Specification of Transparency Lacquer Coated On Plain Tin Plate:

Product name | Transparency Lacquer Coated On Plain Tin Plate |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA(Batch annealing),CA(Continuous annealing) |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.15~0.45mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

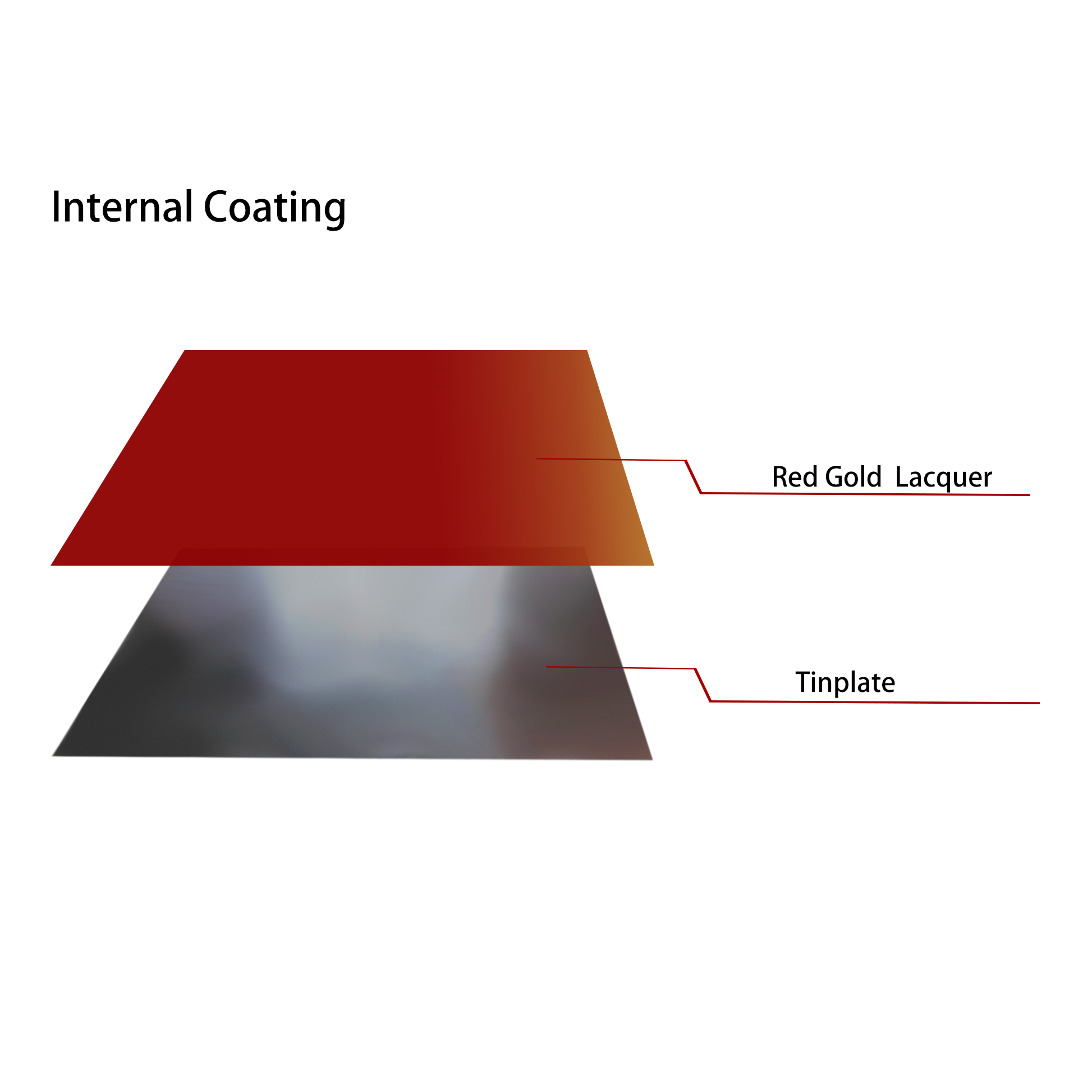

Internal coating | Gold lacquer /transparency lacquer |

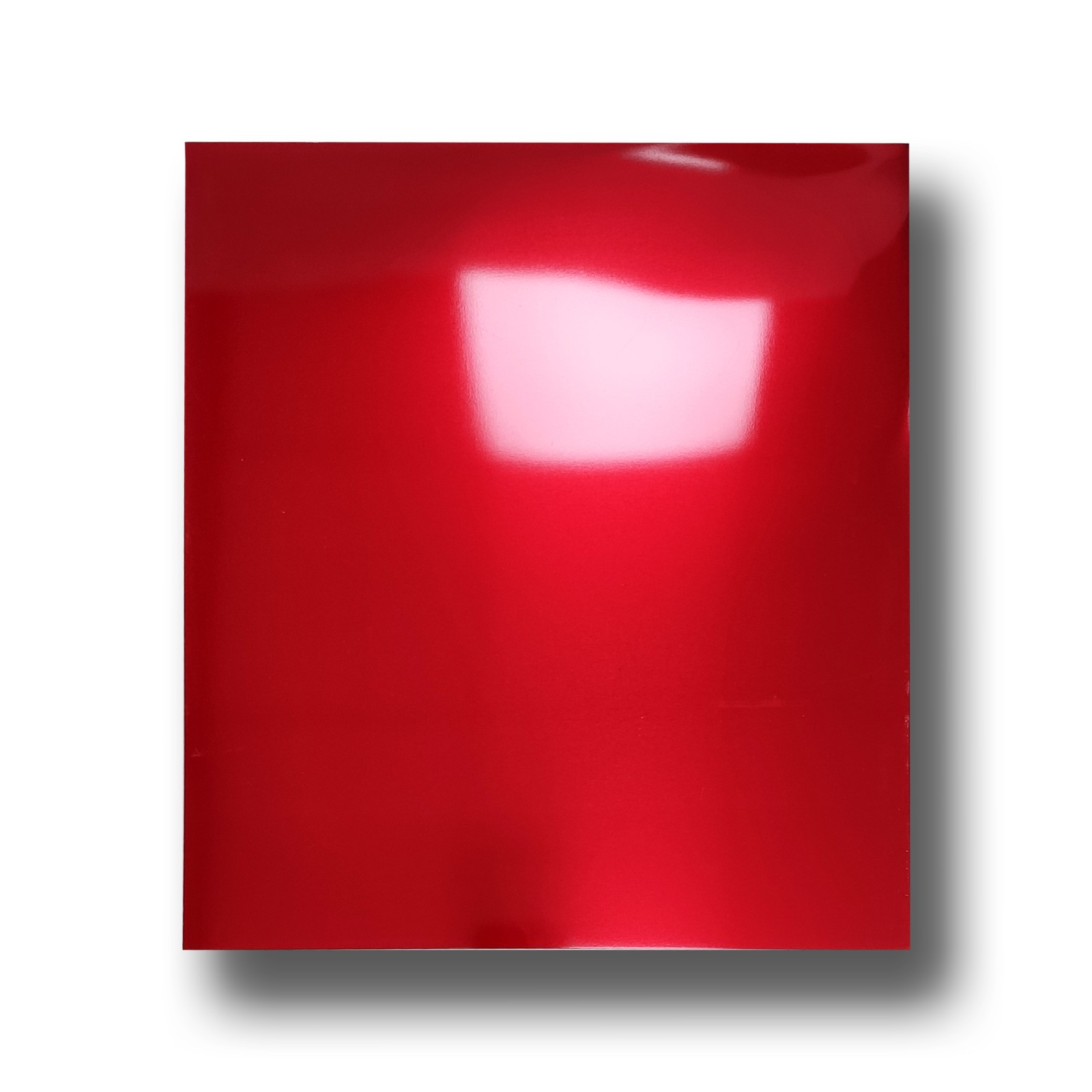

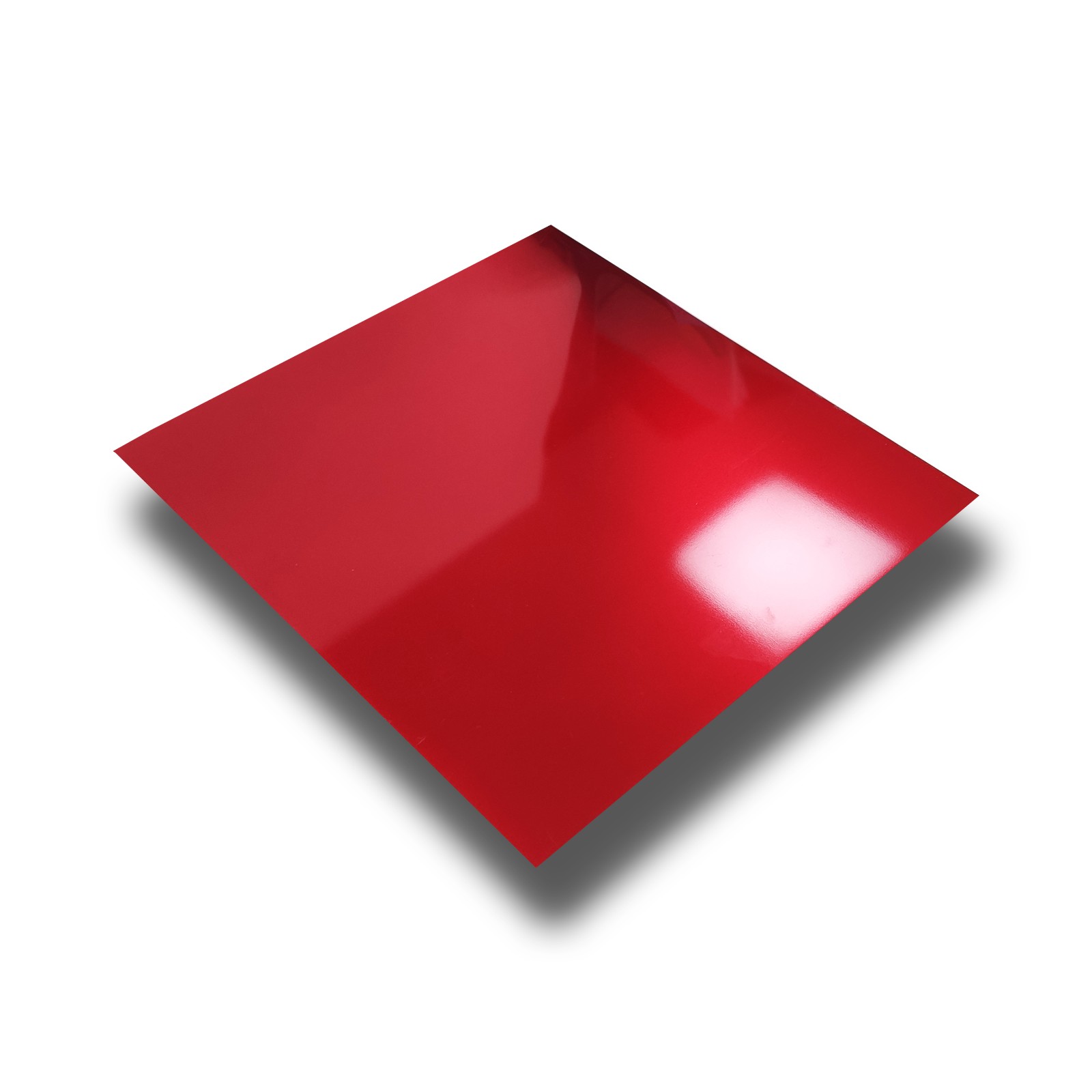

Outside coating | Shiny finish/matte finish |

Application | For any packing Box, Can, Bucket, etc(Food, oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 5000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

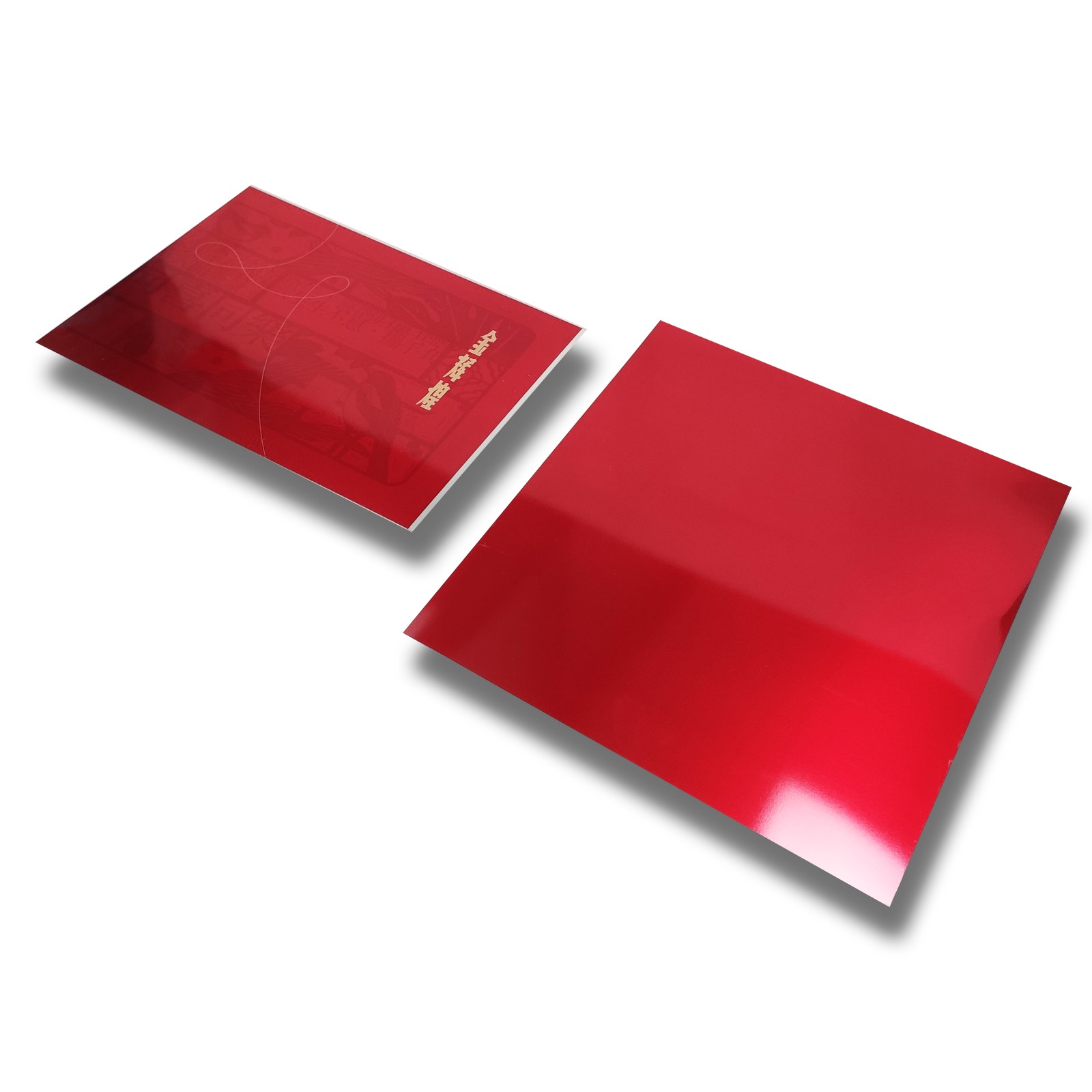

Printed Tinplate

tin plate metal Printing show

Printing Detail

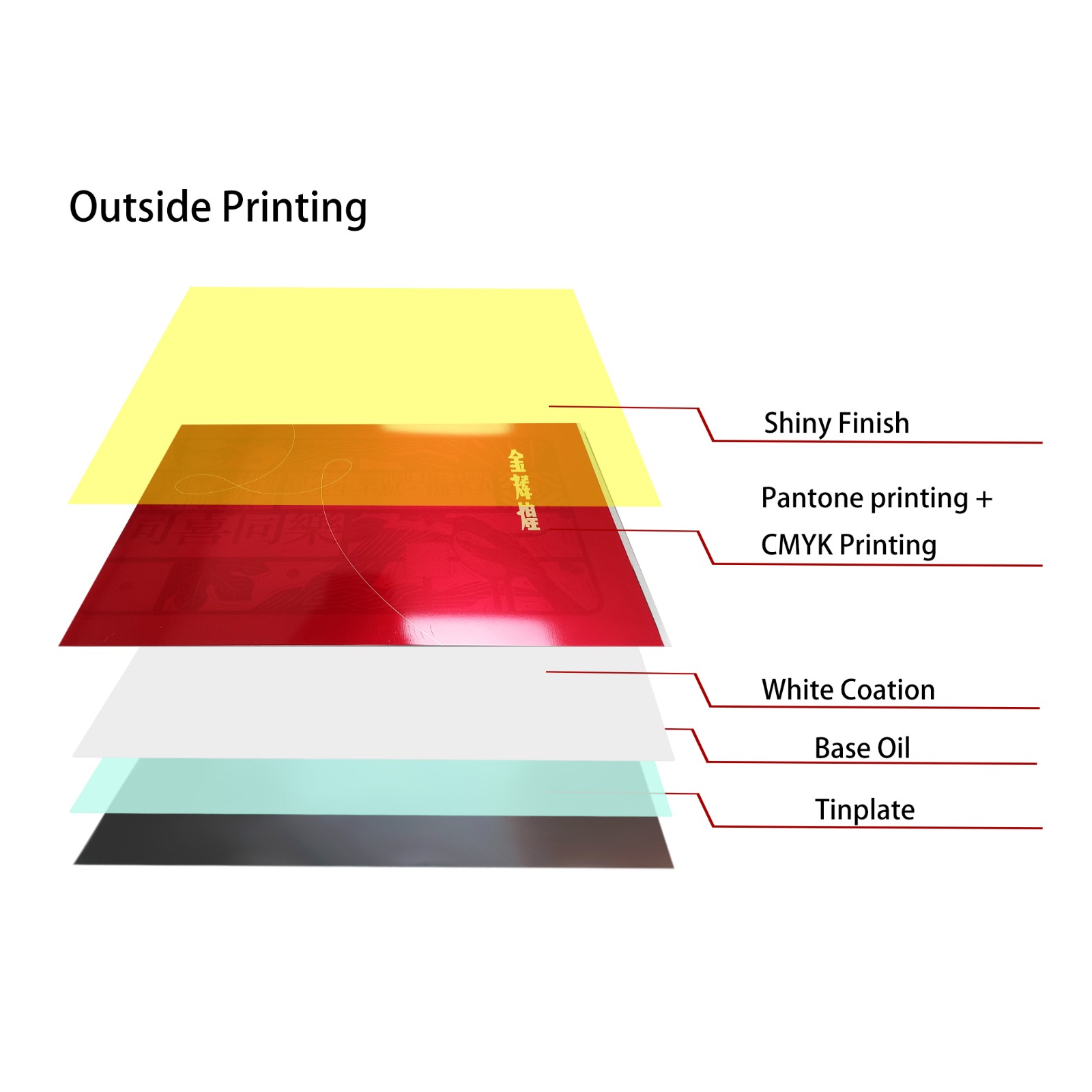

Outside Printing

Internal Coating

All of our products support customization, if you need please feel free to contact us.

Standard for Tin plate Temper:

Code | Chineses | Japaness | American | Europen | International |

GB/T2520-2000 | JIS G3303-2002 | ASTM | DIN EN | ISO | |

T-2 | TH52+SE | T-2 | T-2(T53) | T52 | TH52+SE |

T-2.5 | TH55+SE | T-2.5 | TH55+SE | ||

T-3 | TH57+SE | T-3 | T-3(T57) | T57 | TH57+SE |

T-3.5 | |||||

T-4 | TH61+SE | T-4 | T-4(T61) | T61 | TH61+SE |

Surface Finish on coated and printed tin plate:

Marks | Suface state | Characteristics | |

Single Reduce | B | Bright Surface | Glazed surface obtained a thin layer of chromium and chromium oxide which deposits on the smooth. |

Double Reduce | R | Stone Surface | Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone figures. |

S | Silver Surface | Glazed surface obtained after melting treatment of electronicned raw material strip with rough matt surface. | |

M | Matte Surface | Matte Surface | |

R | Stone Surface | Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone figures. |

UV printing and coating process for food cans.

Product Show

Printing Detail

Coating Detail

Product Detail

It is characterized by including the following steps:

1) Pre-press document production. Pre-press professional plate-making software is used. For the main part of the product document, the main color tone of the product field is round dots, the dot angle is 45 degrees, and the dot percentage is replaced by 90% to 95% to form a bitmap file. ;

2) Make the plate directly offline, upload the formed bitmap file to the computer plate making machine, and expose and expose the plate on the heat-sensitive plate. The time of plate exposure is 2 ~ 3 minutes;

3) Internal coating, using epoxy amino or epoxy novolac internal coating on the inner surface of tinplate, the coating thickness is 5g / m2 ~ 6g / m2, coating speed is 80 ~ 90m / min, curing temperature is 195 ° C ~ 205 ° C, curing time 10 ~ 15 minutes;

4) Outer coating, using polyester or acrylic resin type coating on the outer surface of tinplate, the coating film amount is 10g / m2 ~ 12g / m2, the coating speed is 80 ~ 90m / min, and the curing temperature is 175 ° C ~ 185 ° C, curing time 12 ~ 15 minutes;

5) Six-color UV printing. The printed PS plate is installed in each printing color group of the printing machine. The printing color sequence is yellow, skin color, spot red, blue, spot red, and black. The tinted red is a tinplate food can. The main color, the fifth color sequence spot red is 90% ~ 95% dot percentage;

6) Curing, use UV lamp group for continuous curing, UV lamp power is 160w / cm ~ 200w / cm, the lamp power is 100%, to ensure the ink curing;

7) Varnishing, use acrylic or vinyl varnish with high temperature resistance for vertical varnishing, simulate overcoating, and apply varnish in the area of printed graphics. The amount of coating film is 6g / m2 ~ 7g / m2 , Coating speed 80 ~ 90m / min, curing temperature 185 ° C ~ 195 ° C, curing time 12 ~ 15 minutes, complete the printing and coating of the tinplate food can

Quality assurance:

1) The Right Material, First Time: Quality is the hallmark of our reputation.

2) Strict quality control,ensure any product satisfied with yours application .

3) Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department

Certificate: Approved by the ISO 9001