Specification of Tinplate Tin Steel For Making Toys (tinplate toys):

Thickness | 0.18~0.35mm |

Width | 500~1000mm |

Material | MR SPCC |

Tin Coating | 1.1/1.1, 2.8/2.8/,5.6/5.6 |

Temper | T2~T4 |

Coil Weight | 3~10 MT |

Oiling | DOS |

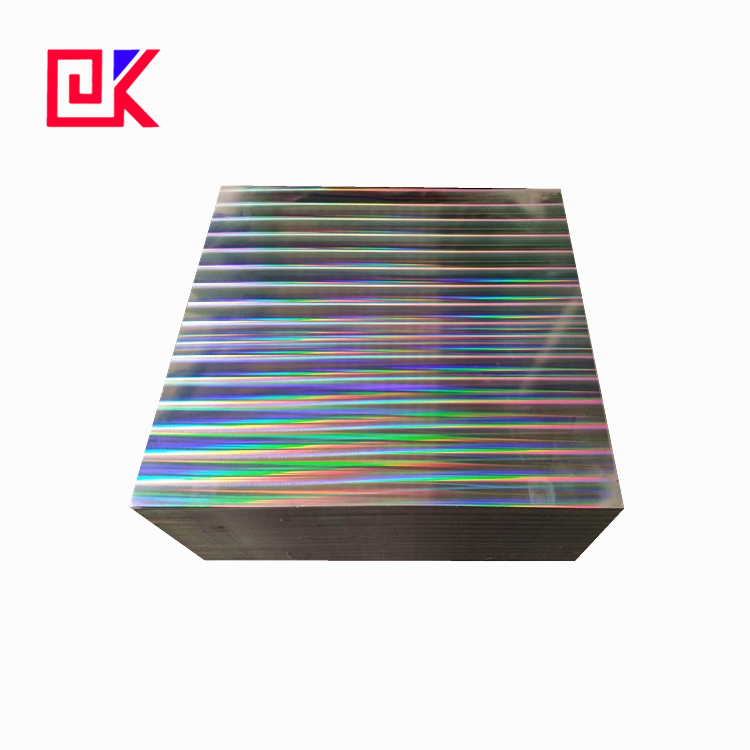

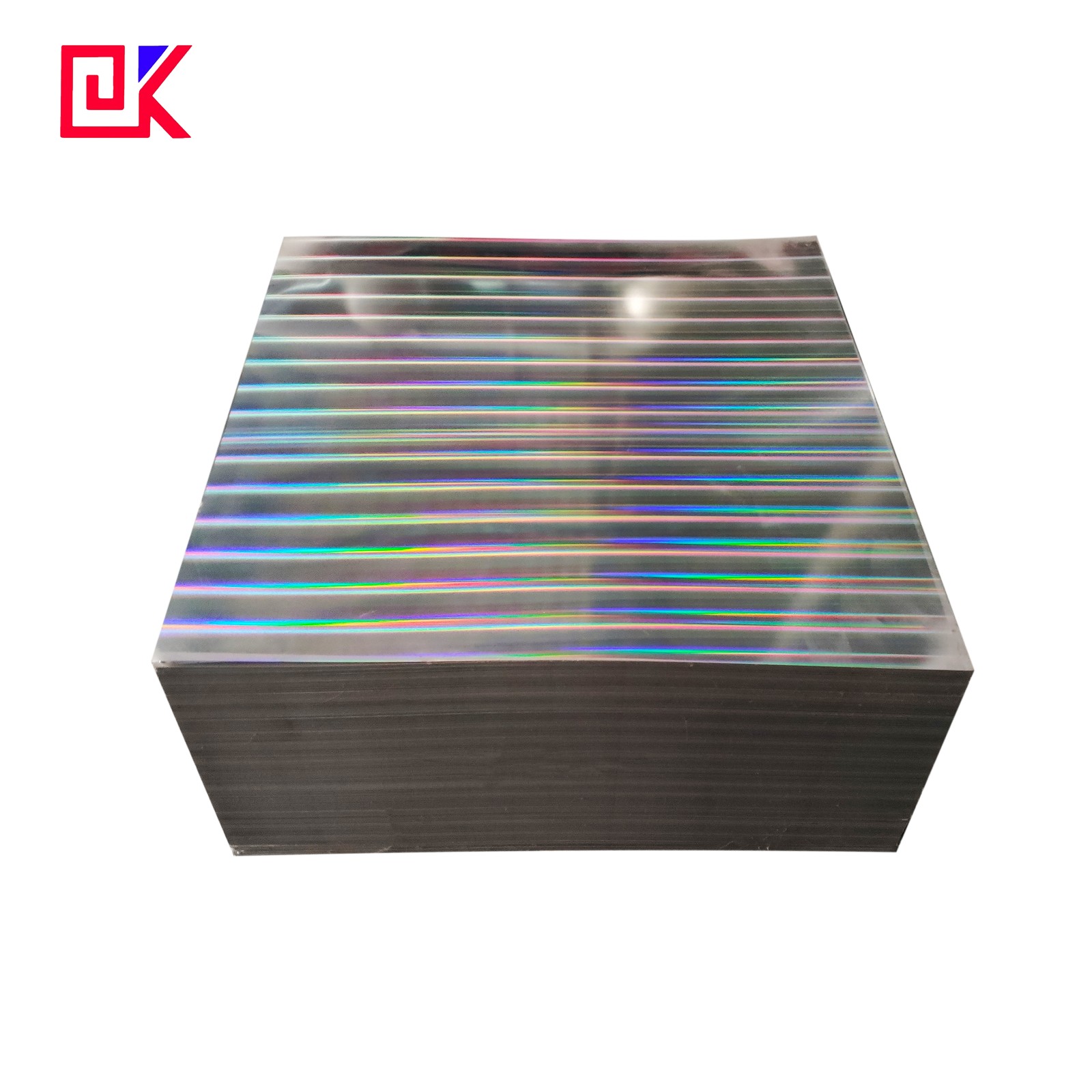

Surface Finish | Bright, Stone, Silver, Matt |

Annealing | CA, BA |

Packing | Wrapped completely with an inner cover of plasticor water proof papers with corners pertected |

Tinplate Tin Steel performance:

① Mechanical properties. The mechanical properties of Tinplate Tin Steel mainly refer to the mechanical properties of the steel substrate, including mechanical properties (tempering) and forming properties (cup burst value). The tempering degree is the hardness. The comprehensive mechanical properties of tin plate are generally described by tempering degrees. The tempering degree of tin plate is expressed by the surface Rockwell hardness value HR30T, and the symbol is formed by T plus a number. Different national standards have different expression methods for hardness. Table 2 lists the hardness expression methods and comparison of hardness ranges. Cupping value is mainly used to evaluate the plasticity and ductility of tin plate.

Table 2 : Comparison of hardness expression method and hardness range

Code | Chineses | Japaness | American | Europen | International |

GB/T2520-2000 | JIS G3303-2002 | ASTM | DIN EN | ISO | |

T-2 | TH52+SE | T-2 | T-2(T53) | T52 | TH52+SE |

T-2.5 | TH55+SE | T-2.5 | TH55+SE | ||

T-3 | TH57+SE | T-3 | T-3(T57) | T57 | TH57+SE |

T-3.5 | |||||

T-4 | TH61+SE | T-4 | T-4(T61) | T61 | TH61+SE |

② Corrosion resistance. Corrosion resistance is the most important property of Tinplate Tin Steel. The acid leaching time lag value, iron dissolution value, tin plating grain size, alloy-tin galvanic value, and tin layer thickness are collectively referred to as the five corrosion resistance indicators of the tinplate. The comprehensive evaluation of the five indicators should be used to comprehensively measure the plating Corrosion resistance of tin plate.

Application of Tinplate Tin Steel:

The use of Tinplate Tin Steel is very widely. From packaging materials for food and beverages to grease cans, chemical cans ,tinplate toys(tin plate car)and other miscellaneous cans, the strengths and characteristics of tinplate provide good physical and chemical maintenance of the contents.

For Grease cans:

Light will cause and accelerate the oxidation reaction of oils and fats, reduce nutritional value, and harmful substances may also occur. What ’s more serious is the damage of oily vitamins, especially vitamins D and A.

Packaging & Loading:

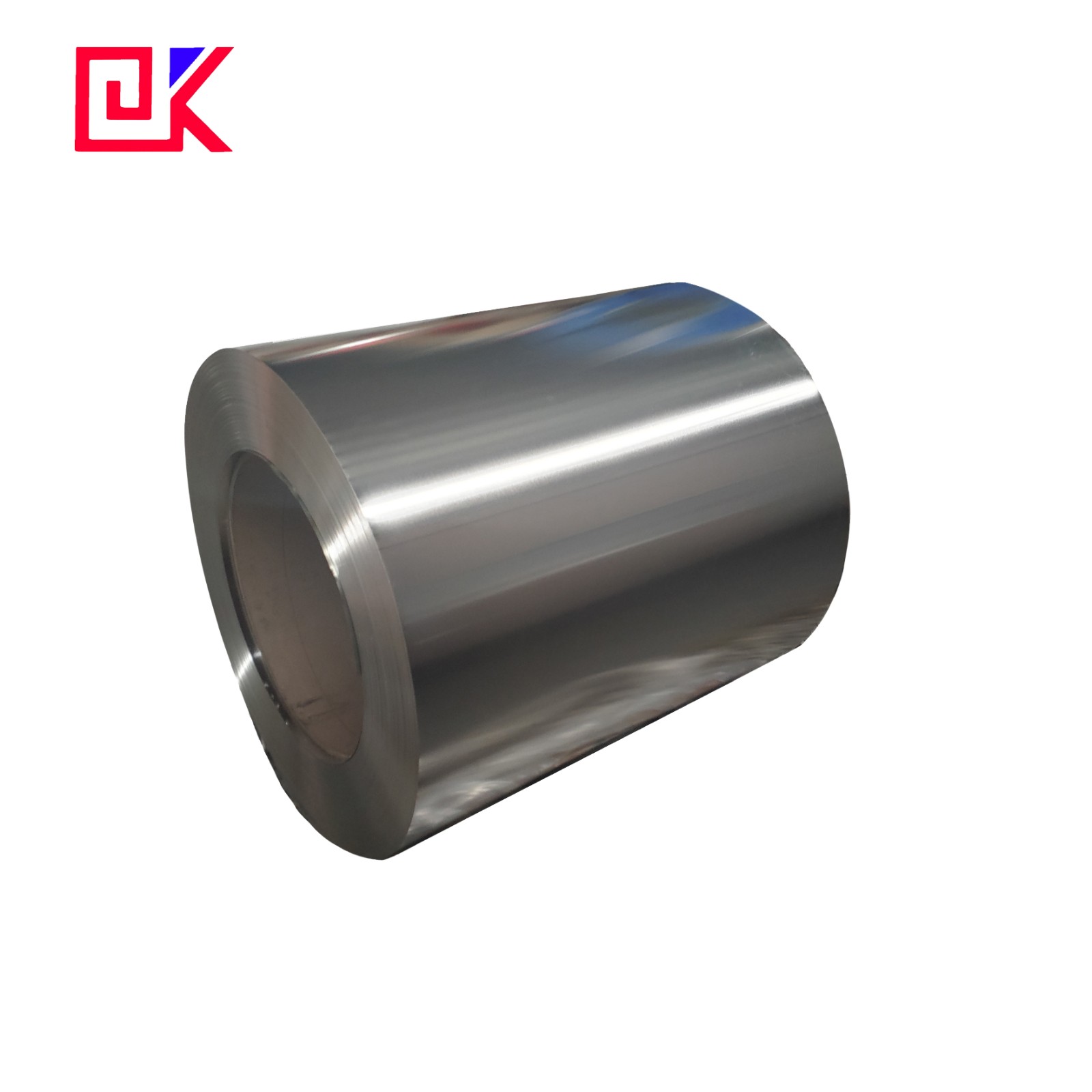

Packaging for tinplate coil:Anti-rust paper+Metal cover+Corner cap protected+Wood skids.

Packaging for tinplate sheet: Thin plastic film+Anti-rust paper+Metal cover+Metal corner cap protected+Binding strap+Pallet.

Loading by 20 feet container: about 20~25 tons