Specification of Red White Coation Innner Tin Steel:

Product name | Red White Coation Innner Tin Steel |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA(Batch annealing),CA(Continuous annealing) |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.15~0.45mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

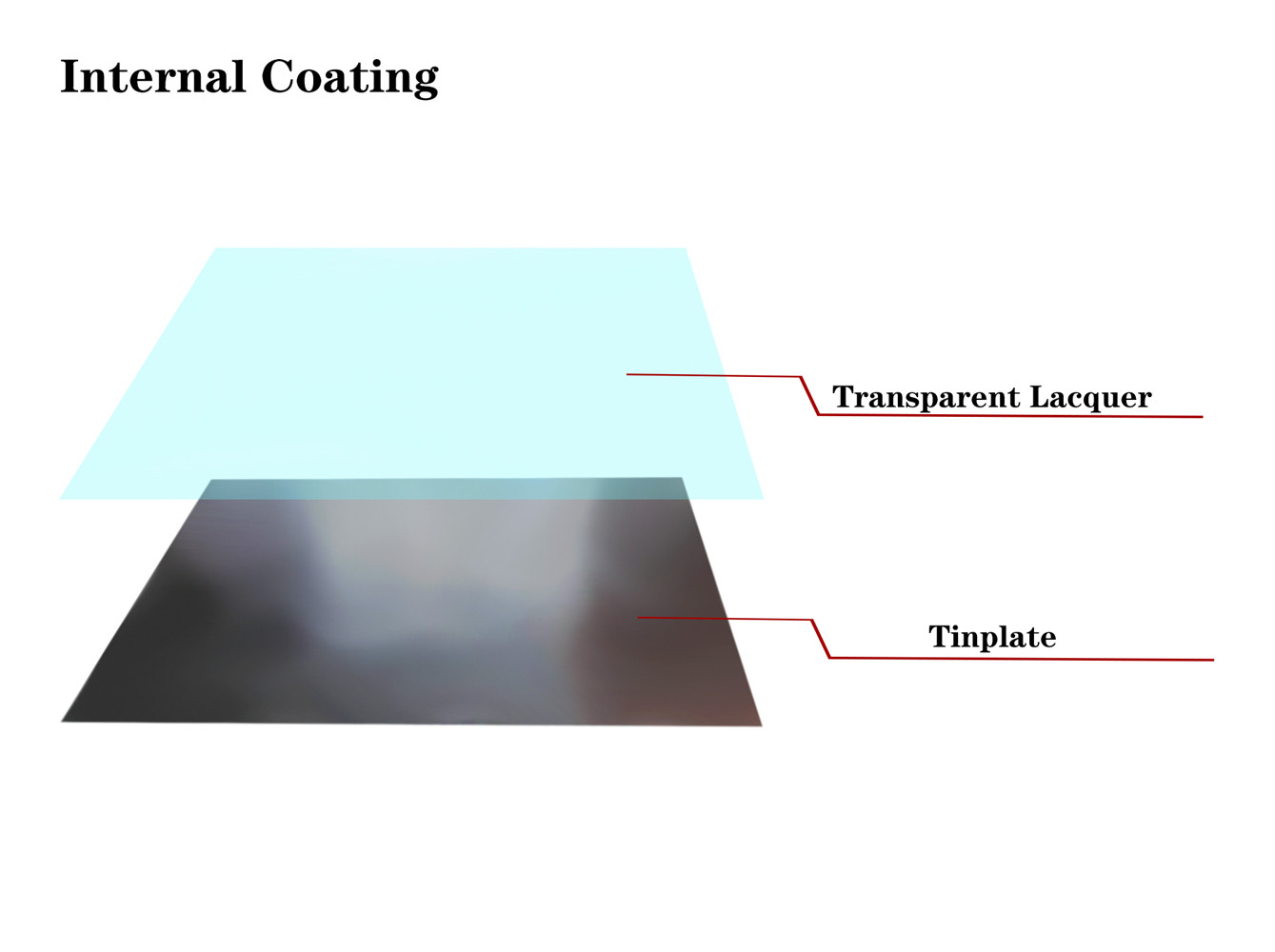

Internal coating | transparency lacquer |

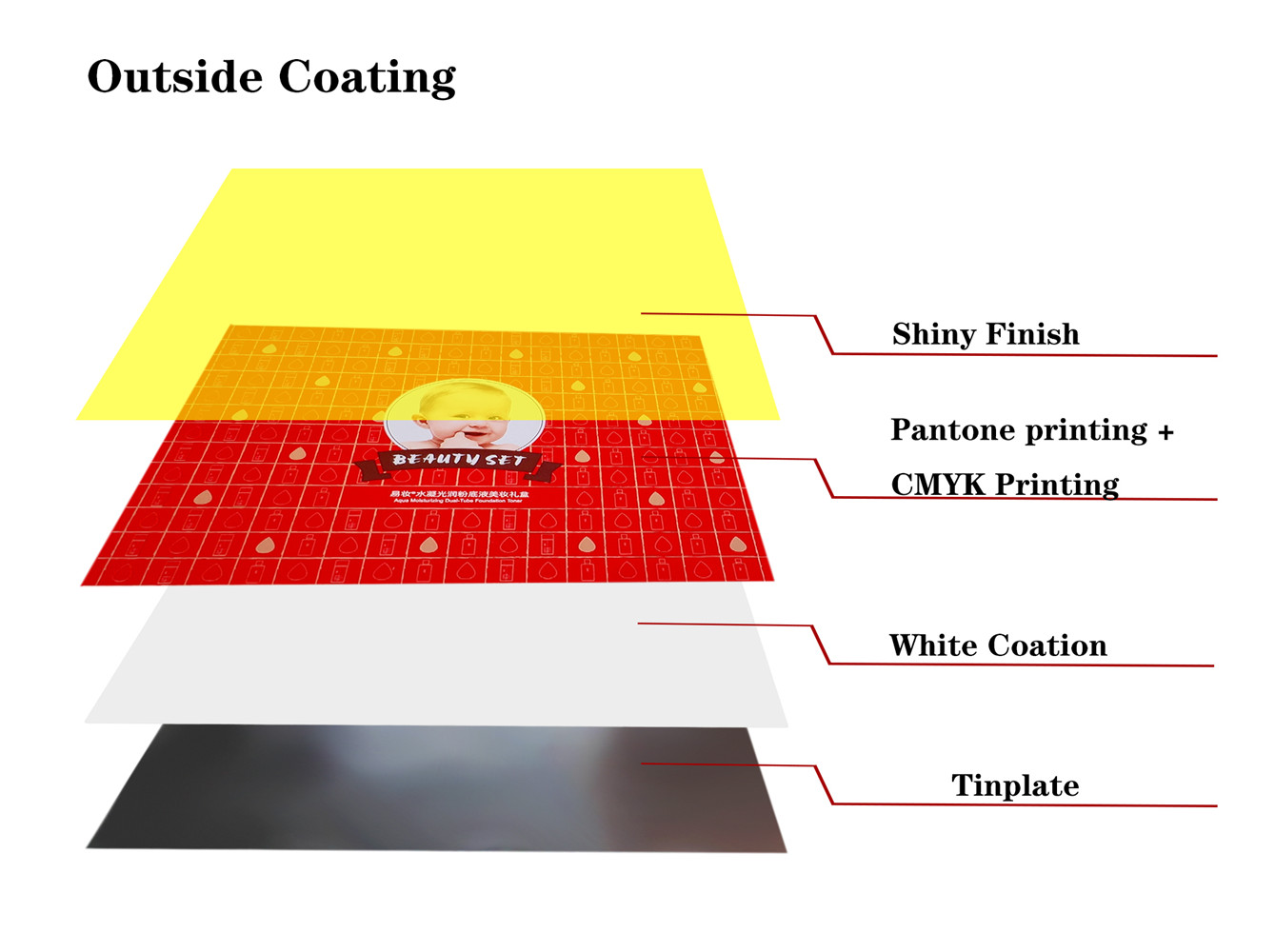

Outside coating | White coation+CMYK printing+Shiny finish |

Application | For any packing Box, Can, Bucket, etc(Food, oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 5000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

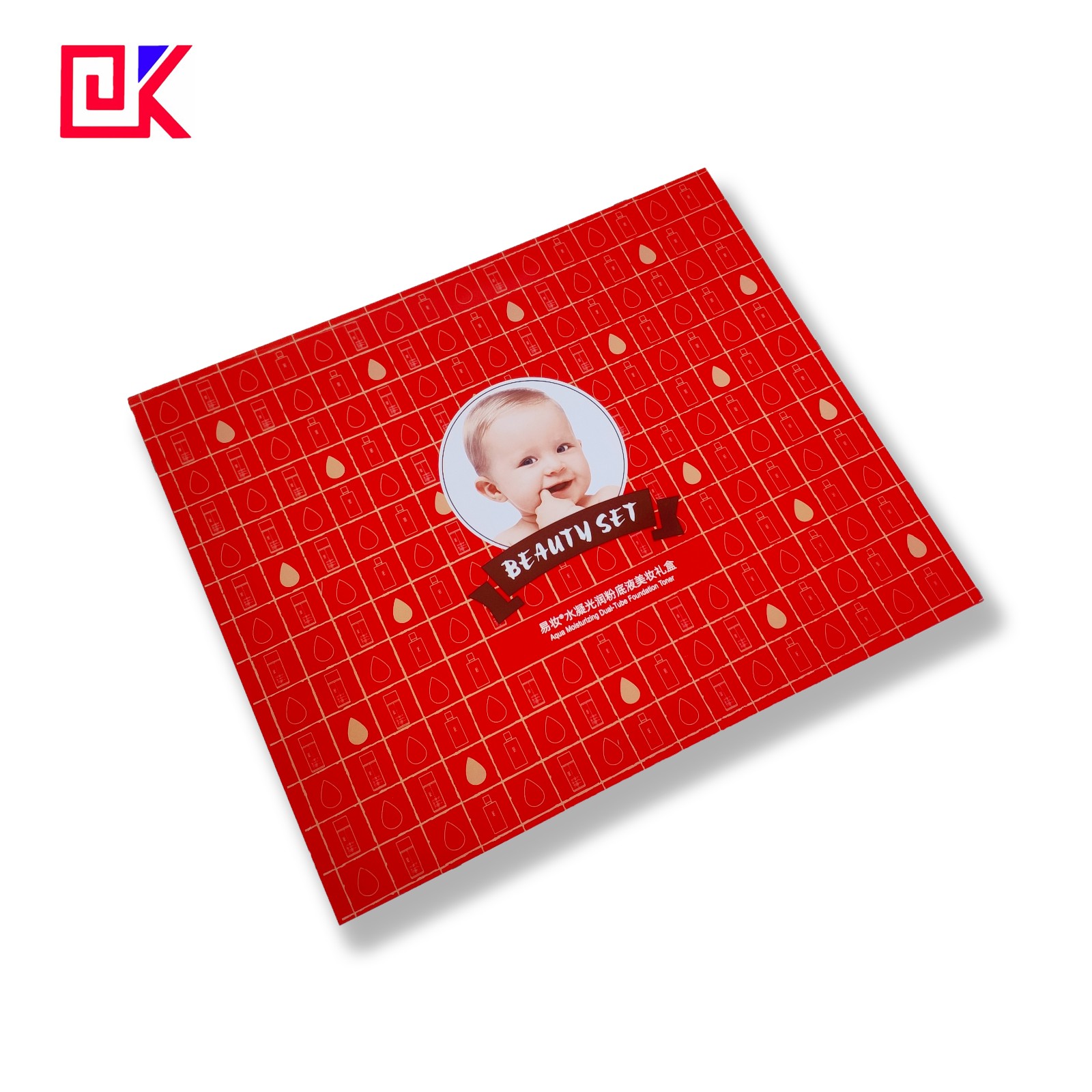

Product Show

Pantone printing

Tinplate For Metal Cosmetic Containers

Outside Coating

Internal Coating

All of our products support customization, if you need please feel free to contact us.

Standard of tin steel temper:

Standard Material | Q/BQB 455-2009 | JIS G3315-2008 | ASTM A623M-08 | EM 10202:1989 | EN 1020:2001 | ISO 11950:1995 |

Single Reduce | - | T-1 | T-1(49) | T50 | TS230 | TH50+CE |

T-1.5 | - | - | - | - | - | |

T-2 | T-2 | T-2(T53) | T52 | TS245 | TH52+CE | |

T-2.5 | T-2.5 | - | - | TS260 | TH55+CE | |

T-3 | T-3 | T-3(T57) | T57 | TS275 | TH57+CE | |

T-3.5 | - | - | - | TS290 | - | |

T-4 | T-4 | T-4(T61) | T61 | TH415 | TH61+CE | |

T-5 | T-5 | T-5(T65) | T65 | TH435 | TH65+CE | |

Double Reduce | DR-7M | - | DR-7.5 | - | TH520 | - |

DR-8 | LR-8 | DR-8 | DR550 | TH550 | TH550+CE | |

DR-8M | - | DR-8.5 | - | TH580 | TH580+CE | |

DR-9 | DR-9 | DR-9 | DR620 | TH620 | TH620+CE | |

DR-9M | DR-9M | DR-9.5 | DR-660 | - | TH660+CE | |

DR-10 | DR-10 | - | - | - | TH690+CE |

Tin coating on tin steel:

Classification | Designation of | Nominal tin (g/m2) | Min average (g/m2) | Remark |

Equai tin coating(E) | 1.1/1.1 | 1.1/1.1 | 1.8 | All specification |

2.2/2.2 | 2.2/2.2 | 4.0 | All specification | |

2.8/2.8 | 2.8/2.8 | 5.0 | All specification | |

5.6/5.6 | 5.6/5.6 | 10.5 | All specification | |

classification | 2.2/1.1 | 2.2/1.1 | 2.0/0.9 | All specification |

2.8/1.1 | 2.8/1.1 | 2.25/0.9 | All specification | |

5.6/1.1 | 5.6/1.1 | 5.05/0.9 | All specification | |

2.8/2.2 | 2.8/2.2 | 2.25/2.0 | All specification | |

5.6/2.2 | 5.6/2.2 | 5.05/2.0 | All specification | |

5.6/2.8 | 5.6/2.8 | 5.05/2.25 | All specification |

What is tin steel coating ?

Canned containers made of tin steel usually need to be coated with a coating on the inner surface, the purpose of which is to prevent the chemical interaction between the contents of the can and the can wall and the contamination of the contents by trace amounts of harmful substances, and to protect the freshness of the contents as well as the original flavor, the starting food can be stored, transported and sold for a long time without affecting its edible value.

Basic principles of tin steel inner coating:

The coating on the inside and outside of the canned container is a uniform coating with a thickness controllable on a tinplate lubricated surface with a roller coating machine before the tinplate is cut into a can body blank. The coating machine can perform coating operations when it is on its own through its own feeding equipment, and can also be matched with an iron printing machine to form a printing and coating operation line.

The rotating stainless steel feeding roller is half immersed in the feeding tray, and the paint brought by the belt is transferred to the rubber roller through the leveling roller. There is an imprinting cylinder under the rubber roller, which has a tooth decay device inside. When the tinplate runs before the rubber roller, the impression roller's teeth tightens one end of the iron plate, and the rubber roller and the impression roller cooperate to push the tinplate through and finish the painting operation. The thickness of the coating is controlled by the feed roller, the leveling roller, and the gap between the rubber cylinder and the impression cylinder. Because of the distance between the tinplate and the sheet, a small amount of paint was taken away by the impression cylinder. Use a scraper to scrape the impression cylinder clean (to prevent the back side from being coated with iron sheet). The scraped paint flows into the receiving tray, and then returns to the storage tank through the duct and is recycled.

The coating on the side seam welding part of the canned container should not be coated with paint, otherwise the can body blank will easily penetrate the side seam and cause waste cans during the high-frequency resistance welding process. Therefore, the operator needs to make grooves on the rubber roller according to the printing area of the can container. The coating is printed on the tinplate by a slotted rubber roller. The blank iron left in the slotted part is the high-frequency resistance welding part of the empty can.

We have realized in practice that the dimension of the slot should be 1 to 2 mm wider than the blanking dimension of practical welding, so that the blanking dimension printed can meet the requirements of empty can welding.

The painted tinplate is transported to the drying room via a conveyor belt, and is driven by the circulating chain to be cured at a high temperature. The drying room is generally divided into three parts: the first part is to preheat the iron sheet to the baking temperature; the second part is the constant temperature baking; the third part is to make the iron sheet cool sufficiently. The whole baking time needs 10 ~ 15min. After that, the iron sheet was unloaded by an automatic plate unloader, and the coating was transferred to the can-making process after passing the inspection and physical and chemical tests.

Application of tin steel coating:

① It is widely used in the canning industry to make cans, tins, boxes for packaging cosmetics, candy, biscuits, tea, milk powder, etc.

② It is a good capping material for glass, plastic and other bottles.

FAQ:

1). What is minimum order quantity?

A: The MOQ is about 2 tons for each size, but it is flexible, we would consider customer's requirement.

2). What kind of terms of payment?

A: Usually payment terms,L/C,T/T,etc.

3). Could offer us samples?

A: Yes, we can offer the samples within two working days, but if the samples are customized or special coatings, it may take more time.

4). Can you do Customization & Reproduction if I provide a sample?

A: Yes, we do Customization & Reproduction service.

5). Is the packaging safe and arriving in good conditions?

A: Yes, safe Packing guarantee , all the products will arrive at your door under good conditions.

We response to problem of shipping if there unfortunately is.

6). How long does it usually take to deliver the product?

A: We will make the shipment to you immediately. It will take about 20 to 40 days arrive worldwide. It depends on the order quantities and specifications.