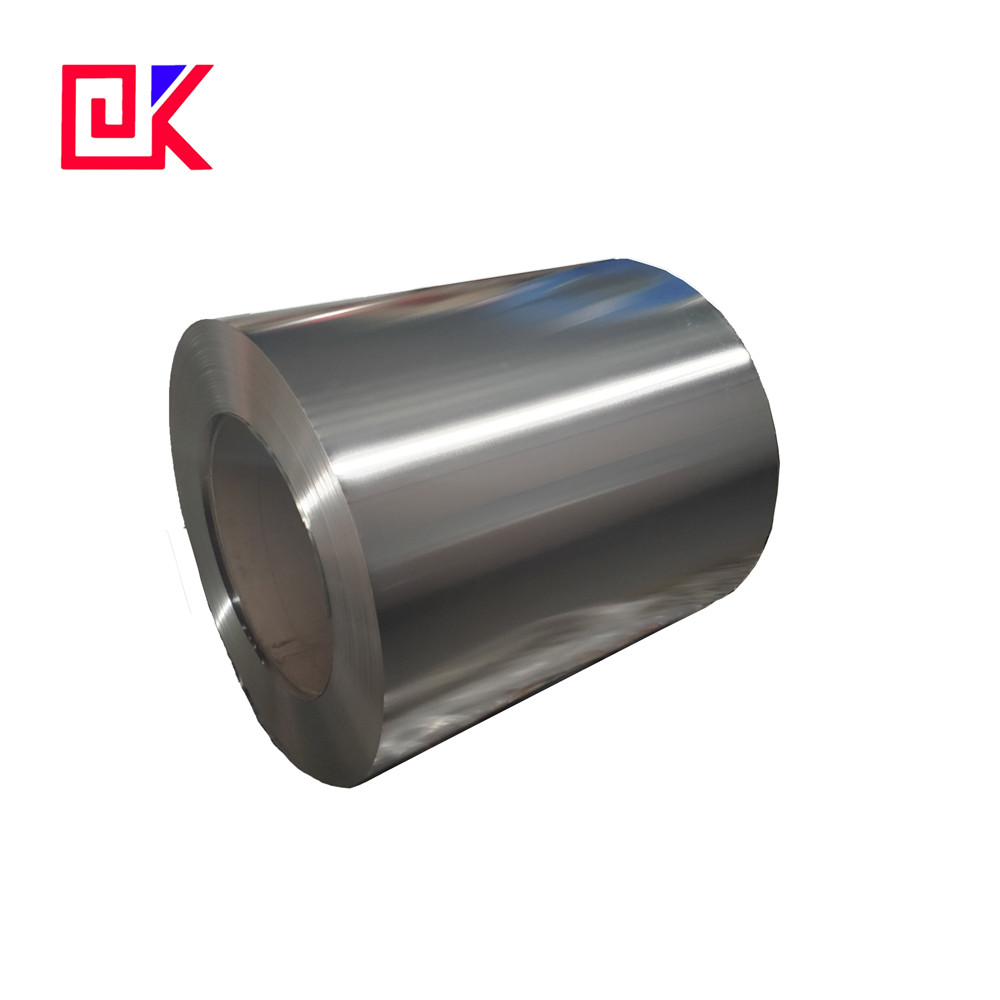

Specification of Food Grade Tinplate Sheet For Food Cans:

Thickness | 0.15~0.2mm |

Width | 700~1200mm |

Material | MR SPCC |

Tin Coating | 1.1/1.1, 2.8/2.8/,5.6/5.6 |

Temper | T1~T6/DR7~DR10 |

Coil Weight | 3~10 MT |

Oiling | DOS |

Surface Finish | Bright, Stone, Silver, Matt |

Annealing | CA, BA |

Packing | Wrapped completely with an inner cover of plastic or water proof papers with corners pertected |

Tinplate sheet classification:

According to different tin plating processes, tinplate can be divided into two types: hot-dip tinplate and electroplated tinplate. Hot-dip tinplate is made of tin coating with liquid coating process. Its coating is thick, and the thickness is difficult to control. The amount of tin consumed is large, so its application is limited. Electroplated tinplate, also known as cold-rolled tinplate, is plated on steel substrate .The tin film is evenly plated on it, and the plating methods mainly include alkaline plating method, halogen plating method and boron fluoride plating method.

The size of tinplate sheet:

The commonly used thicknesses are: 0.15mm,0.18mm,0.20mm, 0.23mm, 0.25mm, 0.28mm,0.30mm,0.35mm,0.38mm,0.45mm; the commonly used widths are: 775mm, 800mm, 875mm, 900mm, 950mm; the length can be selected within the allowable range to meet each The most economical requirements for container-type materials. In addition, in order to reduce scrap, manufacturers will provide a variety of bottom and cover corrugated iron.

How to choose tinplate:

When selecting tinplate, the requirements of the type of product (beverage can,aerosol can, milk powder can, Fruit and Vegetable Cans, Fish and Meat Cans, battery iron, etc.) and the parts of the product (bottom cover, top cover, can body, etc.) should be considered at the same time ,please refer to Table for the selection method of tinplate.

Tinplate selection table:

name | parts | Thickness(mm) | hardness | Tin coating | |

Beverage can | Alu EOE cover | 0.24/0.25/0.26 | H19/H48/H39 | -- | |

Bottom cover | 0.20/0.21 | T3/T4 | #25/25 | ||

Can body | 0/19/0.20/0.21 | T4 | #10/10,25#/25 | ||

aerosol can | 3-piece high pressure aerosol can | Top cover | 0.35/0.40 | T4 | 25#/50 |

Bottom cover | 0.40 | T4 | 25#/50 | ||

Can body | 0.20/0.23 | T4 | 25#/25 | ||

3-piece normal aerosol can | Top cover | 0.31/0.32(D200/201/202 | T2/T3 | 25#/50 | |

0.32(D203.5/206/205) | T3/T4 | 25#/50 | |||

0.34/0.35(D207.5/211/209 | T3/T4 | 25#/50 | |||

Bottom cover | 0.28/0.30(D200/201/202 | T3/T4 | 25#/50 | ||

0.32(D203.5/206/205) | T4 | 25#/50 | |||

0.32(D207.5/211/209 | T4 | 25#/50 | |||

Can body | 0.19/0.20 | T3/T4 | #25/25 | ||

milk powder can | Top cover | 0.23 | T3/T4 | #25/25 | |

Bottom cover | 0.23 | T4 CA | #25/25 | ||

Can body | 0.23 | T4 CA | #25/25 | ||

battery | 0.18/0.19/0.20 | T2.5 | #10/25 | ||

Our advantage:

Whether you need structural steel, complex miscellaneous metals, or stock steel material you will get:

1. The Right Material, First Time: Quality is the hallmark of our reputation.

2. On Time Delivery: Your projects stay on schedule.

3. Ongoing Communication: Everyone is fanatically responsive to your needs. We handle the project so there are no surprises for you.

4. ISO Certification: We help you meet your goals plus the goals of your owners/customers.

Features of tinplate products:

1.Excellent corrosion resistance can meet the corrosion resistance of different content requirements

2. Excellent finishing of various coatings and inks

3. Excellent welding can be used for welding manufacturing every kind of canned

4. Excellent processing and strength

5. Beautiful appearance

FAQ:

1). What is minimum order quantity?

A: The MOQ is about 2 tons for each size, but it is flexible, we would consider customer's requirement.

2). What kind of terms of payment?

A: Usually payment terms,L/C,T/T,etc.

3). Could offer us samples?

A: Yes, we can offer the samples within two working days, but if the samples are customized or special coatings, it may take more time.

4). Can you do Customization & Reproduction if I provide a sample?

A: Yes, we do Customization & Reproduction service.