Specification of Tinplate Sheets Printing For Beverage Container (soft drink cans):

Product name | Tinplate Sheets Printing For Beverage Container |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheets/Tin sheets (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.18~0.23mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

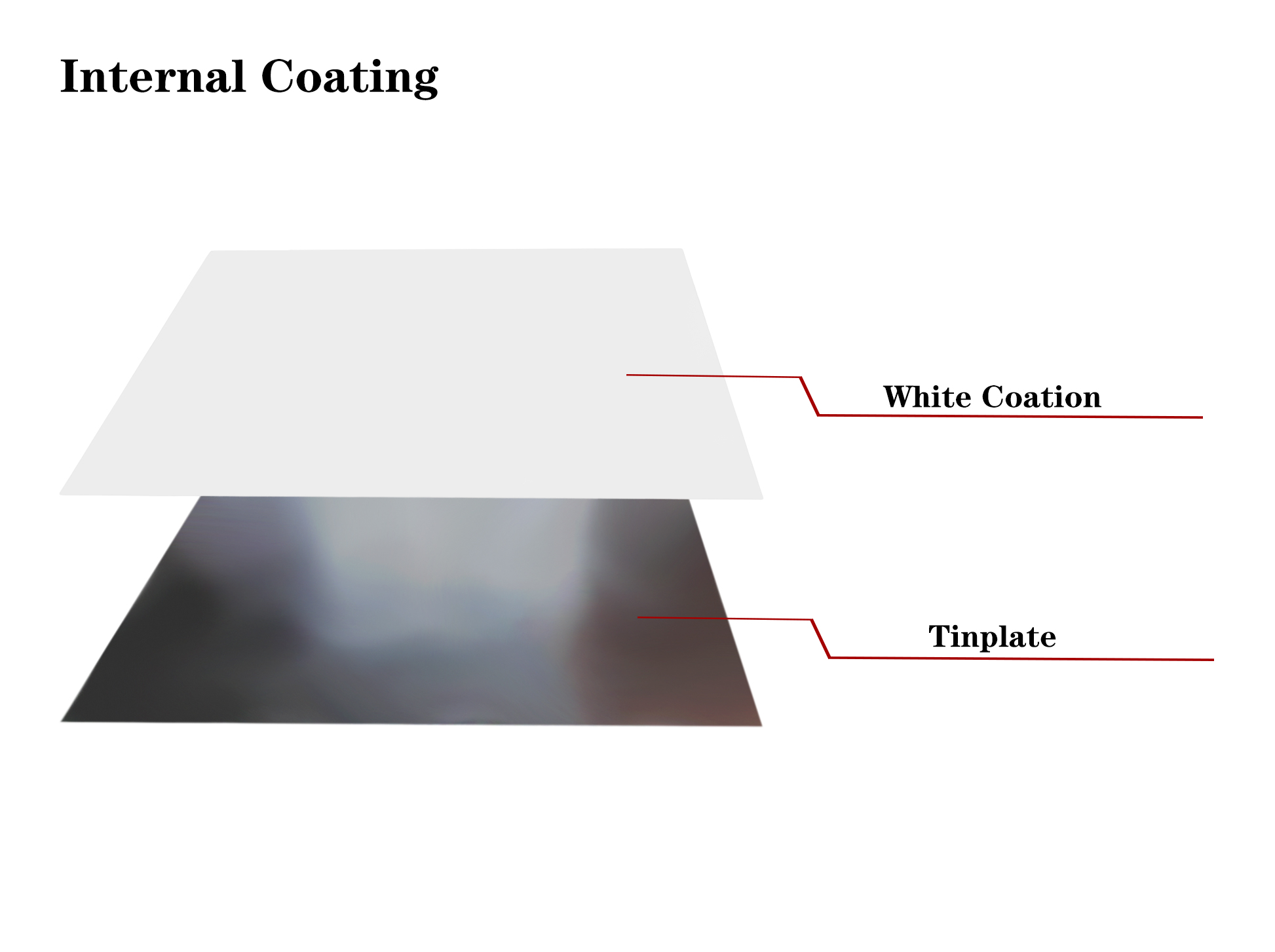

Internal coating | Gold lacquer+transparency lacquer |

Outside printing | White coation+CMYK Printing |

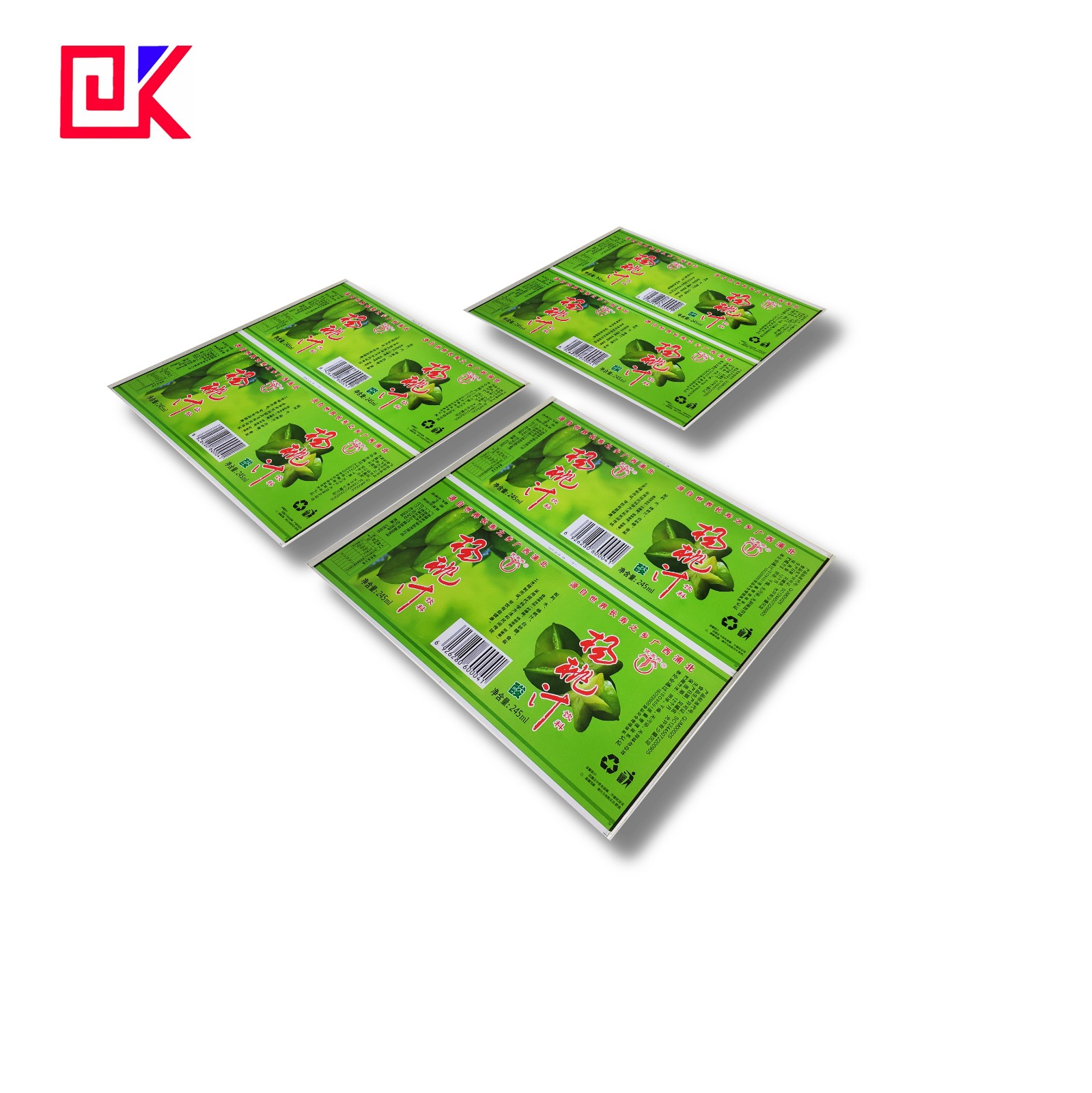

Printed Tinplate Sheet used for | For any packing container, Can, Bucket, etc(Beverage, milk, juice, soda cans, oil, food, cosmetics, perfume,toys, chemicals, etc.) |

Printing tinplate sheets MOQ | 2 tons per size |

Printing capacity | 4000 tons per Month |

Product Show

Printing detail

Printing Detail

Product Show

Internal Coating

Overview of printing on tin sheets:

Printing on tin sheets is to print patterns on tinplate (tin-plated sheet). It mainly uses the physical properties of water and ink to repel, and uses printing pressure to transfer the printing text to tin sheets through a blanket, which belongs to the principle of lithographic offset printing. This process has special requirements for inks.

Characteristics of printing on tin sheets:

The raw and auxiliary materials for tin sheets printing mainly include the following:tinplate sheets,tinplate coating,tinplate printing ink, PS plate, fountain solution, blanket, etc.tinplate sheets printing is different from other kinds of printing, the key important three kinds of raw material is:tinplate sheets,tinplate coating,tinplate printing ink.

About Tin sheet

1. Introduction of tin sheets

Tin sheets is referred to as tin plate sheets, commonly known as tinplate, which is a low-carbon thin steel plate with tin plating on both sides, with a thickness of about 0.15 to 0.45mm. Among them, metal tin is non-toxic, odorless, soft and so on. It adheres to the steel substrate, so that the steel substrate has good welding and processing performance.

2. How to choose a tin sheets

When selecting tin sheets, the requirements of the type of product (beverage container,aerosol can, milk powder can, battery iron, etc.) and the parts of the product (bottom cover, top cover, can body, etc.) should be considered at the same time ,please refer to Table for the selection method of tinplate.

Tin sheets selection table:

name | parts | Thickness(mm) | hardness | Tin coating | |

Beverage container Beverage can | Alu EOE cover | 0.24/0.25/0.26 | H19/H48/H39 | -- | |

Bottom cover | 0.20/0.21 | T3/T4 | #25/25 | ||

Can body | 0/19/0.20/0.21 | T4 | #10/10,25#/25 | ||

aerosol can | 3-piece high pressure aerosol can | Top cover | 0.35/0.40 | T4 | 25#/50 |

Bottom cover | 0.40 | T4 | 25#/50 | ||

Can body | 0.20/0.23 | T4 | 25#/25 | ||

3-piece normal aerosol can | Top cover | 0.31/0.32(D200/201/202 | T2/T3 | 25#/50 | |

0.32(D203.5/206/205) | T3/T4 | 25#/50 | |||

0.34/0.35(D207.5/211/209 | T3/T4 | 25#/50 | |||

Bottom cover | 0.28/0.30(D200/201/202 | T3/T4 | 25#/50 | ||

0.32(D203.5/206/205) | T4 | 25#/50 | |||

0.32(D207.5/211/209 | T4 | 25#/50 | |||

Can body | 0.19/0.20 | T3/T4 | #25/25 | ||

milk powder can | Top cover | 0.23 | T3/T4 | #25/25 | |

Bottom cover | 0.23 | T4 CA | #25/25 | ||

Can body | 0.23 | T4 CA | #25/25 | ||

battery | 0.18/0.19/0.20 | T2.5 | #10/25 | ||

Second: tin sheet printing ink

1. Introduction of printing ink

The properties of tin sheet printing ink are similar to ordinary inks, but there are special requirements in terms of heat resistance and adhesion. It mainly includes white ink and color ink.

2. How to choose tin sheet printing ink

When selecting printing inks,we first determine the product situation of our own enterprises, such as spray cans or food cans, ordinary cans or deep-drawn cans. This information is very important for us to choose tinlate printing inks.

In general, the selected printing ink should meet the following conditions:

1) The selected ink must have a test report of harmful chemical substances such as heavy metals produced by the SGS testing agency to ensure that the heavy metals and harmful chemical substances contained in the ink do not exceed the standard.

2) There is MSDS (Material Safety Data Sheet) report. Internationally known as the chemical safety information card, it is a comprehensive document about the hazardous chemicals's combustion, explosion, toxicity, environmental hazards, and safe use, emergency response measures for leakage, main physical and chemical parameters, laws and regulations.

3) It has the characteristics of heat resistance, solvent resistance, high temperature retort resistance, and processing resistance.

① Heat resistance. tin sheet printing ink is a heat curing ink. The printed tinplate needs to be heated and dried. The baking temperature is generally 150-205 ° C. Through heating, the ink binder changes from a small molecule to a macromolecular network structure, forming a hard ink film to ensure that the color of the ink does not change after baking.

② Solvent resistance. The last process of tinplate printing is varnishing. The varnish contains solvents such as benzene, ester, alcohol, and ketone. Therefore, the printing ink must have good solvent resistance, otherwise the pattern bleeding and discoloration will occur, affecting the quality of the printed product .

③ Resistance to boiling water and high temperature steam. For food cans, physical and chemical performance tests must be performed after printing according to the sterilization process requirements of the cans, including curing tests, acid resistance tests, sulfur resistance tests, etc. All three tests require the can body to be placed in different solutions. Heat to 100 ° C or 120 ° C and keep constant temperature for 30 minutes. After the test, the color and gloss of the tank should remain unchanged.

④ Processing resistance. After being dried at high temperature, the printing ink must have good mechanical processing properties, including adhesion, flexibility, and stamping resistance, to ensure that the ink will not fall off and wear during a series of mechanical processing molding processes.

⑤ High viscosity. As the tinplate surface does not have permeability, it is easy to increase the dots when printing. Compared with paper printing inks, tinplate printing should use high viscosity inks.

⑥ Transparency. The transparency of the ink is particularly important when the tint of the tinplate itself needs to be displayed in the package. For example, Red Bull beverage cans are printed with transparent golden ink.

Third: tin sheet coating

1. Introduction of tin sheet coating

tin sheet coating refers to the material that can be coated on the surface of tinplate. It is mainly used for the inner and outer coating of three-piece cans, two-piece cans, batteries, miscellaneous cans, and various bottle caps.

2. How to choose tin sheet coating

1) The choice of base coating

has good adhesion to tinplate and good affinity to the printing ink; has good thermosetting and flexibility; light color, low yellowing of the film layer after drying, so as to avoid Affects the whiteness of white paint or white ink; the solvent volatilizes at an appropriate speed and has good leveling properties; has good water resistance; non-toxic, odorless, and odorless, and does not affect the color and taste of the contents.

2) The choice of white coating

has good whiteness and saturation, does not yellow during printing and baking and post-processing sterilization; has good adhesion and flexibility; has good leveling, and the film is smooth and smooth, Has sufficient gloss; resistance to varnish solvent corrosion; good impact strength.

3) the choice of varnish

Has certain gloss and good leveling; light color, good color retention and heat resistance, no yellowing and discoloration after baking; sufficient surface hardness and frictional firmness; good flexibility and Impact resistance; good affinity for white coatings and printing inks; varnishes used in food cans also need to be resistant to steam sterilization.