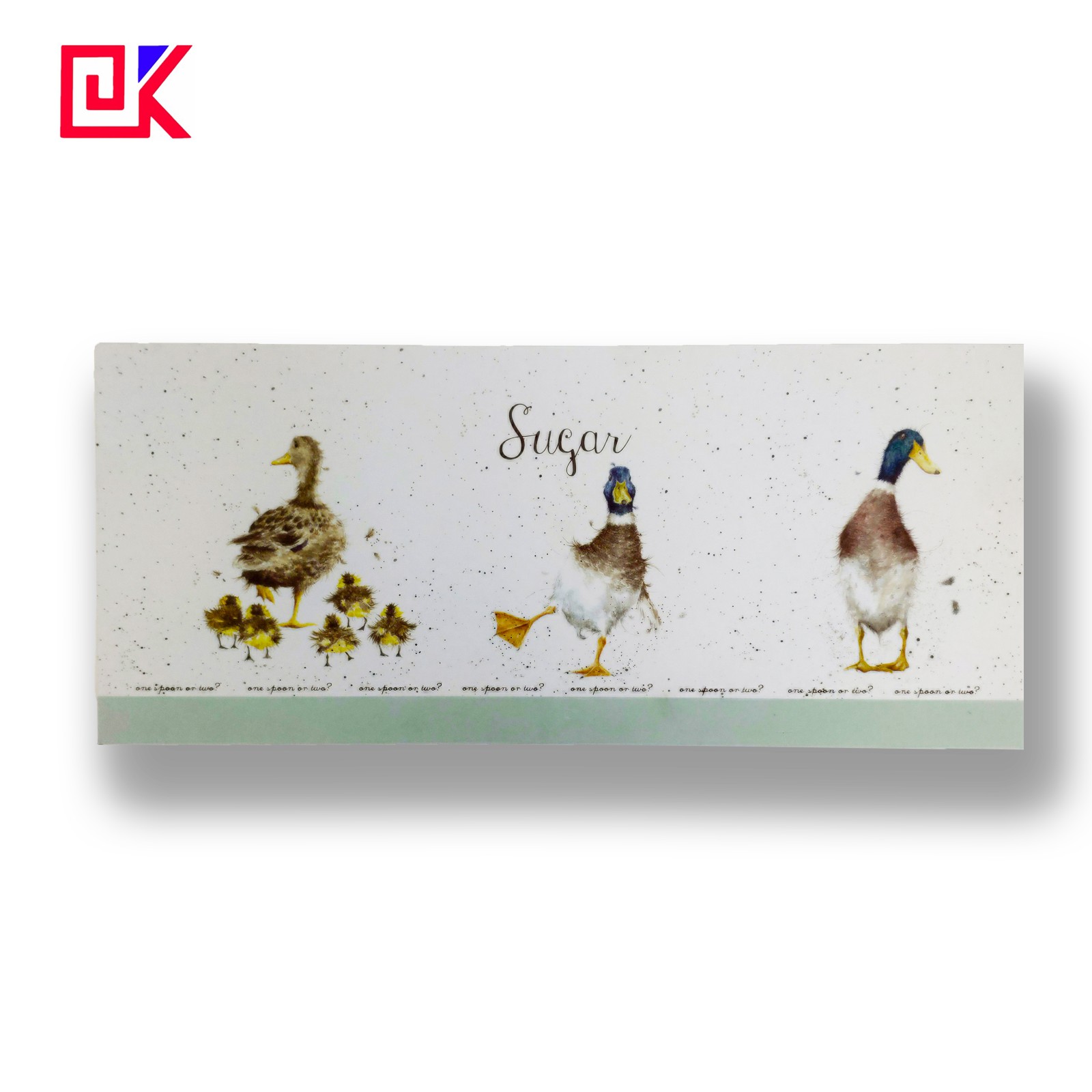

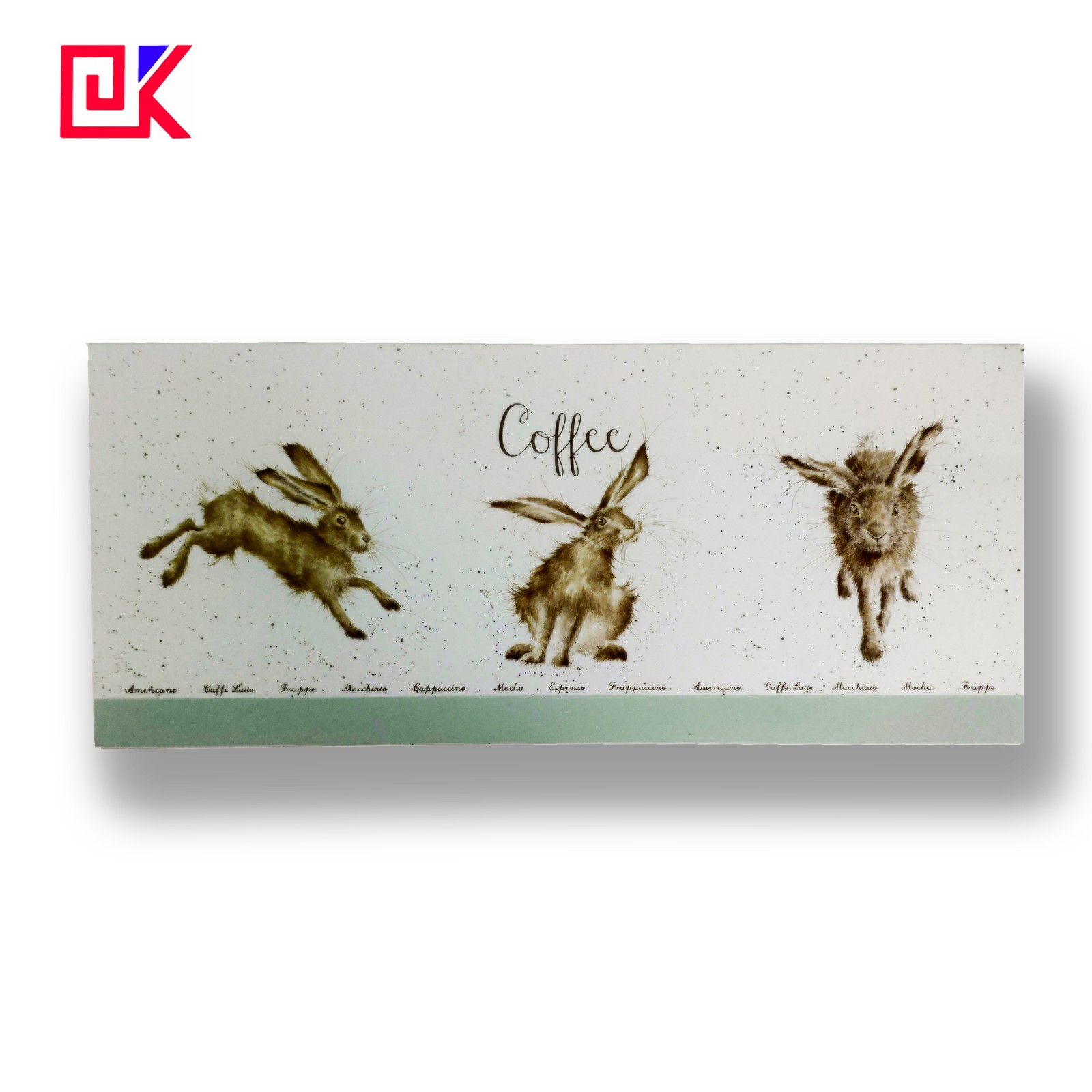

Product Show

Product Detail

Printing Detail

Product Show

Outside Printing

What is printing tin sheet?

Printing metal tin sheet is to print patterns on tinplate (tin-plated sheet). It mainly uses the physical properties of water and ink to repel, and uses printing pressure to transfer the printing text to tinplate through a blanket, which belongs to the principle of lithographic offset printing. This process has special requirements for inks.

FAQ

Q: What is the MOQ for tinplate printing order?

A: Due to mass printing and production set up, minimum order quantity is roughly 2,000 ~3,000 pcs for each size.

Q: When can I get the price?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

Q: Do you make tools by yourselves?

A: Yes, we make all tools by ourselves. We have an in-house tooling department. So we can make custom molds at very low cost.

Q: Do you have any special varnishing effect in metal decoration?

A: In addition to traditional glossy and matted varnishes, we can offer crackle, wrinkle and pearl varnishes.