Specification of White Coating Tinplate Sheet For Chemical Tins:

Product name | White Coating Tinplate Sheet For Chemical Tins |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA(Batch annealing),CA(Continuous annealing) |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.20~0.38mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

Internal coating | Gold lacquer /transparency lacquer |

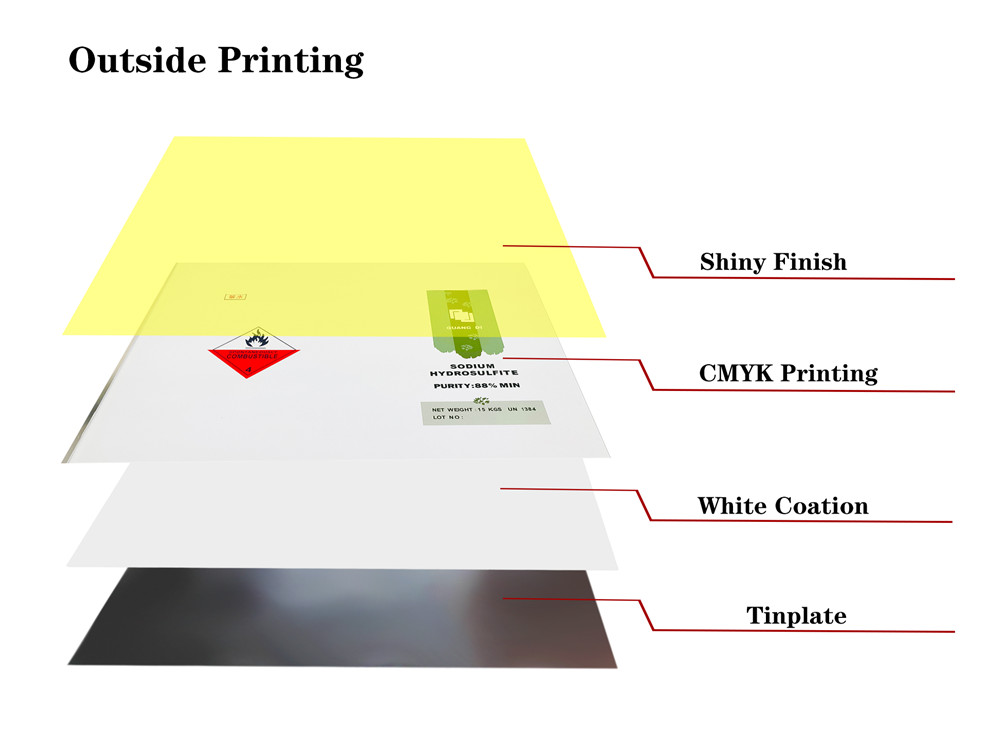

Outside coating | Shiny finish/matte finish |

Application | For any chemical cans packing, Tins,Boxes, Cans, Buckets, etc(Food, oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 5000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

Product Show

Tinplate Printing

Printing Show

Product Show

Outside Printing

Sizes available for tinplate:

Type | Normal Thickness | Normal Width | Normal Length | Weight | Coil Internal Diameter |

Sheet | 0.15~0.45mm | 508~960mm | 712~1145mm | 1~1.5ton | ------ |

Coil | 0.15~0.45mm | 508~960mm | 712~1145mm | 3~10ton | 410/508mm |

Standard for Tinplate Temper:

Code | Chineses | Japaness | American | Europen | International |

GB/T2520-2000 | JIS G3303-2002 | ASTM | DIN EN | ISO | |

T-2 | TH52+SE | T-2 | T-2(T53) | T52 | TH52+SE |

T-2.5 | TH55+SE | T-2.5 | TH55+SE | ||

T-3 | TH57+SE | T-3 | T-3(T57) | T57 | TH57+SE |

T-3.5 | |||||

T-4 | TH61+SE | T-4 | T-4(T61) | T61 | TH61+SE |

Surface Finish on coated and printed tinplate:

Marks | Suface state | Characteristics | |

Single Reduce | B | Bright Surface | Glazed surface obtained a thin layer of chromium and chromium oxide which deposits on the smooth. |

Double Reduce | R | Stone Surface | Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone figures. |

S | Silver Surface | Glazed surface obtained after melting treatment of electronicned raw material strip with rough matt surface. | |

M | Matte Surface | Matte Surface | |

R | Stone Surface | Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone figures. |

Certificate: Approved by the ISO 9001

Production capability:

1). Our company have two factories:one factory is tinplate coating and printing, and the other is tin can making , supply one-stop service from plain tinplate, coated tinplate ,printed tinplate ,lacquered tinplate till the final tin cans.

2). Smooth production ability 5,000tons each month .

3). OEM/ODM , Free of charges of Logo design and printing on your goods.

The main technical indicators of the tinplate coating:

The main technical indicators of the tinplate coating are: viscosity, surface tension, dryness, elasticity, impact strength, adhesion, gloss and so on.

① viscosity. Viscosity plays an important role in coating application. Too high viscosity is not conducive to roll coating. Too low viscosity results in insufficient film thickness.

② Surface tension. The surface tension of printed tinplate coatings depends on the physical properties of the coating itself. The surface tension of the coating is small and the leveling is good, which is also conducive to the implementation of the coating, and vice versa.

③ elasticity. Elasticity is also called flexibility. The requirements for the elasticity of printed tinplate coatings are high, otherwise it will affect the adhesion of the coatings after the metal can is formed.

④ Adhesion. It refers to the ability of the coating and the tinplate surface to adhere to each other. Adequate adhesion is the most basic requirement for printed tinplate coatings.

⑤ gloss. The gloss of the printed tinplate coating depends on the smoothness of the surface of the can body. A smooth surface has a high gloss and a rough surface has a low gloss.