Specification of Metal Tin Printing For assorted nuts Tin Box:

Product name | Metal Tin Printing For assorted nuts Tin Box |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.20~0.28mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

Internal coating | White coation or Gold lacquer |

Outside printing | White coation+CMYK Printing+transparency lacquer |

Application | For any packing Tin, Box, Can, Bucket, etc(Food,assorted nuts in tins, oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

Printing For tins of nuts

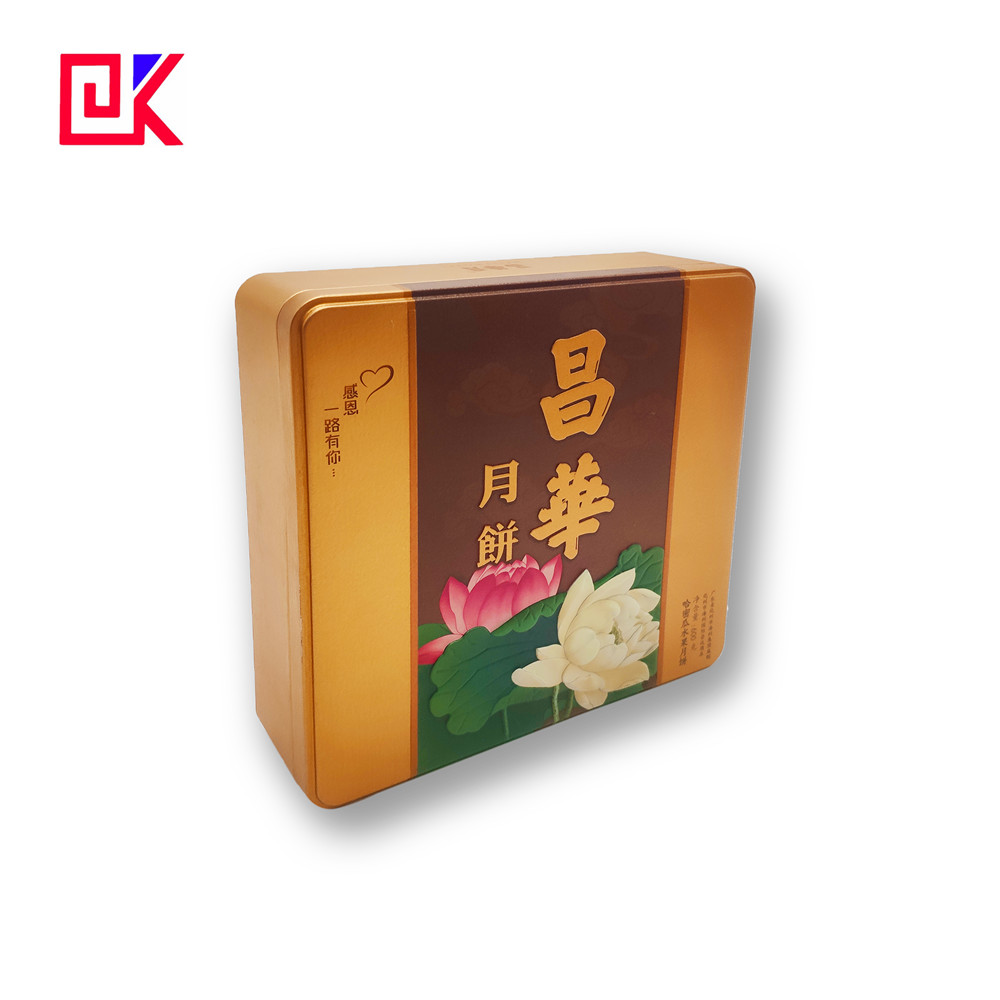

Product Show

Product Title

Product Title

Product Title

Product Title

Product Detail

Product Detail

Standard for metal tin temper:

Standard Material | Q/BQB 455-2009 | JIS G3315-2008 | ASTM A623M-08 | EM 10202:1989 | EN 1020:2001 | ISO 11950:1995 |

Single Reduce | - | T-1 | T-1(49) | T50 | TS230 | TH50+CE |

T-1.5 | - | - | - | - | - | |

T-2 | T-2 | T-2(T53) | T52 | TS245 | TH52+CE | |

T-2.5 | T-2.5 | - | - | TS260 | TH55+CE | |

T-3 | T-3 | T-3(T57) | T57 | TS275 | TH57+CE | |

T-3.5 | - | - | - | TS290 | - | |

T-4 | T-4 | T-4(T61) | T61 | TH415 | TH61+CE | |

T-5 | T-5 | T-5(T65) | T65 | TH435 | TH65+CE | |

Double Reduce | DR-7M | - | DR-7.5 | - | TH520 | - |

DR-8 | LR-8 | DR-8 | DR550 | TH550 | TH550+CE | |

DR-8M | - | DR-8.5 | - | TH580 | TH580+CE | |

DR-9 | DR-9 | DR-9 | DR620 | TH620 | TH620+CE | |

DR-9M | DR-9M | DR-9.5 | DR-660 | - | TH660+CE | |

DR-10 | DR-10 | - | - | - | TH690+CE |

Tin coating on metal tin:

Tinplate Status | Coating Status | Former Coat | Coating W. Code | Normal C-W | Min. Ave. C-W | Remarks |

EPT | Equally Coating (E) | 10# | 1.1/1.1 | 1.1/1.1 | 0.9/0.9 | All specifications |

20# | 2.2/2.2 | 2.2/2.2 | 1.8/1.8 | |||

25# | 2.8/2.8 | 2.8/2.8 | 2.5/2.5 | |||

50# | 5.6/5.6 | 5.6/5.6 | 5.2/5.2 | |||

75# | 8.4/8.4 | 8.4/8.4 | 7.8/7.8 | |||

100# | 11.2/11.2 | 11.2/11.2 | 10.1/10.1 | |||

Classified Coat (D/A) | 25#/10# | 2.8/1.1 | 2.8/1.1 | 2.5/0.9 | ||

50#/10# | 5.6/1.1 | 5.6/1.1 | 5.2/0.9 | |||

50#/25# | 5.6/2.8 | 5.6/2.8 | 5.2/2.5 | |||

75#/25# | 8.4/2.8 | 8.4/2.8 | 7.8/2.5 | |||

75#/50# | 8.4/5.6 | 8.4/5.6 | 7.8/5.2 | |||

100#/25# | 11.2/2.8 | 11.2/2.8 | 10.1/2.5 | |||

100#/50# | 11.2/5.6 | 11.2/5.6 | 10.1/5.2 | |||

100#/75# | 11.2/8.4 | 11.2/8.4 | 10.1/7.8 |

Application:

the printed tinplate can be made into boxes, cans, barrels and other containers of various specifications by welding, sealing or stamping. Is widely used in the manufacturing of metal packaging for food, tea, cosmetics, health products, medicine, gifts and other fields.

Quality assurance:

1) The Right Material, First Time: Quality is the hallmark of our reputation.

2) Strict quality control,ensure any product satisfied with yours application .

3) Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department

What is metal tin printing?

Metal tin printing is to print patterns on tinplate (tin-plated sheet). It mainly uses the physical properties of water and ink to repel, and uses printing pressure to transfer the printing text to tinplate through a blanket, which belongs to the principle of lithographic offset printing. This process has special requirements for inks.

Three factors affecting the quality of metal tin printing:

Stability During Printing: Consistency refers to how much variation is acceptable between individual sheets. As the number of prints increases, variables such as printing time, plate wear, or machine interruptions can affect print quality. Maintaining consistent print quality throughout the run, especially after reprints, is crucial.

Reproduction Accuracy: After finalizing the design, printing method, ink, and materials, technical factors influence how accurately the design is reproduced. This includes image clarity, color reproduction, gloss, and texture. Some aspects, like color balance, can be measured and controlled, while others, like reducing moiré patterns or achieving the right gloss, rely on technical expertise.

Visual Appeal: Printed materials are ultimately judged by their aesthetic impact. Design elements such as font selection, color schemes, and layout play a significant role in the visual quality. Good design balances aesthetic appeal with technical constraints to produce visually pleasing and effective printed products.

These factors together ensure high-quality, visually appealing, and consistent metal tin printing.

FAQ

1). What is minimum order quantity?

A: The MOQ is about 2 tons for each size, but it is flexible, we would consider customer's requirement.

2). What kind of terms of payment?

A: Usually payment terms,L/C,T/T,etc.

3). Could offer us samples?

A: Yes, we can offer the samples within two working days, but if the samples are customized or special coatings, it may take more time.

4). Can you do Customization & Reproduction if I provide a sample?

A: Yes, we do Customization & Reproduction service.

5). Is the packaging safe and arriving in good conditions?

A: Yes, safe Packing guarantee , all the products will arrive at your door under good conditions.

We response to problem of shipping if there unfortunately is.

6). How long does it usually take to deliver the product?

A: We will make the shipment to you immediately. It will take about 20 to 40 days arrive worldwide. It depends on the order quantities and specifications.