Specification of Tin Plate Coated Coil For Beef Cans (canned ham) MR Grade:

Thickness | 0.18~0.23mm |

Width | 700~1200mm |

Material | MR GRADE SPCC |

Tin Coating | 1.1/1.1, 2.8/2.8/,5.6/5.6 |

Temper | T1~T6/DR7~DR10 |

Coil Weight | 3~10 MT |

Oiling | DOS |

Surface Finish | Bright, Stone, Silver, Matt |

Annealing | CA, BA |

Packing | Wrapped completely with an inner cover of plastic or water proof papers with corners pertected |

Product Show

Product Detail

Printing Detail

Product Show

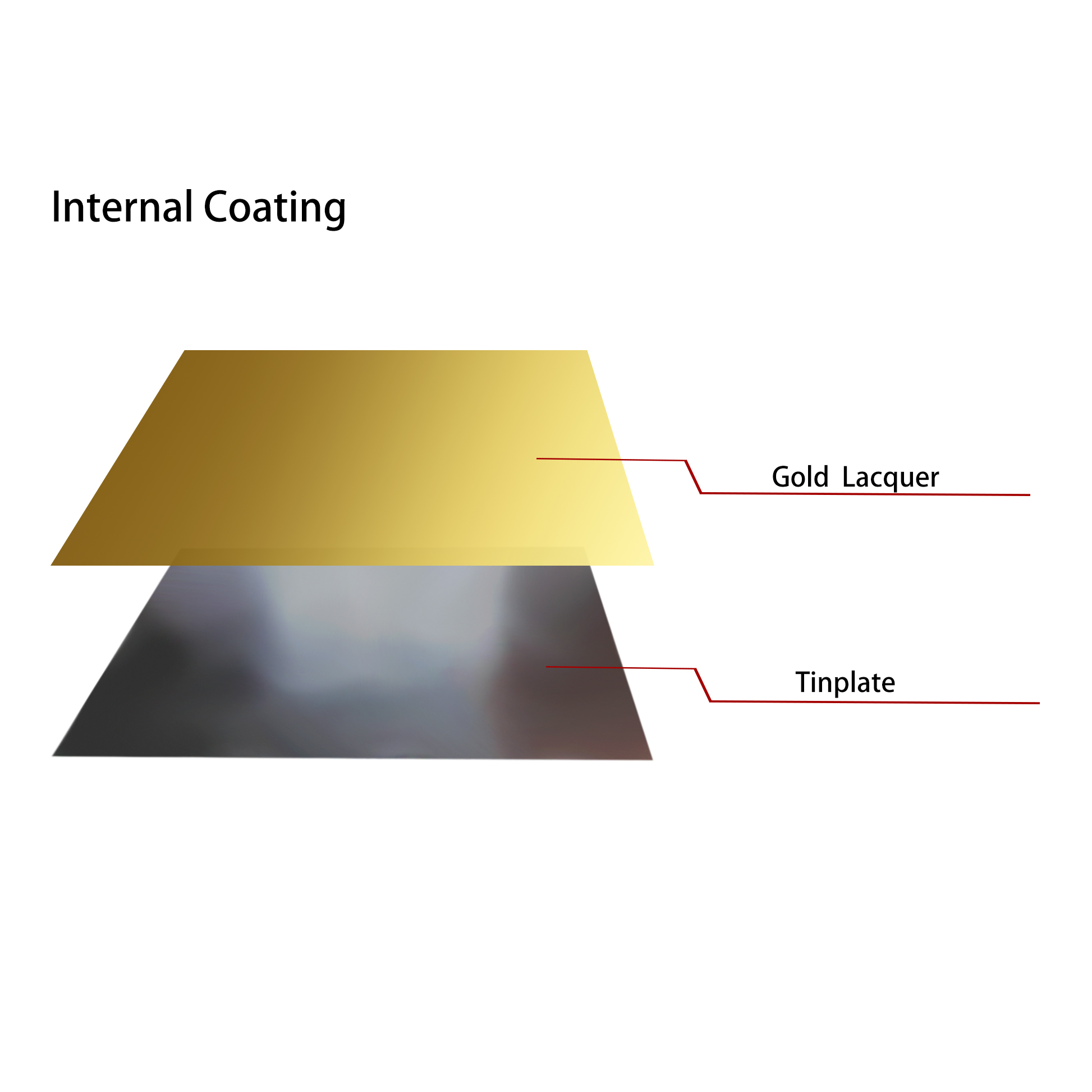

Internal Coating

All of our products support customization, if you need please feel free to contact us.

Tin plate coated coil steel substrate composition:

As Chinese tinplate companies mostly use Japanese tinplate, the Japanese standard JIS for steel substrate steel grades is now introduced. The standard does not specify the chemical composition of the steel type of the steel substrate, but provides three representative steel types: MR type, L type and D type, see Table.

Performance of three representative steel types of steel substrate:

steel types | Performance |

MR type | It has a low content of residual elements and good corrosion resistance, and is usually used for general purposes such as containers. |

L type | The content of copper, nickel, chromium, molybdenum and other residual elements is extremely small, which is suitable for food containers with better corrosion resistance. |

D type | Aluminum deoxidation full static steel is suitable for those who are prone to luder's line during deep drawing or processing. |

Surface state of Tin Plate Coated Coil:

Marks | Suface state | Characteristics | |

Single Reduce | B | Bright Surface | Glazed surface obtained a thin layer of chromium and chromium oxide which deposits on the smooth. |

Double Reduce | R | Stone Surface | Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone figures. |

S | Silver Surface | Glazed surface obtained after melting treatment of electronicned raw material strip with rough matt surface. | |

M | Matte Surface | Matte Surface | |

R | Stone Surface | Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone figures. | |

Introduction of Tin plate coated coil:

Tin plate coated coil, also known as tin-plated iron, is a common name for electroplated tin steel sheet, which refers to cold-rolled low-carbon steel sheet or steel strip coated with commercial pure tin on both sides. Tin is mainly used to prevent corrosion and rust. It combines the strength and formability of steel with the corrosion resistance, solderability, and aesthetic appearance of steel in one material. It has the characteristics of corrosion resistance, non-toxicity, high strength, and good ductility.

The tin box packaging produced with tin coil as a raw material has good sealing, preservation, light protection, sturdiness and unique metal decorative charm, which determines its wide coverage in the packaging container industry and is universally used internationally. Due to its strong oxidation resistance, diverse styles, and exquisite printing, tinplate packaging containers are popular with customers and are widely used in food packaging, pharmaceutical packaging, daily necessities packaging, instrumentation packaging, industrial packaging and other aspects.

Features of Tin Plate Coated Coil:

With unique and beautiful metallic gloss surface coating.

Excellent corrosion resistance.

Easy to weld and weld.

Various processing (bending, deep rolling, etc.) can be performed.

The surface is glossy and beautiful after printing.

Low surface resistance makes it easy to energize.

Meet the requirements of food hygiene law.

Tin plate coated coil advantages:

1) All materials are from internationally renowned first-class original factories;

2) Responsible professional high-quality personnel for operation;

3) Perfect and high-precision slitting / flat plate processing equipment;

4) Certificate of environmental protection and green material certification.

Tin coated coil application:

Tin plate coated coil is widely used in metal packaging for food,beverage, toys and son on:

1) From industry standard products to state-of-the-art products, they help everyday life around the world.

2) making food cans, beef cans, meat cans

3) Beverage cans with metal lid

4) 18 liter tin container

5) making biscuit cans

6) Spray can

7) Tinplate toys

8) Electrical and electronic parts

9) Bearing parts (sealing material)