Specification of Electrolytic Tinplate Sheet for jam jar lids :

Thickness | 0.15~0.45mm |

Width | 700~1200mm |

Material | MR SPCC |

Tin Coating | 1.1/1.1, 2.8/2.8/,5.6/5.6 |

Temper | T1~T6/DR7~DR10 |

Coil Weight | 3~10 MT |

Oiling | DOS |

Surface Finish | Bright, Stone, Silver, Matt |

Annealing | CA, BA |

Packing | Wrapped completely with an inner cover of plastic or water proof papers with corners pertected |

Composition of Electrolytic Tinplate Sheet for beverage bottle caps:

Electrolytic Tinplate Sheet is mainly composed of five parts: steel substrate, tin-iron alloy layer, tin layer, oxide film and oil film. The thickness, composition and performance of each part are shown in Table 1.

Table 1: Thickness, composition and properties of each part of Electrolytic Tinplate Sheet :

Name | thickness | composition | properties |

oil film | 2~5mg/cm² | Cottonseed oil or malonic acid diester | Lubrication and rust prevention |

oxide film | 1~3mg/cm² (Single-side coating) | Ferrous oxide, tin oxide, chromium oxide, metallic chromium | After chemical treatment, it has the functions of anti-rust, discoloration and anti-sulfide |

tin layer | 5.6~22.4mg/cm² | Pure tin | Beautiful, easy to weld, corrosion-resistant and non-toxic |

tin-iron alloy layer | <1g/cm² | Tin-iron alloy crystals | Corrosion resistance, but too thick for poor processability and solderability |

steel substrate | 0.2~0.3mm | Low-carbon steel | Good processing performance, with certain strength after can making |

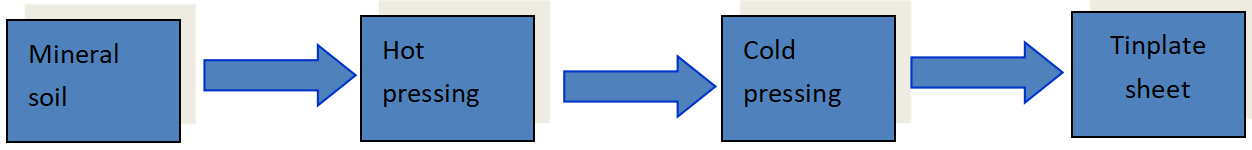

Electrolytic Tinplate Sheet raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of tinpate sheet can be extracted from 1.8 ton of iron ore

Application of Electrolytic Tinplate Sheet :

The use of Electrolytic Tinplate Sheet is very extensive. From packaging materials for food and beverages to grease cans, chemical cans and other miscellaneous cans, the strengths and characteristics of tinplate provide good physical and chemical maintenance of the contents.

Tinplate can be used to fill juice, coffee, tea and sports drinks, and can also be filled with cola, soft drinks, beer and other beverages. The high workability of tinplate cans has made their cans change a lot, no matter whether they are tall, short, large, small, or square or round, they can satisfy the diversified needs of beverage packaging and consumer preferences.

Quality assurance:

1) The Right Material, First Time: Quality is the hallmark of our reputation.

2) Strict quality control,ensure any product satisfied with yours application .

3) Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department