Specification of Blue Coation Tin Electrolytic Tinplate Coil:

Product name | Blue Coation Tin Electrolytic Tinplate Coil |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA(Batch annealing),CA(Continuous annealing) |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.15~0.45mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

Internal coating | Gold lacquer /transparency lacquer |

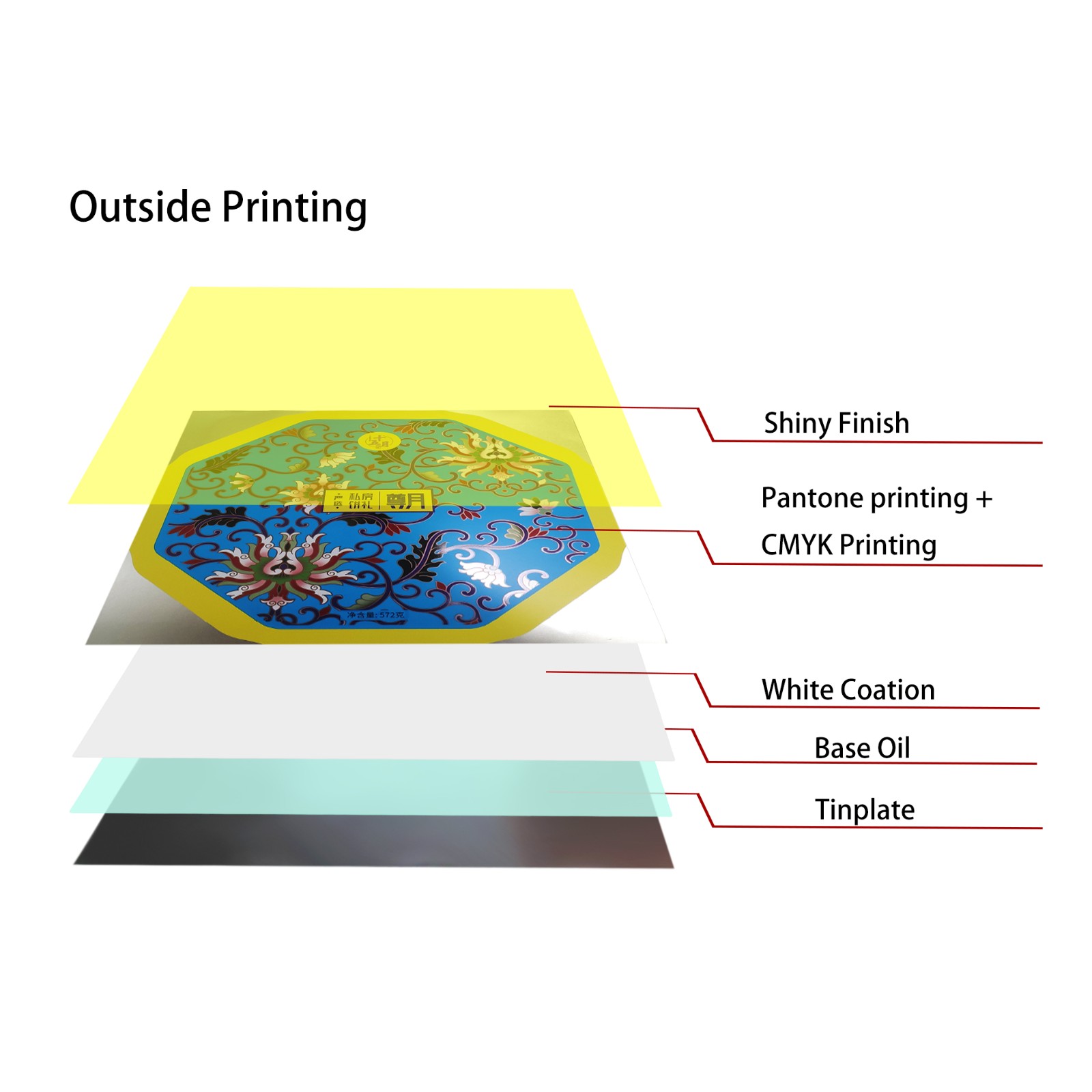

Outside coating | Shiny finish/matte finish |

Application | For any packing Box, Can, Bucket, etc(Food, oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 5000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

Product Design

Printing Detail

steel packaging

metal printing

Outside Printing

All of our products support customization, if you need please feel free to contact us.

Standard for electrolytic tinplate coil temper:

Standard Material | Q/BQB 455-2009 | JIS G3315-2008 | ASTM A623M-08 | EM 10202:1989 | EN 1020:2001 | ISO 11950:1995 |

Single Reduce | - | T-1 | T-1(49) | T50 | TS230 | TH50+CE |

T-1.5 | - | - | - | - | - | |

T-2 | T-2 | T-2(T53) | T52 | TS245 | TH52+CE | |

T-2.5 | T-2.5 | - | - | TS260 | TH55+CE | |

T-3 | T-3 | T-3(T57) | T57 | TS275 | TH57+CE | |

T-3.5 | - | - | - | TS290 | - | |

T-4 | T-4 | T-4(T61) | T61 | TH415 | TH61+CE | |

T-5 | T-5 | T-5(T65) | T65 | TH435 | TH65+CE | |

Double Reduce | DR-7M | - | DR-7.5 | - | TH520 | - |

DR-8 | LR-8 | DR-8 | DR550 | TH550 | TH550+CE | |

DR-8M | - | DR-8.5 | - | TH580 | TH580+CE | |

DR-9 | DR-9 | DR-9 | DR620 | TH620 | TH620+CE | |

DR-9M | DR-9M | DR-9.5 | DR-660 | - | TH660+CE | |

DR-10 | DR-10 | - | - | - | TH690+CE |

Surface state of electrolytic tinplate coil:

Marks | Suface state | Characteristics |

B | Bright rough | Glazed surface obtained after melting treatment of electroninned smooth raw material strip featuring certain oriented rubstone figure. |

R | Stone rough | Glazed surface obtained after melting treatment of electroninned raw material strip featuring certain oriented rubstone figure. |

S | Silver rough | Glazed surface obtained after melting treatment of electroninned raw material strip with rough matt surface. |

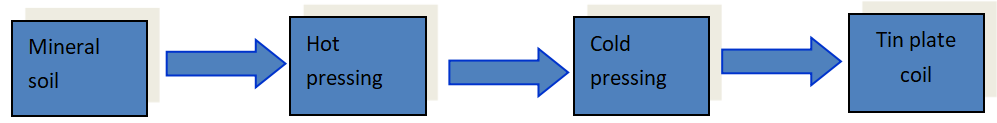

Tin Electrolytic Tinplate Coil raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of Tin Electrolytic Tinplate Coil can be extracted from 1.8 ton of iron ore

Certificate: Approved by the ISO 9001

Production capability:

1). Our company have two factories:one factory is tinplate coating and varnishing, and the other is tin can making , supply one-stop service from plain tinplate, coated tinplate ,printed tinplate ,lacquered tinplate till the final tin cans.

2). Smooth production ability 5,000tons each month .

3). OEM/ODM , Free of charges of Logo design and printing on your goods .

what is electrolytic tinplate coil coating?

Electrolytic tinplate coil coating refers to tinplate with a thick organic compound printed on the tin plated tinplate and cured by high temperature baking, so that a layer of polymer protective coating is adhered to the surface. Compared with tinplate, coated tinplate can provide better corrosion resistance.

Materials and uses for electrolytic tinplate coil inner coating:

The milky white or colorless paint appearing inside the tinplate is a special material. The tinplate is coated with this special material when it is made to prevent the contents from eroding the inside of the tinplate and prevent the contents from being contaminated. Can effectively extend the storage time of the contents. On the tinplate of foods such as cookies and candy, you can clearly see that applying this layer of decorative material not only plays a role of decoration and prevents corrosion, but also effectively protects the tinplate from being scratched by sharp external objects Causes rust. This material used for painting inside the tinplate box has the characteristics of non-toxic and harmless, no odor, good adsorption, good adhesion, good flexibility and good corrosion resistance, and also has good high temperature resistance In the case of tinplate box heating at high temperature, no harmful substances will be generated, and the original gloss and other characteristics of the tinplate box will not be lost.

In fact, this kind of material used for painting inside the tinplate box is generally phenolic resin coating, epoxy-phenolic resin coating, acrylic resin coating and other materials. These coatings generally use amine curing agent, which is an acid-resistant material. This is also the main reason why tinplate boxes are heat-resistant, non-decomposable, and resistant to corrosion.