Specification of Tin Plate Printing For Candy Orange Tin:

Product name | Tin Plate Printing For Candy Orange Tin |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.20~0.28mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

Internal coating | Gold lacquer and transpancy lacquer |

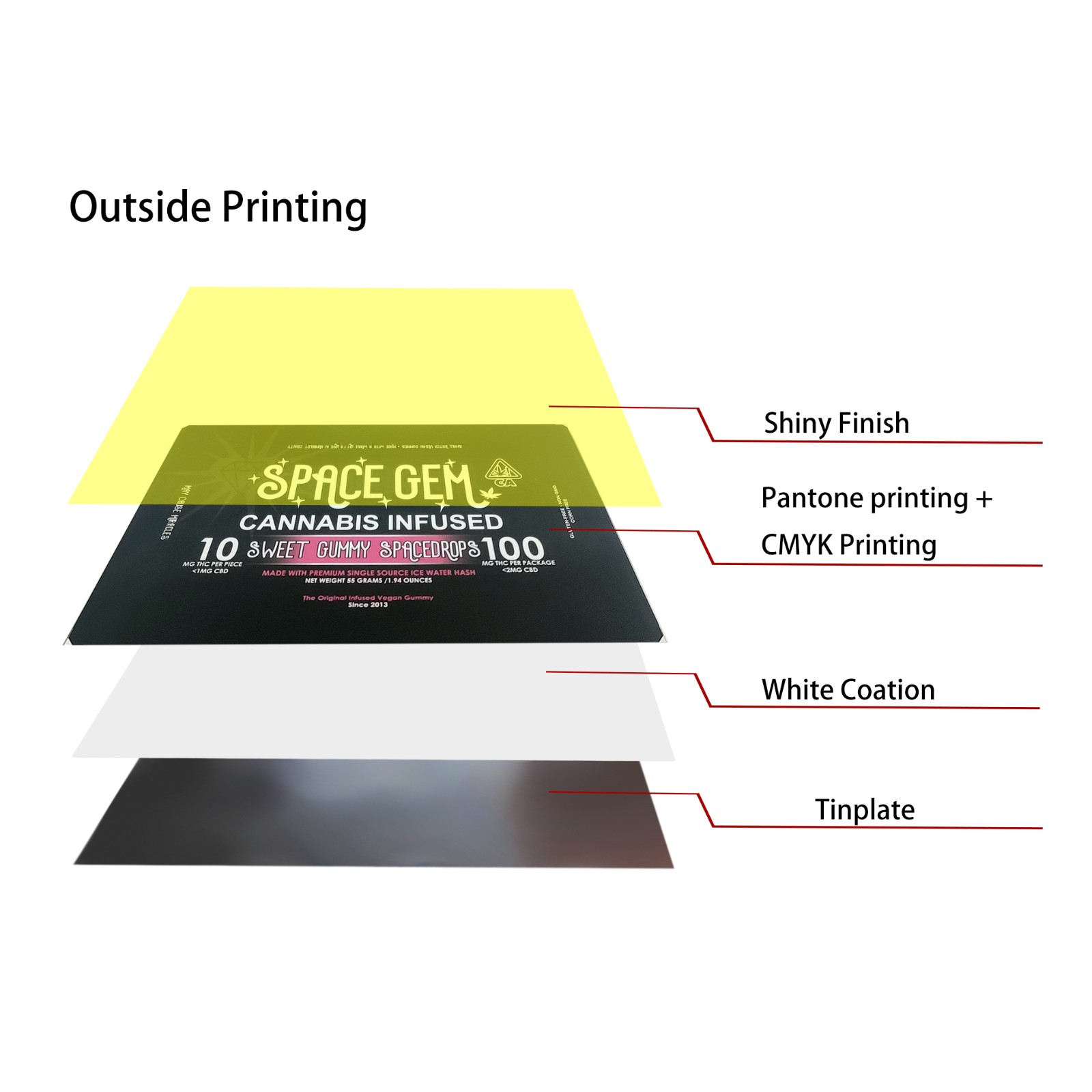

Outside printing | White coation+CMYK Printing+transparency lacquer |

Application | For any custom tins packing Box, Can, Bucket, candy tins etc(Food, oil, candy,medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Printing Show

Printing Detail

Applicatiion

Product Show

Outside Printing

What is tin plate printing?

The tin plate printing process that uses hard materials such as metal plates and metal foils as substrates is called metal printing. Since the former metal printing substrates were mainly tin plate, it is also called tin plate printing. Although there are many types of substrates, Such as tin plate (tin-plated steel sheet), chemically-treated steel sheet (non-tinned steel sheet), chrome-plated steel sheet, zinc iron sheet, black steel sheet, aluminum plate, aluminum foil, aluminum stamping container, aluminum-tinplate composite material, etc., but tinplate is still used The title of printing is also called iron sheet printing.

Tin sheet can be divided into several types according to material:

1. Tinned sheet steel (also known as tin plate, tinplate)

2. Chrome-plated steel sheet (referred to as chrome-plated sheet TFS)

3. galvanized sheet steel (commonly known as tinplate)

4. low carbon thin steel plate (commonly known as black iron sheet)

Introduction as below:

1. Tin plate

Tin plate steel sheet (also called tin-plated sheet, tin plate) is a traditional can-making material, and it is the most widely used metal packaging plate. It is tin plated on both sides of a low carbon steel sheet.

1) Performance characteristics:

① It has a bright appearance, good corrosion resistance and can processing performance, easy to weld, suitable for coating and iron printing.

② Its drawing performance is not as good as aluminum plate. Most of them are made into three-piece can structures formed by welding and rolling, and can also be made into drawn pots.

2) Structure of tin plate steel sheet

The structure of tinned thin steel plate is composed of a steel substrate, a tin-iron alloy layer, a tin layer, an oxide film and an oil film.

3) Production process of tin plate steel sheet

① Acid plating production process ② Hot dip tin plating process

4) Standard for tinned sheet steel

① Standards and codes of common tin-plated sheet steel

② Classification and representation of tin plate and steel strip Example of code mark:

Steel plate E2-T57-G-H-Q-I-0. The meaning is: equal thickness tin plating amount E2, hardness grade T57, surface condition G, passivation method H, oiling amount Q, surface quality I, size 0.

25 × 712 × 508-GB2520-88 The meaning is: The standard is GB2520-88.

5) The main technical indicators of tin plate steel sheet

①Type of steel substrate

②Specifications: thickness, width and length of the board

③Tin plating amount: Mass display of tin plating per unit area

④Tempering degree: indicates the comprehensive mechanical properties of tin plated steel sheet

4) Tinned steel sheet packaging unit

The internationally used tinned steel sheet packaging unit is the "base box". A "base box" is an area unit. A base box contains 112 pieces of tin-plated thin steel plates with a size of 335.6mm × 508mm, with a total area of 20.23㎡.

5) Coatings

The role of coatings is to isolate the can wall from the contents, prevent corrosion and prevent the dissolution of heavy metals such as lead, iron, zinc, etc. to cause pollution to foods and other contents.

① Coating requirements in the can, The coatings in the can must meet the following requirements: The coating is an organic compound, and the main components are oil and resin.

② The coating layer isolates the article from the tinned layer and makes direct contact with the article. Must have the following characteristics:

Ⅰ. Non-toxic, odorless, odorless;

Ⅱ. The coating film is dense, basically free of pores, and has good corrosion resistance;

Ⅲ. The coating film does not fall off when subjected to impact, folding, bending and other processing;

Ⅳ. Does not zoom during high-temperature welding Shedding without dissolution of harmful substances.

8) Application of tin plate

① It is widely used in the canning industry to make cans, tins, boxes for packaging cosmetics, candy, biscuits, tea, milk powder, etc.

② It is a good capping material for glass, plastic and other bottles.

2. Chrome-plated steel sheet,

Chrome-plated steel sheet (referred to as chrome-plated sheet) is a tin-plated sheet substitute material developed in the early 1960s to reduce the use of heavy metal tin and reduce costs. The steel plate is made of chrome, which is one of the materials for making cans.

3. Galvanized sheet steel

Galvanized sheet steel (commonly known as tinplate) is one of the can making materials.

4.Low carbon thin steel plate

Commonly known as black iron sheet, packaging steel is mainly low carbon steel sheet with carbon content less than 0.25%.

What are the characteristics of tinp late printing?

Tin plate printing belongs to offset printing, but has its own characteristics different from general offset printing.

① The substrates printed by tin plate are various metal sheets. At present, tinplate printed substrates are usually tinned sheet steel (also known as tin plate), chrome-plated sheet steel, ordinary sheet steel, and aluminum alloy sheet.

According to the different hardness of these metal sheets, the adjustment of the roller pressure is the key to operation. In addition to printing, it can be divided into three types: hard iron, neutral iron, and soft iron. Aluminum alloy sheet is soft, ordinary sheet steel is neutral, and chrome-plated sheet steel is rigid. In the printing process, it is necessary to adjust the cylinder pressure and select the appropriate lining material depending on the hardness of the substrate.

② Coatings play a decisive role in the quality of tin plate prints. The coating can increase the adhesion between the tin plate and the ink layer and protect the ink film layer.

③ Use special printing ink. As the surface of tin plate printing substrates is smooth and does not have the ability to absorb, tin plate printing inks rely on oxidized conjunctiva and volatilization to dry.

At the same time, tin plate prints are generally used in cans after printing, which requires that the printed iron inks are resistant to high temperatures and cooking, and non-toxic.

④The printing operation is different from general offset printing. When manufacturing the printing machine, the blowing force of the blowing nozzle and the suction force of the mouthpiece should be considered, and a horseshoe magnet should be added at the feed to overcome the adsorption force between the tin plates.

Surface Finish on tin plate printing:

Single Reduce | B | Bright Surface | Glazed surface obtained a thin layer of chromium and chromium oxide which deposits on the smooth. |

Double Reduce | R | Stone Surface | Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone figures. |

S | Silver Surface | Glazed surface obtained after melting treatment of electronicned raw material strip with rough matt surface. | |

M | Matte Surface | Matte Surface | |

R | Stone Surface | Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone figures. |

Tin plate raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of steel can be extracted from 1.8 ton of iron ore

Production capability:

1) Our company have two factories:one is tinplate coating and printing, and the other is tin can making , can supply one-stop service from plain tinplate, coated tinplate ,printed tinplate ,lacquered tinplate till the final tin cans.

2) Smooth production ability 4,000tons each month .

3) OEM/ODM , Free of charges of Logo design and printing on your goods .

Application:

the printed tin plate can be made into boxes, cans, barrels and other containers of various specifications by welding, sealing or stamping. Is widely used in the manufacturing of metal packaging for food, tea, cosmetics, health products, medicine, gifts and other fields.

Equipment from the Japan company:

Our tinplate is coated and printed using equipment from the Japan company “FUJI“:there are 5 production lines for coating and printing, it has an efficiency of 6,000 plates per hour.Our tinplate printing has resolution of 170 LPI. We only use high quality for food packaging.there are always raw materials in our warehouses, which allows for continuous production 7 days one week.